Drovokol do it yourself Instruments

In the old days, many labor processes, including the cutting of firewood, were made manually, but today there has been a modern technique that facilitates and accelerating them at times. So all the familiar ax changed the device called woodcut.

Classification of woodcuts

Mechanisms for rods of firewood are:

- for home use. Such devices are used only to split logs;

- for professional use. Often these are whole machines capable of not only splitting firewood, but also feed the logs, to penalize them at the desired length, all the split lamps. They are more expensive, powerful and large than those designed for home use.

Warrinding mechanisms vary:

1. In the direction of the filing of the split-in full:

- horizontal - separated piece of log falls on a horizontal chute. The ring occurs according to the following scheme: or it is pushed by a special device to the knife, or the knife is approaching the linen lying on the spot;

- vertical - Called is installed vertically, and the knife approaching it presses from above. This type of device is more productive than the first, but periodically arises the need to manually maintain the log. At the same time, the safety rules should be strictly followed. Such firewoods are usually used in production purposes;

- mixed - these are also machines for professional use, combining functions and horizontal and vertical devices.

2. By type of power supply:

- wood splitters are equipped with electric motors. These devices are the simplest of all. They were forced to work the hydraulic pump. Electric wood splitters are not required to prepare for work, as well as some special services. Their only disadvantage is binding to a power source. Mainly they are used for domestic purposes;

- wood splitters, running on gasoline or diesel fuel. They have much more power than electric models. Often used for industrial logging, as well as owners of private houses;

- devices operating on a tractor-drawn. They are connected to the tractor's hydraulic system or to its power take-off shaft. Such splitters have great strength. They are successfully used on farms, forestry, enterprises;

- wood splitters are equipped with a combined engine. They combine different types of drives. The following combination: an electric motor and tractor thrust; + tractor traction engine that runs on gasoline.

3. According to the degree of mobility:

- permanently installed industrial wood splitters are too massive and heavy, in order to move them;

- mobile wood splitters are equipped with special wheels, with which you can change their location.

4. According to the principle of work:

- hydraulic cleaver. Hydraulic pump causes the knife to press on a piece of wood with great force, causing it cracks;

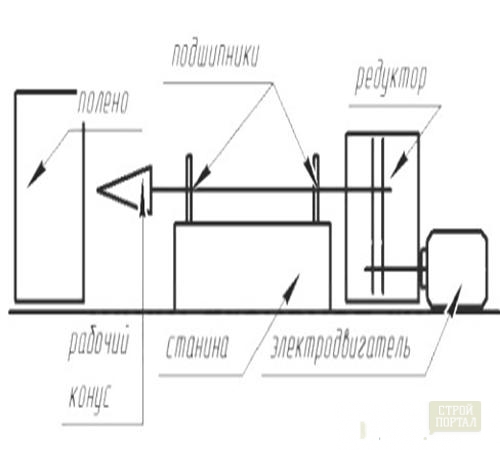

- cleaver cone. In this device, the knife is replaced by a cone, equipped with a thread. He rotates and is screwed into the log and splits it.

If you decide to build a cleaver with his hands, then we should consider the model with such principle work. It is best suited for individual processing.

Technical parameters splitter devices

- power, which will be split logs. I used at home drovorubov it ranges from three to seven tons. The nozzle should rotate at a speed of 400 to 600 rev / min;

- the maximum length of the logs, which are capable of splitting the particular device. In domestic units it is up to half a meter;

- diameter billets, which can operate cleaver. Maximum mechanisms for household - 30 cm;

- piston speed operation, by which the amount of time will depend on the outgoing FIREWOODPROCESSORS. Domestic wood splitters are moving forward at a speed of 4 cm / sec ago - 7 cm / sec.

How can I make a cleaver

Not every dacha in need of woodcap can afford to lay a round sum for a purchase device. In this case, you can make the simplest model for home use with your own hands. Drovokol homemade - a budget option, a worthy replacement for shopping.

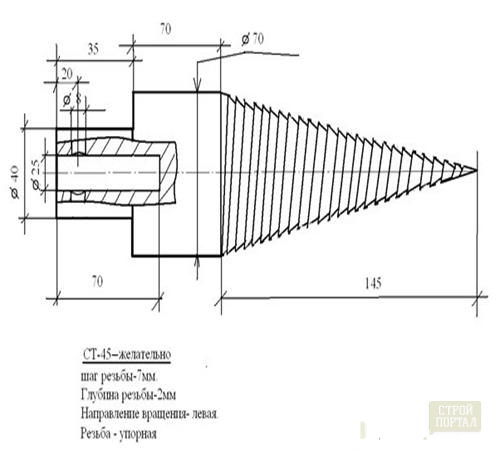

- The most complex part of the conical design is a cone that screws into full and splits it. This item will have to be pulled out on the lathe. Drawing of wood and cone is shown below.

- After the cone is made, it should be cut into the left resistant thread. If you do not have a lathe, and there is no possibility to order the manufacture of details, you can use the grinder. To do this, set the grinder from the metal to the pulley of the electric motor, and when it starts rotating freely, simply remove the metal equally from all sides.

- When the cone is ready, put it on the shaft, equipped with the bearings of the desired size. At the end of the shaft, you need to put the flange with an asterisk from the motorcycle wheel in advance. Cone with threads. Fasten the pins or bolt. If suddenly watches, you can easily remove it from the shaft or turn out from the gas key.

- If you fix the cone on the shaft without the possibility of removal, then if it is embedded, you will have to remove the drive chain, because The motor of the electric motor can sometimes be rotated in the opposite direction.

- From pipes and 2 nuts build a strut and insert it into the gap between the shaft and the engine. With it, the chain will stretch.

- If there is a desire, instead of an electric motor, install a gasoline unit from the motor-block, the power of which is not less than 6 hp. But it should be remembered that the most suitable for cone structures are engines, the capacity of which is at least 2-3 kW, making 250 or more revolutions per minute.

Creating homemade woodcut, it is necessary to take into account some moments:

- do not connect the nozzle with the engine directly. It is dangerous due to a large number of revolutions;

- so that the homemade firing has optimal performance, the nozzle must rotate at a speed of at least 250 rpm;

- belt or chain transmission must be clothed in a protective cover;

- all work related to electricity should produce a professional.

If you decide to independently make a woodcut, the video located below illustrates the actions described above.

New comments

Add a comment

To send a comment you need authorize.

with solid rocks x what a hundred pounds comes out

Perezolol is a huge bunch of birch firewood for half an hour.

put the engine 3kvt but connected 220V approximately 2 kWh all through the clinorem transmission, everything would be fine, but for some reason it is not enough power, what's the matter? Or something wrong?