Replacing wooden floors Floors

40 years ago, the floors in the houses were solid. After such a long service life, they simply need a replacement.

Content

The replacement of wooden floors consists of four stages:

Disassembly of an existing coating

Performing a dismantling of a wooden floor in an apartment and a concrete screed under it, you must be extremely careful. An error may damage the electrical wiring of the neighbors, because your gender is their ceiling. Therefore, physical strength is important here, but also knowledge of the design is very useful. So:

- we store tool: hammer, scrap, nail, screwdrivers, saw;

- take scrap and tear the plinth;

- we remove nails and screws connecting the floor with lags;

- we remove all wear boards, starting with the smallest. Moving, with the corner of the room to its center.

The process of replacing the wooden floor in the apartment can be accelerated if we use a saw:

- we note where the lags are located, drawing lines on the surface of the old coating;

- we retreat from the location of the nails per centimeter 2 or 2.5 and spend a straight line again. Marking is ready;

- we perform a hole for entering the saw and proceed to dismantling. It will be even faster if the electric jigsik is used instead of the saw.

Selection of replacement and material option

Starting work on replacing old wooden floors, it is important to decide: what do you want to have on the finish? This solution will be the starting point for the selection of material and the technological process. An important role is also played by the foundation:

- if you want to arrange a tiled floor, it can be not perfectly smooth, but dry and durable;

- if the wooden floor is replaced on the laminate, parquet or linoleum, then the requirements will be tougher: the ideal evenness, the absence of amusements and shells.

Chernob's device

The type of rough base, the technology of its device depends on the choice of the main coating.

Wooden floor replacement on concrete

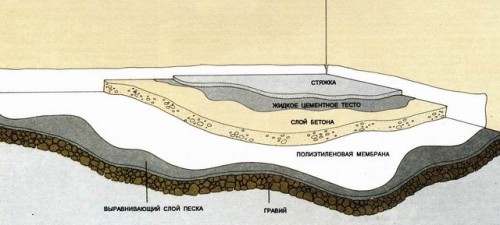

Concrete floor consists of several layers:

- stone - 10 cm;

- sand - 5 cm;

- waterproofing and thermal insulation - 5 cm;

- reinforcing mesh;

- concrete - 10 cm.

Stone layers and sand equal to a shovel. The waterproofing gasket is stacked, the edges of which should perform above the floor level. New layer - thermal insulation stove. The turn of the reinforcing grid approached. Now a solution of concrete:

- armed with a shovel, begin to align it from remote corners to the door. The surface of the surface is controlled by the rule, and the protruding insulation edges replace the guides;

- we leave it all for pouring;

- when concrete froze, pour a self-leveling solution on the surface.

Wooden floor replacement on concrete performed. You can lay coating.

Final finish

Consider using one of the options:

Wooden floor replacement on laminate

When choosing this option for replacing the wooden floor, the price will be more democratic, as the laminate is cheaper than parquet or parquet board.

Any reason for it will suit any: be it a concrete screed or a wooden floor. The main thing is that it was arranged firmly, did not fade and did not creak. With the old boarding coating you need to do the following:

- disassemble

- eliminate the height differences in the level. May have to reduce the distance between them, by installing additional;

- board;

- to lay on top of plywood sheets with a thickness of 12 to 15 mm;

- on the plywood to lay the substrate. It is better environmentally friendly: cork or parkolag. Good cork substrate release:

- in Portugal - Acousticorc;

- in Spain - CORK-2000;

- in Germany - Dazu.

- Tuplex (Tuplex), produced byFXX the Finnish company of the same name, although synthetic material, but very reliable.

That natural parquet, which laminate is stacked on the same technology using special glue. Do not forget about the gaps between the elements. Their value is from 7 to 15 mm. The panels are easier to stick, if the lock is rotated to you.

As for the quality of the laminate, then, of course, among companies selling this kind of coating, it is better to stay at Pergo, Tarkett, Quick, Step or Egger.

Replacement floors in a wooden house

In a wooden house, usually, the floors are changed, when all the cracks begin to blow, and the boards are completely creaked, or even fall. As in the case of the apartment, the first thing is removing the board. Technology and tools are the same. When it becomes clear, in what condition is the overlap, you can proceed to drafting the estimates on the replacement of the wooden floor. Most often, the logs must be dismantled.

What will be needed for the device of the new floor:

- dry ram 20x20 cm;

- parchment as a substrate for thermal insulation;

- heat insulation. In wooden houses, it is often used, the so-called stone wool Rockwool (Rockwool);

- antiseptic for wood;

- fasteners: self-tapping screws, galvanized plates;

- foam for mounting.

Getting to install overlapping

Lags will lie strictly horizontally on the foundation. Under them you need to raise the ruleroid. Along the walls perpendicular to the lags, we put the pieces of the bar, impregnated with an antiseptic. We connect them with the help of construction corners and screws, as a result of which the design will be closed. In the gap between the walls and it is poured not a thick solution.

Lower floor

To put the insulation, you need the bottom floor. The thickness of the boards for it is 2-3 cm. They are screwed up with self-reserved bars. Then:

- the cracks are blended by mounting foam;

- the insulation is stacked.

Upper floor

For its device, it is better to buy a board from 40 mm - well dried. Bashed it will have to be the same self-draws. When the upper floor is not in the black, do not hurry to lay the coating on it. Let him get a month in such a state. During this time, the boards are lying, you pull the fastener, put on top of Phaneur, and everything you wish for: Linoleum, laminate, parquet or something else.