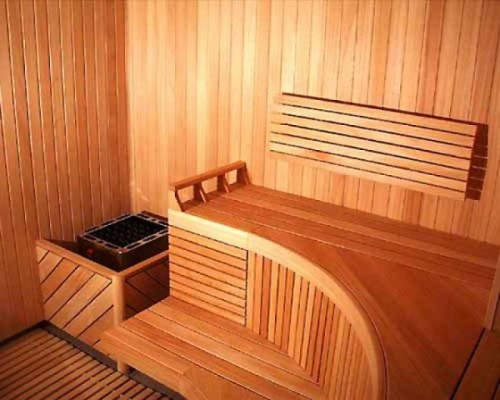

Bath finishing materials inside Baths, saunas and pools

Not only a pleasant pastime, but also your health depends on the interior. The main commandment during concluding works on the construction of the bath is "not harm!".

Content

The bath has always been famous for its wellness effect. Properly selected materials for trimming baths inside will help keep health and good mood.

Requirements for materials for the interior of the bath

In our homes and apartments more than enough materials and objects that identify chemicals. Try to make the bath becoming an environmentally friendly island among your buildings.

Ban trim materials must first be safe. Forget about linoleum, chipboard, moisture-proof plywood, glued from several layers of chips, PVC panels. At elevated temperature, which in the bath is inevitable, these materials allocate harmful chemicals.

The second criterion is practicality and durability. A cheap material that has a short service life will ultimately cost more for the reason that after 3-4 years it will require replacement.

Pay attention to the quality of wood processing. Lining or block house should be carefully grounded to a smooth surface.

Warming and insulation

For insulation and insulation, the bath will be required:

- The folgized insulation consists of three layers - polished aluminum foil, plastic film and craft paper. The foil helps to keep heat and prevents steam in a layer of thermal insulation.

- Basalt wool in plates or rolls - non-flammable thermal insulation material.

- Membrane for waterproofing insulation.

Finish finish

For the finish finish, the baths will be needed:

- lining or block house;

- flooring or tile;

- ceiling cartoons;

- gender basement;

- thermal protective screen for the furnace;

- thermal insulation stand under the oven or heater.

The main material is the lining for the walls of the walls and the ceiling. Different varieties of wood have their own characteristics, it should be considered when the bath internal finish do it yourself.

What wood choose for a bath

For the finishing of the steam room and the pre-tribades often use different types of wood. The combination of various shades, healing properties and flavors of the tree gives a good effect.

For the pair, chosen wood without the content of resinous compounds, with low heat transfer and standing to high temperatures and high humidity.

- Lipa has a pleasant aroma and during heating does not emit resin. It has low thermal conductivity and high moisture resistance, due to which the pair is quickly heated. A pleasant uniform light-golden tree color creates a feeling of purity.

- Aspen - very dense and durable wood. It has a beneficial effect on the joints. Resistant to rotting, fungi and mold, because It has bactericidal properties. It has a pleasant whitish color. Due to the low density, it does not heat much. It is believed that the Wood of Osin takes a negative energy. The cost is the most affordable and cheap.

- Alder has a beautiful pattern of fibers. Color - from light chocolate to pinkish. There are no resorts. It has bactericidal properties, helps with rheumatism of the joints. It has a water repellent effect. Do not dry. Pleasant, warm to the touch. The cost is one and a half times more than alder.

- Abashi is distinguished by excellent characteristics and high cost. Low thermal conductivity. Serves long. Good combined with the Canadian cedar.

- Oak, beech, ash strongly heated and have high heat transfer. Apply only for finishing a washing and pre-banner.

- Canadian cedar is a good antiseptic and heat resonator. The boards obtained from one logs have a different shade - from lemon to chocolate-brown. The Wood Canadian Cedar is rich in essential oils that have a favorable affect the upper respiratory tract. It is used to finish elite bath and not everyone is available at the expense of high cost.

- Also on sale you can meet the lining, which passed the heat treatment of the ferry. Such lining was the name of the thermiverevin. Several times more expensive than untreated lining. If you choose between the thermal and untreated Abashi, it is better to choose Abash than overpaying for the treated by ferry aspen or alder.

- Golden cedar from Africa and the aromatic cedar from Mexico have very good qualities, but almost unavailable in cost.

- Larch resistant to high temperatures and humidity. The larch wood contains a large number of resins, so it is used to build a cut. For interior decoration, larch can be used in the pre-tribbon.

- The wood of coniferous rocks due to the large resin content in the steam room does not apply.

- The assertion that the best material for the floor is oak, erroneously. Indeed, Oak is durable, but we should not forget about security. Wet oak boards are very slippery.

What to handle the lining in the bath

The desire to protect the tree from rotting is understandable. But when choosing between beauty, durability and environmental friendliness, ecology wins. In steaming lining do not proceed. Instead of the fragrance of the tree you will get the smell of chemicals. Even if there is no unpleasant smell, it will definitely not be good for health.

With a big desire, you can handle linen or hemp oil in the steam room. The oil is absorbed into the wood layer and forms a film. Film protects the tree from pollution.

The best option is to leave a steam room without impregnation and coatings, passing it right behind it - to ventilate and dry.

Wood processing is allowed in the washing and rest room.

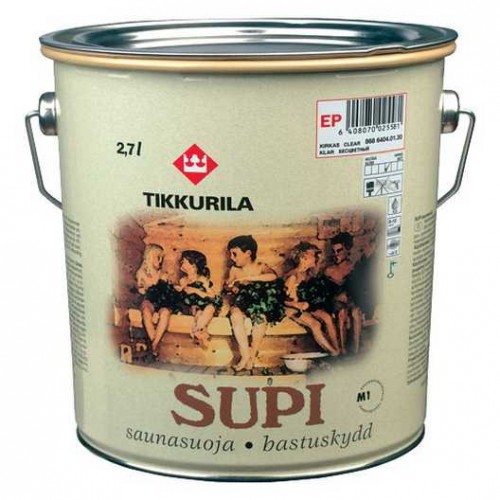

The impregnation for the Supi Saunasoja tree (Tikkurila) is popular and gives a good effect. Such an impregnation can be used to be confident that it is made in Finland, and not at the local Fabirke with violation of technology. Another aspect that should be taken into account - the impregnation is designed for Finnish dry saunas, and not for Russian steam room. The tree absorbs moisture. And then it gives it along with the chemical connections that you generously reward natural material during processing.

The cheapest impregnation of the company "Manor" - U-409. Produced specifically for baths and saunas.

The cheapest impregnation of the company "Manor" - U-409. Produced specifically for baths and saunas.

A relatively safe is an antiseptic with the wax "Eurotex-Sauna". The coating creates a colorless film on the surface, due to which the wood does not darken and is easy to clean.

Protective screens over Kamenka and tile

- If the distance between the heater and the wall is less than 50 cm, the wall needs to be protected from high temperatures. To do this, a stainless steel protective screen is installed or brickwork is performed.

- On the floor before the furnace, a sheet of stainless steel is also stacked.

- To finish the washing and swimming pools use glazed tiles. Such a tile has high strength and moves well to the temperature differences.

- The furnace and the heater are facing with clinker tiles, characterized by high heat resistance. Tile thickness from 9 to 12 mm. Angle elements allow you to beautifully arrange an outer corners.

- Outdoor tiles preferably choose with anti-slip effect. In the steam room, the floor tile is strongly heated, so wooden grilles are usually placed on the floor on top of the tile.