Wooden staircase on a metal frame with their own hands Ladder

The stairs in homes and cottages have become an integral part of the interior and, except for their basic functions, they are a good addition to the design of the room. There are stairs inside buildings to access the upper floors and in attic rooms, also from the outside.

Content

In the entire history of the development of construction technologies, the stairs have undergone significant changes. Today, various types of stairs are built in homes using a wide variety of materials, including a tree in combination with the metal.

Types of stairs

Considering the various designs of stairs, equipped in houses and cottages, you can highlight several main types:

- march using the appliance;

- screw;

- batthodes.

For the construction of march and screw stairs, metallic structures of various types have recently used. Metal is most suitable for the construction of stairs in small houses. Metal structures are durable and durable, with the right installation of wooden parts, they do not overclock over time and do not make a creak. At the cost of the ladder on the metal frame is more economical and depending on the type of tree type used for steps, can be organically fit into any interior.

Construction stairs

Install the wooden staircase in the house between the floors or to raise on the attic you can in the already caught house. Such stairs do not require special time and materials. Beautiful, wooden staircase, built on the basis of a metal frame, will be a good designer solution. Making stairs on a metal frame can be made with your own hands without attracting outsiders.

For a person who owns the skills of working with metal and wood, to build a staircase based on a metal frame will not be much difficult. It should be noted that the construction of stairs in the house is a creative process, by connecting a little fantasy, you can not only get a useful part of the house, but to make a good addition to the overall interior.

When building a staircase, various wood species can be used for steps and railings. Metal frame made, craftsmen use corners of various sections or pipes. For staining of the metal, inexpensive alkyd, acrylic paints and enamel can be used. Wooden parts are polished and opened with varnish or stain with drawing. Properly selected paint and skillfully applied pattern can turn the usual staircase into an artistic work, adorning and complementing the interior.

Calculation of frame and materials

Before the construction of a frame staircase, it is necessary to determine the type and constructive features, which materials will be used in which quantity. Therefore, first it is desirable to make a small sketch, it will help clearly understand the design features, as the staircase will be constructed.

The first thing is measured by the height of the lift, this is necessary to calculate the number of steps. For a comfortable lift, the height of the approaches should be in the range of 15 - 18 cm. Based on such data, it is possible to calculate that there are 12 steps for a staircase with a height of 2.4 m. Additional two centimeters are added to the thickness of the sticky. This is suitable for stairs with an angle of inclination of 40-450. For other types of stairs, the calculation can be corrected. However, it should be borne in mind that the height of the approach and the width of the sticking in the amount should give the length of the middle step of the person. Given such parameters, you can build a staircase with a comfortable lift.

Further are determined with the material for the manufacture of frame, railings and steps. The most suitable can be boards and butterfly ash, ash, beech, and a pipe or corner for a frame. The number of corners or pipes is determined depending on the height of the stairs, the presence of sites and additional fences. The full calculation of the metal frame of the stairs must be made by making a sketch or approximate drawing with the size of the structural elements.

When calculating, it is necessary to take into account that the material will go not only for the manufacture of the theetics, as well as the additional elements of the fastening of the steps, supporting parts of the railil. To create elements, the railings use polished wooden bars, to open them with varnish or paint the pattern, which will give the staircase an attractive look.

Making framework stairs

After drawing up the drawing (sketch) and the work of all calculations, prepare the necessary material and begin to mount the frame.

To make a metal frame stairs with their own hands, except the main material, the tools are needed:

- hammer;

- electric welding;

- electric saw with a circle for metal;

- fIRLING (for the removal of sowing);

- small or pencil.

According to the sketch, pre-marking parts. If the parts are pair, then noted on one with the help of the line, and the other is unlocked by the size of the first part. For multiple parts (fastening of steps), mark and saw the first, and the rest are cut off using it, as a pattern. Only in this case, all the details will be the same size.

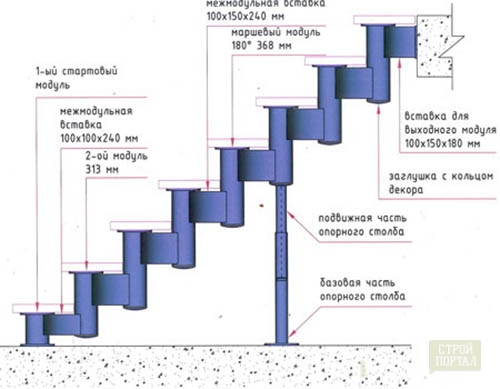

Depending on the type of selected design, the installation and assembly is started from the main carrier parts. When installing the screw staircase, first install the central support and fix in the bottom and top. If the staircase is marching, then first install and equalize the tents, fasten them between themselves at the bottom and top. If necessary, install additional supports from below and secure the wall. After installing the carrier elements, there are places, and weld fasteners.

Installation of railings, risers and commemorated after a complete consolidation of all carrier elements using screws from the bottom. Complete the construction of finishing and painting all elements.

Wooden parts of stairs

In the manufacture of stairs, the boards are 20 -30 mm thick, the boards length can vary depending on the width of the span. In the manufacture of screw stairs, special attention is paid to the form of the stage, they are cut with this calculation, which is narrowed to the central part of the width.

This form of boards is necessary for the uniform distribution of the stages. Having equipped the stairs on the metal frame, it should be noted that the form of steps largely depends on the design. For march stairs, boards are used correct, rectangular shape.

Any tree is used as a material, which is suitable for the size and required strength. Oak, beech, aspen uses especially popularity. They are a bit more expensive pine, but are considered more durable.

When choosing a tree, based on your budget. Do not forget that with proper care, any material will serve for a long time.