Wooden garage with your own hands - Tree garage Construction

The garage protects the car from unfavorable weather conditions, robbers, "neighbors-benevolers" and street animals, mostly cats that love to leave dirty traces on freshly leapped hood. With an increase in the number of cars, open guarded parking lots have gone to metal boxes. Owners of private houses prefer stone counterparts. But the first, and the second are inferior to wooden garages.

Content

Wooden garage and its advantages

The tree has a number of positive qualities:

- ecology,

- easy installation,

- durability,

- the possibility of creating any geometric forms,

- low weight, compared with stone,

- construction assembly rate

- easy dismantling,

- minimum improvement costs.

During operation, the owners of wooden garages face with other pleasant features of the material, which manifest themselves depending on the climatic features of the region:

- high paropropusk ability

- resistance to negative atmospheric influences,

- high waterproofing indicators

- rodent resistance,

- quality noise insulation.

Nevertheless, the tree is not perfect. Although the material is quite practical, it needs a certain processing with special protective agents. It is done to protect from:

- fire

- bacteria

- fungus

- mold

- wood insects,

- destructive action of ultraviolet

- temperature drops

- negative impact of moisture.

With the right approach to the choice and preparation of materials, wooden structures will serve significantly longer than any other counterparts. For example, in England and Germany there are residential buildings, which are already more than seven hundred years. They still live in them, and external appearance significantly exceeds its beauty modern buildings.

Wooden garages projects

The first step towards the construction of a wooden garage is its visualization. There are several types of this design:

- frame

- national team

- cut.

The log house is the most expensive, but most interesting option. Further distinguishes its following facts:

- aesthetic appearance, which is harmoniously combined not only with a wooden house, but also with any other buildings,

- construction monolithium, tight fit of wooden bars provides increased strength rates,

- resistance to mechanical damage to cut down, drill, or heat the wall so that the thief gets through the hole, takes at least 40-50 minutes,

- high mounting speed, from three to seven days, depending on the size.

The cost of such a design, taking into account the materials is from 8000 p. up to 40000 p. For 1 M. 2.

Wooden garages from a bar although good, but will require significant investment. Therefore, the national team is used more often. At the beginning there is a parallelepiped around the perimeter of the future garage, then the cheapest boards are sewn to it from two sides. Outside, they decorated with siding, internal work - at the discretion of the owner.

Cost from 4000 p. up to 10,000 p. For 1 M. 2.

A more advanced version of this technology is a wooden frame garage. It is distinguished by the fact that the parallelepiped is immediately built taking into account all the features of the design, including doors, garage doors, windows, etc. The design is performed in such a way that the frame of the frame reminds the chessboard. The cellular principle of internal overlap increases heat savings and significantly increases the strength of the structure.

Cost from 6000 p. up to 25000 p. For 1 M. 2.

Material overview

Before building a wooden garage, it is necessary to understand in detail in the varieties of wood, which is best suited for climatic conditions and the selected project.

1. Wooden timber. It happens like whole and glued.

- solid bars are made of a tree trunk. This determines the high cost of the material from 6000 p. 10000 p. per cubic meter. Another factor influencing the cost - type of treatment: profiled and unprofiled. Unprofiled products require further treatment at home. They have the raw surface, as a consequence, increases the consumption of paints, at least three times. In addition, during the fit and trim, unprofiled bars quite often give a crack, which then need to putty. Profiled embodiment does not have these shortcomings;

- glued laminated timber are divided into profiled and sheet. The manufacturing process of laminated veneer lumber is even more expensive. Therefore cubic conventional laminated veneer lumber cost 17,000 p, and sheet -. 36,000 p. Both options are glued together wooden webs. For the standard beam span width is from 2 to 5 cm, for sheet -. 0.5-0.7 cm With all the advantages of whole logs, glulam not subject to deformation, the geometry does not change and does not need additional support. However, the feasibility of its use for the construction of the garage, in the first place depends on the budget.

2. wooden board. The most common and inexpensive option - pine. However, this material is extremely moody, heavily exposed to mechanical stress, easy to absorb moisture and alter the geometry throughout the calendar year, which adversely affects the fixtures. The same disadvantages have fir and spruce. Among suitable for the construction of wood experts include:

- oak, perhaps the most durable and reliable material. Among the shortcomings - very poorly processed due to the high strength of the wood. Therefore sawing is better to order from the supplier. Price from 8000 p. per cubic meter;

- beech, convenient and practical. It has a nice natural color and is quite easy to handle. Price from 3000 p. per cubic meter;

- alder, the main advantage - high moisture resistance and the ability to simulate fine wood. Price from 2500 r. per cubic meter;

- larch for those who live in regions with abundant precipitation. The tree does not rot even under extreme constant moisture. The cost of 10,000 p. per cubic meter.

For most regions, ideal alder, but in northern and far eastern areas of better use of oak, which is more resistant to low temperatures and less fastidious in the care.

How to make a wooden garage of timber

Now consider in detail the steps that must be taken to build a garage from a solid or glued bar. Work plan:

- foundation arrangement

- installing floor

- construction of walls

- finishing work.

The monolithic foundation for wooden structures is needed only where the groundwater depth is less than 10 m. In all other cases, a sufficiently tape with a depth of 50 cm and 20 cm wide. For drainage, a gravel layer is 5-7 cm. Foundation height Earth must be at least 20 cm.

According to construction standards for a wooden garage, a pillars, in the extreme case, the pile foundation, but the absence of an obstacle around the perimeter in 99% of cases will lead to the appearance under the garage of mice or rats. Ribbon foundation will protect against such trouble.

The floor is filling directly on the foundation. Usually, a timber is used for these purposes, but a cutting board is suitable as a savings, with a thickness of at least 2 cm. It is set to lags, with a cross section 15x15 cm. Lugi is put perpendicular to the board. The distance between them should not exceed 0.5 m. Wooden beams are also recommended to strengthen the pouches. For these purposes, the trimming of beams, which are installed in a checkerboard manner on bricks. Perimeter square meter per meter. All mounts are performed by wood screws. To concrete and bricks, the tree is not attached, as a sufficient load is created under the weight of the walls for reliable fixation.

As soon as the basis is ready, go to the installation of the walls. And the whole and gluedboard, at the request of the customer, is cut into the supplier on the specified size. At the same time, it is necessary to draw a detailed plan of the garage indicating the size. Otherwise, the grooves on the logs will not coincide and will have to spend a lot of time for fitting.

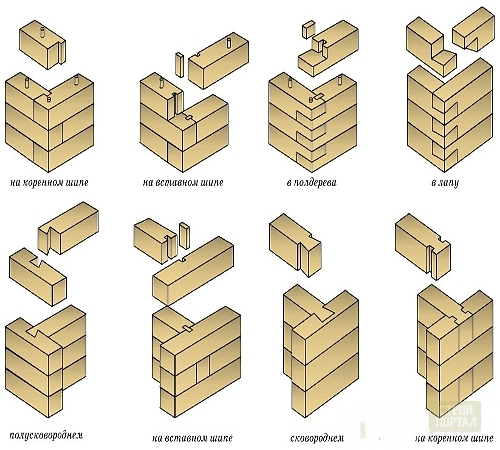

Since the methods of fastening logs with each other quite a lot, more clearly demonstrates the photo:

It is worth noting that the appearance of drafts in the corners. This is due to poor-quality grooves. Visually notice the defect is quite difficult, therefore it is recommended to use a thermal imager, clearly showing the temperature difference and the future wool bridge in winter.

Finishing works suggest the impregnation of the tree with the necessary impregnations and giving it a final appearance. The first part of the work makes sense even before the start of installation. Since all impregnations must be evenly distributed from all sides of the bar. As mandatory use:

- bacteriological, counteract mold, fungi and parasites,

- firefares, increase the temperature of the tree ignition 3-4 times,

- waterproofing, provide water-repellent properties.

Additionally apply:

- morlogs, change the color of wood,

- sunscreen impregnations, protect against burnout,

- structuring impregnations, adapt the structure of the fiber under the expensive breed.

The second part of the work implies the opening of the garage varnish. This is not necessarily, but the usual nitrocelulose matte coating will exclude the need for cosmetic work for the next 4-5 years.

How to make a frame wooden garage

Since the technology of the garage is a more upgraded version of the frame, consider both options together. Work plan:

- foundation arrangement

- carack assembly,

- insulation,

- cleaning.

In this case, the foundation must be made monolithic. The frame is easier than the bar, and this circumstance explains the fact that the wooden floor overlap will be quite difficult to fix. Naturally, it is often attached to the floor with the help of a dowel, but this method violates the integrity of the board, and significantly reduces its life. In addition, the monolith will simultaneously serve as a floor. If it is necessary to arrange the pit, then this nuance should be thought out before the foundation under the influence and install formwork in advance.

The frame is assembled as follows:

- there are beams with a cross section of 5x5 cm horizontally land, at a distance of 1 m from each other,

- the first corner beams are put, the remaining geometry is determined from them,

- to the floor beams are screwed with special metal corners,

- enough one on two sides, but it is recommended for reliability on each side,

- next, perpendicular to the support beams, the guides are attached, at a distance of 1 m from each other,

- guides need to be attached between carriers, so that nothing oppose the carrier beam.

Operactions under the doors and windows, if the frame was not ordered by the manufacturer, cut out after assembling the frame. The boards are cut into the amount of the opening plus 5 cm - the thickness of the beam for the window plus 10 cm, since the cutture will be needed from four sides.

For insulation, either foam or minvatu are used. Before their installation from the inside, steam barrier is tensioning. Next, the insulation is closed with steam barrier from the outside and the finishing layer of waterproofing. The cover of the finished frame is a matter of fantasy. It is siding, metal-turn, wood, plywood or any other material up to the gypsum.

Methods of finishing decoration depend on the material:

- for siding and metal - not required,

- for wood and plywood - varnish, simulator or their combination,

- for decorative stone - varnish,

- for natural stone - not required,

- for gypsum - special protective hardener.

Wood garage roof improvement

Whatever the type of the garage, the roof is always equipped in the same way:

- collecting a rafter box,

- fastened a fusion board,

- mounted insulation, vaporizolation and waterproofing,

- the outer coating is attached.

If you plan to use a soft tile, then before the last item, the roof rods are sewn with a slab, to which bitumen is already glued.

It is worth adding not so much about the roof assembly technology, how many ways to use it. Since the garage is traditionally considered a place for men, then the roof is preferably equipped either with a attic or an attic. At a minimum, this will allow you to add spaces to store various necessary things, from tools, to your favorite books and radio-controlled models. As a maximum, it is enough to simply equip a cozy room with an electric chain and a luxurious chair.