How to make a ledge for a well Useful advice

Own well and complete independence from external water supply - became the norm for most of the naughty and country sites.

Content

Drilling conducts many companies, however, rarely owner of the site and a company that led drilling is fully equipped well. After all, at the time of drilling there are not all materials and the necessary equipment for the complete arrangement of the well. And, as they say, the question is not in time.

When do you need a leap for a well?

The most correct answer to this question will be always! On the installation of the headband for the well, the owners often do not think. Although it is an important element of the system.

The headpoint primarily performs protective functions of the well: protects against ground and flood waters, contamination with various garbage, penetration of small animals, protects equipment from theft of thieves. Sealing the well on top of the head board will create a vacuum in the casing, which helps to increase the debit of well.

Designs Oglovkov

Wellheads are performed from various materials:

- plastic;

- cast iron;

- steel;

- aluminum.

According to the constructive type, divided into:

- headplains;

- sour covers.

Plastic and aluminum headings are used for shallow wells, where the weight of the equipment and water in the PND pipe can withstand the cover of the plastic head. The maximum weight for such systems should not exceed 200 kg. Cast iron and steel headings are applied in all other cases, they withstand weight up to 500 kg. This is quite enough for all household wells.

Handpoint for well

In most cases, it is cheaper and easier to buy a leg, but there are situations where it is impossible. Then you can make a well-headed headband.

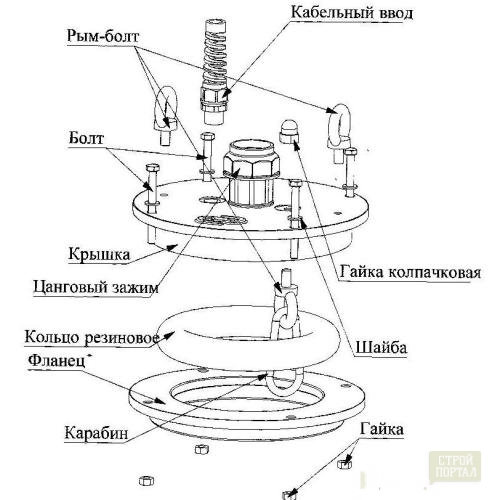

To do this, we need a flange, the inner diameter of which will be equal to the diameter of the casing + 2-3 mm. Flange weld to the casing. It also needs to drill 6 or 8 holes for connecting bolts. You can pull the structure and 4 bolts, but in this case, the sealing will be created in the best way.

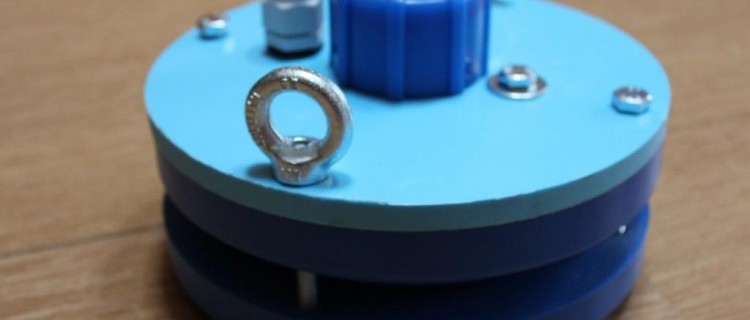

The lid will produce from a sheet metal with a thickness of 8-10 mm. In the lid, drill a hole for a power cable and a hole under the Tsanging cartridge of the PND tap pipe.

To the lid you need to weld or fasten 3 ry-bolts. One ry-bolt will "look" in the well - the pump cable is attached to it on the carbine. Two ry-bolts from above - for the convenience of raising the pump and well service. Holes for connecting bolts We also plan as well as on the flange welded to the casing.

For sealing we produce a rubber or paronite ring-gasket. The ring thickness should ensure reliable well sealing and be 3-10 mm.

A problem site for the installation of a homemade headband is the presence of welding. Or otherwise, buy a sealing ring. To install the factory head, welding works are not applied.

Installation of a well pump and headband

The casing must be trimmed strictly in the horizontal plane, clean and remove the bursavires, handle the location of the transmission of the primer, if necessary, paint the anti-corrosion paint.

Conduct the pumping of the pump according to the manufacturer's instructions. Attach the cable to the pump, the required length, the PND water pipe, and, if necessary, increase the power cable. Pipe, cable and pump power cable to pull the clamps after 1-1.5 m for the convenience of mounting. Stretch the PND pipe through the collet cartridge, the power cable through the cable entry. To the bottom flange to install a sealing gasket and pull the lid with bolts. Tighten the bolts evenly to avoid sowing the lid. After that, you need to pull the power cable and hold the cable input, the TNND tube is fixed.

Choosing a pump, should be taken into account if there is a well deviation from the vertical. Since practically all of the well pumps produced in China and in the CIS countries have a sliding centering bearing, which will break if the pump is installed at an angle. Foreign manufacturers, such as, for example, Grundfos, has modern models that are indifferent to the angle of inclination of the pump. The main requirement is that the engine is higher than the pump part.

The cable on which the pump is attached must be made of stainless steel or high-strength polymer. It is impossible to use the usual cable because it simply rusts and overtakes that threatens the pump's loss. Use special clamps for the cable.

Pump power cable will work under water. Use a submersible food cable. Depending on the power of the pump, the cable will have a different cross-section of the vein. Wire isolation is not afraid of moisture and works for several decades.

Hydrobacocco or hydroaccumulator is designed to collect a certain amount of water (depending on the tank of the hydrobook). When choosing a hydraulicock, it should be noted that in the labeling on the tank it is the full volume of the tank, and not the amount of water in it. Depending on the number of points, the volume of the hydroaccumulator is selected:

- 3-4 points - hydrobacion for 30 liters.

- 4-8 points - hydrobacion at 50-60 liters.

- More than 10 points - a 100 liter hydrobacom.

You can set several hydrobars in the system, since their total volume is summed up and no loss occurs.

Remember, the pressure pipe and equipment must be in the caisson or impressive. The depth of the pit is chosen below the depth of the primer of the soil in your region. For convenience, you can use warmed caisson. By installing the caisson, you also lose any problems associated with raising ground or flood water.