Plastic countertops for kitchen: characteristics, installation Interior items

Traditionally, in the kitchen, the hostess spend a lot of time, and it is one of the most visited places in the house. To improve the kitchen room, it is necessary to pick up suitable furniture and think over everything to the smallest detail - it is important to equip a comfortable and beautiful worktop serving as a working kitchen area. At present, inexpensive and easy-to-use products from chipsert or MDF lined with plastic are widely popular. Due to the successful combination of a durable surface, hygienicness, resistance to a variety of kitchen effects, plastic countertops have proven itself perfectly.

Content

Varieties of plastic countertops

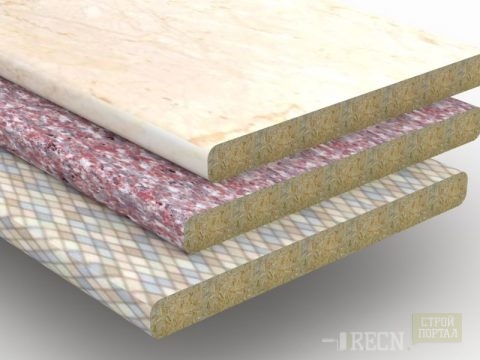

Kitchen countertops are special plates covering furniture stands on top and protruding as a working surface for kitchen work. As a basis of plastic countertops, as a rule, a profiled wood-chip plate (chipboard) is served, less often fibrillery (MDF). Plastic coating is applied to chipboard or MDF by the factory method, the base is coated with several layers of paper impregnated with a special composition, and treated at high temperatures under high or low pressure. As a result of this impact, paper turns into a dense monolithic coating. The resulting composite system has sufficiently good strength and water repellent characteristics necessary for kitchen countertops.

The HPL plastic coating (High Pressure Laminates) is made by point uniform processing on high pressure presses. This type of plastic is characterized by higher characteristics of strength and wear resistance compared to CPL plastic (Continuous PressED Laminates) obtained as a result of processing under the influence of low pressure. In addition, the quality of the plastic countertop depends on the base used (chipboard, MDF), as well as on the technology of facing plastic base.

Advantages of plastic countertops

With a fairly democratic price, plastic countertops for the kitchen have undoubted advantages - ease of operation and excellent combination capabilities. Due to the variety of products on sale, you can pick up a plastic countertop for a kitchen in any style. A durable sealing protective coating of plastic protects such countertops from swelling under the influence of moisture and allows them to use them as workers kitchen coatings over a long operational period.

The advantages of plastic countertops can also be attributed:

- fire resistance and heat resistance of plastic - plastic coating of the tabletop, if necessary, can withstand contact with a hot frying pan or pots;

- resistance to mechanical damage (cracks and scratches), as well as to abrasion;

- resistance to the effects of water vapor and aggressive chemicals, which is especially relevant in the cuisine;

- easy to care - a tabletop of plastic does not absorb kitchen pollution, it is easy to wash and clean it. Plastic coating does not need to care with special means;

- high color resilience - plastic countertops are not burnt under the influence of ultraviolet rays;

- a wide possibility of decorating kitchen premises through a variety of colors of plastic countertops. The HPL plastic coating is made in a variety of color schemes, including about 80 shades.

In addition, if you want to install the original product in your kitchen, you can coat the tabletop with plastic with any selected pattern. For this, various images used on the paper used in the manufacture of decorative countertops, various images are applied by printing.

Disadvantages of table tops with plastic coating

As deficiencies of plastic countertops, it is worth mentioning a less presentable appearance compared with natural stone products or glass.

On the plastic coating with evenly colored layers, the scratches are almost indistinguishable - nevertheless, if you do not use the cuts for cutting, imperceptible traces of a knife with time can swell and moisture will gradually penetrate inside the table top, which does not differ in the appearance of the product. Thus, the careful attitude to the plastic countertop will significantly extend its service life.

It is worth considering that even in the case of a high-rate made by the manufacturer of the high-level moisture resistance, which can reach 90%, it is not recommended to relax - in any case, in the process of mounting and inserting kitchen appliances, the joints of the countertops must be treated with silicone sealant, wax or paraffin, as well as with the help of seals and Edges. If the installation is made incorrectly either during operation, the plastic countertop is constantly exposed to wet air and water, the moisture can fall into the joints, which leads to the swelling of the chipboard - according to international standards, these phenomena is not a violation of the requirements for this type of material.

It is worth noting that, despite the above disadvantages, plastic countertops for the kitchen are widely demanded due to the successful quality ratio and price.

Useful advice

There is a wide selection of data from domestic products, as well as foreign manufacturers. You can buy plastic countertops in the form of plates with a thickness of 28 and 38 mm, length from 2 to 4 meters (standard dimensions of 620x3050 and 600x2240 mm), with untreated side and rear edges. As a kitchen surface, countertops covered with plastic low pressure CPL are the cheapest and affordable. Such a plastic coating is largely inferior in its operational characteristics (moisture and wear resistance) of high pressure HPL plastic. To distinguish on the external signs of the cut, a variety and quality of plastic is almost impossible.

To refer to the moisture resistance of the chipboard, manufacturers are added in the production of the green dye, which gives a cut product to the appropriate shade - its intensity does not depend on the degree of moisture resistance and in different batches of goods may be different. To choose a moisture-proof worktop based on chipboard or MDF, ask the seller about the availability of a certificate indicating the physico-technical characteristics of the material.

Plastic Countertops Design Choice

The surfaces of the Tumb and tables with plastic table tops are largely determined by the appearance of the kitchen room, so it is important to choose the actual design of these products.

When selecting a suitable color solution, plastic countertops should be repelled from the overall picture of the interior kitchen. In addition, you can use the following recommendations:

- the bright tones of kitchen surfaces personify cleanliness, so such a design looks quite fresh and stylish;

- saturated dark colors look spectacular. It should be borne in mind that there are noticeable on such countertops and stains and divorces from water are noted;

- tabletops with various original images and patterns are growing popularity. It is worth considering that such a drawing tabletop can "take a little" and over time to boring;

- furniture of various shades and textures will suit countertops with imitation of a stone surface;

- it is very natural and plausible plastic surfaces with a pattern that imitating wood of various breeds. Such countertops will harmoniously fit into the interior of the room in various styles.

How to install a plastic countertop for a kitchen

Sometimes the installation of such a product is included in its cost. Otherwise, to install a plastic countertop is quite actually with your own hands, before that it is recommended to carefully weigher than all "for" and "against" - perhaps it is still worth seeking help for professionals. If you need to cut the slabs for fitting for the necessary dimensions, you will need to have the skills of working with chipsert or MDF. It is worth considering that in case of appearance in places, cut cracks and chips, eliminate such disadvantages of the countertops in any way no longer work. On the other hand, a plastic countertop is distinguished by a low weight and comparative ease of processing for which simple tools and devices can be applied.

To install the table top, you will need to produce the following sequence of work:

- First, you will need to dismantle the old worktop, if there is such. Before performing measurements, the couches and lockers should be aligned with the help level horizontally - the table top should be installed strictly horizontally. Regulation by level is carried out with the help of adjustable furniture legs, or by using wedges and rubber gaskets.

- Next, it is necessary using a marker or a pencil to apply markup on the plastic plate according to the necessary dimensions, including the excavations and protrusions on the walls. For this, the tabletop is trying in accordance with the future placement location, leaving a 0.5 cm gap to the wall. The markup should be applied according to the dimensions of the countertops, taking into account the end slats (if it is planned to cut with the help of a hacksaw - from the front side of the table, if with the help of an electrolzik - on the reverse side of the plate). In addition, at the bottom of the countertops it is necessary to mark the place under the sink, circling the hole of the desired form around the perimeter of the sink with a pencil.

- After applying markup, it is necessary to carry out a cutting plate with a tree with a tree or an electric bike - more convenient to do this if you lead it along the guide plank. To eliminate the appearance of cracks and chips, it is recommended to pre-stick a greasy tape over the cutting line.

- To remove the irregularities, the ends must be processed using a file.

- Next, you will need to cut holes for the desired dimensions under kitchen devices. In several places, the contour planned under the sink should be drilled by a diameter of 1 cm, after that the electrolybiz is inserted into one of them and gradually cut the line of the desired form.

- Open sections and joints of the joints should be treated with silicone sealant.

- Next, you need to install a mixer for washing, as well as if necessary, consolidate the available wiring.

- The tabletop formed and prepared properly is placed on a permanent place and fixed with special fixtures on the ends of the lockers. If there is such a need, the joints of the sheets that make up the tabletop are connected using metal slats.

- Facial sections of the plates are closed with overlaid and fix them, plinths are installed in the right places between the wall apron and on the sides of the tabletop.

It should be noted that competent and high-quality installation is the key to the long service of the plastic countertop.

Plastic table top - Photo