Facade thermopanels. Characteristics of material and installation instructions Building materials

Facade thermopanels are an effective housing investment. With their help, you can reduce thermal losses and get a beautiful thin wall. The proper compound of building materials eliminates the formation of mold and dampness.

Content

Facade thermopanels (photos): Features

Depending on weather conditions and maintenance, thermopanels can be operated from 50-100 years. In the summer, they prevent the heating of the house, and in the winter they retain heat.

Facade thermopanels with tiles are a modern and most preferred construction option. This approach allows you to create good insulation, achieve architectural aesthetics at home.

Production of thermal fascus panels

Materials for creating thermal fascis plates are 2 components:

- clinker tile (protects the polyurethane foam basis from external influence);

- foamed polyurethane foam (performs the function of the base and insulation).

Clinker facade thermopanels are created in a plant in a special technology for the formation of a product in the matrix, which makes it possible to obtain high reliability and quality material.

Clinker tiles used in the production of plates data is obtained from the best clay varieties. It is subjected to burning up to 1200 ° C, which ensures the absence of cavities, complete sintering, strength and long service life.

Facade thermopanels: Properties

Thermofasid panels are diffusive, inert and durable material. The "dew point" is located in it within the volume of the insulation, which solves the problem of ventilation and sealing. In addition, the high-precision compound of the plates does not allow condensate, "cold bridges", and the groove and the comb, located on the sides, provide waterproof during the oblique rain.

The advantages of thermopanels

- Facade thermopanels, which can be used in a construction store, do not change the color, create good thermal insulation, do not appear.

- Thermopanels of the facade, the price of which is available, suggest easy installation in the shortest possible time.

- This building material does not require complex cleaning, special care.

- Does not absorb moisture, withstands various temperatures and weather conditions.

- It is environmentally friendly, durable, warm.

- Thermopanels facade act as insulation and finishing equipment.

- Provide optimal thermal insulation and aesthetics at home.

- Have light weight (from 15-17 kg).

- Can be installed on any surface - foam blocks, frame and wooden houses, aerated concrete, old brick, non-removable formwork, concrete slabs, hollow ceramic blocks, glass adhesive sheet, and the like.

- Fixing panels is carried out using a dowel.

Disadvantages of thermopanels

- Supplement surface preparation (alignment).

- May differ in quality (depending on the manufacturer).

- Are not a budget option.

Types of thermopades of facade

Today, the following types of thermopadals are distinguished:

1. Depending on the thickness of the insulation, which depends on the efficiency of the thermal insulation of the building:

- 40 mm;

- 60 mm;

- 80 mm;

- 100 mm (under the order).

In addition to this type, there are panels reinforced by a layer of OSP Plate.

2. By type of inner insulation.

As the inner layer of thermopanels may have:

- PPU (polyurethane foam) - universal high-quality building material;

- PPS (polystyrene foam) - such a type of panels can quickly collapse.

3. By invoice:

- facade thermopanels under the brick;

- thermopanels with glazed tiles;

- thermopanels with porcelain tiles;

- clinker thermofasid panels;

- thermal fascis plates imitating stone;

- thermal fascus panels under the tree (insulation is not used, created from the pressed tree).

4. By color:

- dark panels;

- yellow;

- having a classic brick colors;

- light.

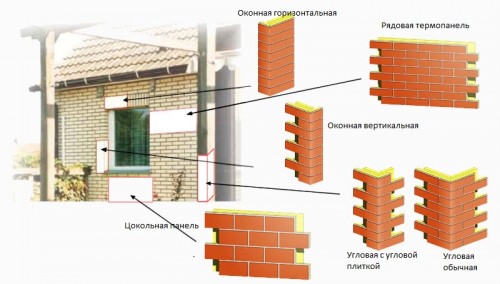

5. By sight.

Thermopanels are facade, the size of which depends on the purpose of building materials can be:

- ordinary (apply for wall cladding);

- angular (used for facing the corners);

- dobly (activated in case of insufficient material);

- codes (used for the design of the base level of the wall).

Installation of facade thermopanels

Since thermopanels make various structures and sizes, with insulation and without it, there are several methods for their fixation:

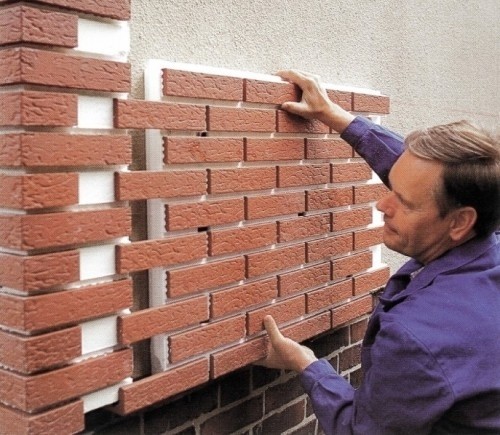

1. Directly on the wall with a dowel (if the stove with insulation is used).

2. On top of the foam with a dowel (if the insulation is not used).

3. On top of a wooden bar and foam plastic with screws (if the insulation does not apply).

This method is excellent for walls having an uneven surface.

Installation of thermal fascus panels with tiles

Tool:

- electrolovik;

- screwdriver;

- electric drill;

- circular with a diamond disk.

Progress:

1. Disable the horizon along the perimeter of the facade, check the diagonal of each wall. In the event that the deviation from the diagonal is up to 5 cm - eliminate the defect by creating gaskets from rigid moisture-resistant building materials. If more than 5 cm - we use the crate.

2. Along the base of the house with the help of a horizontal line, we mark the start of the finish. It has an aluminum base profile, which will subsequently serve as a launch rail and a tint. It is recommended to fix it 20 cm below the zero mark.

3. Installation of thermal fascus panels should be started from the left corner of the house. If the wall is a curve - vertical lighthouses are installed in places:

- cutting the edge of the thermopanel at an angle of 45 °;

- fix it at the angle of the building with the release for a short distance (with a support for a temporary mounting rail or the ground profile);

- mount the thermopanels bordering it from left to right;

- in the same sequence, we produce fixation of the elements of the upper row.

Next, create installation bottom up.

Do not forget to make a seal using polyurethane foam.

4. At the end of the installation of the panels, fill the seams between the tile with a special frost-resistant grout for facades.

Notes:

- when installing the base profile, leave the gap between it and the cabin;

- when mounting, without using the base profile, you need to create a temporary support device;

- after fixing the first horizontal range of the panels, the gap between the wall and the base profile should be filled with foam.

Thermopanel front video: