Machine for brick do it yourself Instruments

Brick is one of the oldest building materials. Carrier walls and foundations for buildings, partitions, fences, various buildings under the shopping needs, pillars and more are made. It is possible to produce brick in various ways. Throw this in more detail in this article.

Content

Varieties of material

According to the production technology and the composition of the material bricks are divided into:

- ceramic

- pressed

- silicate.

Ceramic brick is made of clay, which was formed in briquettes, after which the desired strength is attached by firing. This type of material is used most often, because it is suitable for almost any stage of construction. Such a brick can be both solid (otherwise full), and it may have technological holes that make it less weight. This material is often used to masonry furnaces and fireplaces.

For the manufacture of pressed bricks, special machines are used. After pressing, they are dried so that they acquire the necessary strength.

As for silicate bricks, they are made from a mixture of 8 parts of sand and one part of the lime. After pressing, they are treated in a special apparatus (autoclave), where they are under the action of a hot steam supplied under pressure. This processing gives the material necessary strength. Today, the most popular silicate brick M150 is becoming popular. Its dimensions allow to save on construction time. In addition, the laying solution is less spent with it.

Varieties of equipment for the production of brick

Bricks tend to make in factory conditions on special equipment. Nevertheless, there is a technology that allows you to make this building material from clay at home with your own hands. To do this, only a special brick press is needed. Its today can be purchased from specializing in such equipment companies. Although no one forbids to make such a press with their own hands. For this purpose, it will take quite a bit: a sufficient amount of material (it can be, for example, steel sheets) and a welding machine.

Before revealing the secrets of creating a homemade brick machine, we will tell about their structural elements. So, this unit is a press, equipped with a rotating base. Rotation occurs by the type of revolver. Based on the adopted forms in which a special mixture is supplied. While the base rotates, the material is pressed in one cell, and the mixture falls asleep in free molds. On the other hand, the installation gets the finished product. With the help of such a brick machine, you can quickly get a game of medium-sized products.

For making bricks, auger press is often used. In this equipment, almost all processes occur automatically. The housing of such a press is usually made of cast iron. In addition, there is a screw shaft and a supercharger in the design. To get a product, a clay mass must first be loaded. Moreover, it is important that it has a humidity of 19 to 24%. The output is a product in the form of a pressed bar. It is cut into several identical parts to get bricks. Sometimes the bar is not separated into parts, but use entirely as a separate building unit.

There is still special equipment for the manufacture of hypercasted bricks. This press allows you to compress raw materials as much as possible, resulting in a very durable brick. For this technology, hollow and full-scale (solid) blocks can be manufactured. The last of them are considered the most sought after.

The most different additions can be mixed in clay. As a rule, slag is most often added. But recently, when pressing bricks in clay, there were also components such as reed either straw. It makes production cheaper, bricks acquire some useful qualities.

Mix for the production of bricks

The production of clay bricks is based on the use of soils, which contain no more than 10-14% clay. The mixture is not suitable for the mixture and the vegetable layer. If skinny soil is used, clay is added to them. In addition, you need to pay attention to the moisture of the mixture. To check this, you need to take a handful of land and squeeze in a fist. In this case, the mixture should form a lump, not leaving traces on the hands. Bold soils are called those in which a lot of clay is contained. If they are used, then add additives in the form of sand, slag and ash.

If the lumps of land, rolled in the fist, do not disintegrate and do not smear, then this means that such a soil can be used. In order to increase the resistance to moisture and strength, the raw material is allowed to add 16-18% hydrate lime-puffs. Using the cement additive to a mass for making bricks, it is possible to increase the strength of the product almost three times. With such an additive, the mixture must be used for one hour.

Molds for the manufacture of bricks

Consider key components of such a form:

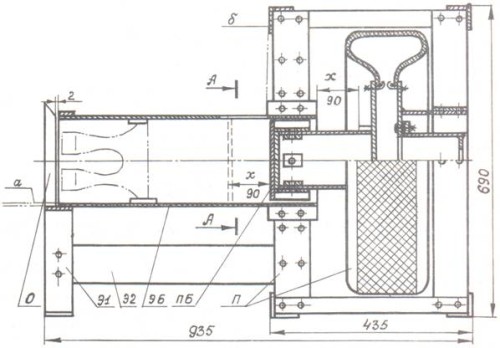

- The main element of the mold is the matrix (denoted as m). How she looks like? This is a fixed part in the form of a box without a lid and bottom.

- Another important part is Puinson (denoted as n). This is a movable bottom of the form that is controlled by the operator. It moves up and down. Puinson compression force is transmitted to the mixture. If the top cover is open, then the finished product, after the processing and pressing process is completed, is pushed out of the matrix.

- Also in the form there is a removable lid (referred to as K). This item covers the matrix from the upper side, while it can be fixed using the latch.

On the machine you can get bricks of various shapes and configurations. This is possible due to the change in the inner surface of the lid and punch. The quality of the products largely depends not only on the compression force, but also on the material, or rather the mixture from which they are pressed. High-quality solution makes it possible to get a brick whose strength is up to 40 kg / cm2.

Manual Machine

Professional machines are quite expensive in price. Not available and mixtures that are used to obtain finished products. To date, machines for making bricks at home are actively used. They are very in demand in the farm, especially when conducting construction work in a private house. Homemade installations are quite popular. To personally make a machine for making bricks, it is required to know the principle of its work, as well as that product with what characteristics you want to get as a result of pressing.

Today, the drawing of the machine for making a brick without problems can be drawn independently. Without the presence of a schematic sketch, it is not recommended for such work. It is worth saying that for the personnel making of such manual plants, it is not necessary to own the skills of the metal structural collector. However, in some cases you may need to help a qualified specialist. To make a homemade machine universal and multifunctional, it is enough to change the elements of the form for the manufacture of products. Then it will be possible to make brick at home different types and properties.

Machine for brick do it yourself

Bricks are easiest to make pressing method. To do this, make a special press. Materials will need iron sheets with a thickness of 3-9 mm. Of these, it is pre-cutting all the necessary parts to build a brick machine. The drawings in this will help.

From the tools, in addition to Pekala, you will need a drilling machine and welding equipment. Cut and make holes in iron sheets, you can contact the nearest workshop that is engaged in metal. Welding work is quite possible on its site.

The main loads during the operation of the machine will be on the press, which is made of a pair of sheets of 9-10 mm thick, sheet metal rolling. In total, the thickness of the pressing surface will be about 18-21 mm. This is quite enough to successfully use the machine in its intended purpose.

When all items are cut, they need to be welded with each other according to the drawings. In addition, it is necessary according to plan to collect moving parts of the future machine. When conducting welding, it is necessary to take into account the thickness of the metal. In particular, correctly select the size of the electrode. During work, do not forget to follow security rules.

Nuances of self-making bricks

To establish the release of bricks, you need to do the following:

- Purchase a set of special equipment (or make it yourself, according to the method described above).

- Examine the basics of the technological process.

- Prepare the necessary areas for the production that are suitable for them to be posted with all the most necessary: \u200b\u200bequipment, warehouse of raw materials and finished products.

- Matrixes, racks, pins, pallets are all parts of one equipment. If the machine for the manufacture of bricks is not constructed independently, and purchased in a specialized store, then a special console is provided to manage all processes. If there is no such thing, then all the stages of production will have to be monitored independently.

- The production process begins with loading the necessary components into the mixer. The homogeneous mass is fed to the ribbon conveyor, which moves it to the bunker. There is a unloading of the mixture in the matrix, where under the action of gravity created by vibration, its uniform distribution is performed. The final form of the product takes the pressure of the punch and vibration.

- Then finished products are shipped to pallets. After that, they are sent to passing chambers. They are gaining up to 35% of strength. The same properties can be given without a camera. Only in this case the product must lie within 24 hours at a temperature of +15 to +44 degrees. At a lower temperature for a set of strength, bricks will need two days. The maximum strength can be obtained only in 28 days at a constant temperature of +20 degrees.

- To speed up the manufacture of the product, it is placed in the chamber, where it is heated at about 8 hours at a temperature of +75 degrees. In such conditions, bricks will achieve their maximum strength much faster.

- The key step of production is the process of hyperpress. This technique, in turn, is based on the principle of cold welding. Due to the combination of such factors as high pressure, water and binder components, a sufficiently solid product is obtained.

- The main components of the mixture for the manufacture of brick are crushed limestone, cement and dyes. A lot of existing presss can only work with a raw material of a certain fraction.

- The strength of finished products depends on what power of the compression has a machine. The best installations can create pressure up to 300 tons. For comparison, most of the manual presses have this indicator 2, a maximum of 3 tons. Therefore, we can conclude that the most important factor in the manufacture of high quality brick is the used model of the press.