Interior decoration of fibrolite plates with their own hands Construction,Building materials

Today, fibrolite plates have gained great popularity in the building materials market. By itself, this material can be called universal. Plates are used for inner wall cladding and floor. The composition of the fibrolite contains various components (wood wool, cement or magnesite fibrololite). Depending on its composition, it is divided into species. Read more about the use of fibrolite plates - further in the article.

Content

Features and properties of fibrolite plates

- As mentioned above, the fibrolite is a universal material used in various industries of repair and construction. In addition to facing the floor and walls, it is successfully used to install internal partitions, overlapping the roof, as well as for mounting the formwork.

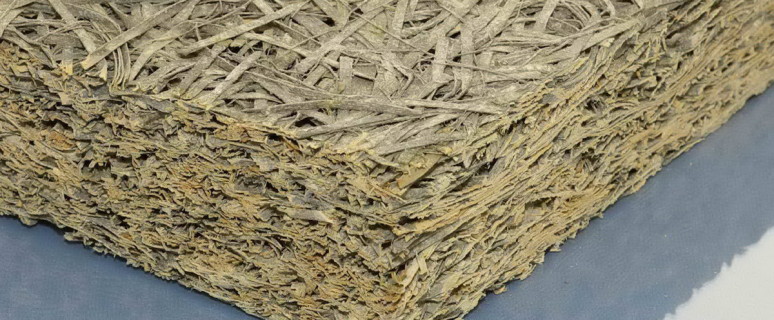

- The dimensions of fibrolite slabs can be different, depending on where they will be applied. The composition contains wood wool, which is a rather dense belt-like thread, the length of which varies from 20 to 55 cm.

- Fibrolite plates have many positive qualities, thanks to which they are increasingly and more often today used in the field of repair and construction. They are valued for their reliability, strength, durability, good performance properties. In European countries, houses from fibrolite plates, built in the last century, are still kept in good condition.

- The fact that fibrolite plates on Portland cement have excellent characteristics, testify the test results conducted by Italian masters. They confirmed that the material keeps the form under various weather conditions, not deformed. This is achieved due to the strong structure of wood threads and special silicates contained in the cooker. In addition, all components are processed by special mineralizing means that protect material from any chemical impact. Over time, as a result of the carbonization process, the characteristics of the material are improved, due to which it remains durable and reliable many years.

Mass distribution in Russia material received in the late 1930s. Since that time, the number of workshops and workshops engaged in the production of fibrolite plates for the floor, only increased. Today, as mentioned above, fibrololite is applied not only for cladding floor and walls, but also for mounting the formwork in frame-concrete and monolithic construction.

Types of fibrolite [plates

According to the current Guestbags No. 8928-81, the dependence on the thermal insulation properties of the Fiberit is classified into the following types:

- F-300 is insulating with thermal insulation properties,

- F-400 - construction and insulating fibrololite,

- F-500 - acoustic fibrololite.

According to the density and strength, the material is divided into the following types:

- GB1 - low-density fibrololite,

- GB2 - Material with average density indicators,

- GB3 - material with high density indicators,

- GB4 - Combined Fibrololite (layer) - Low and high density layers alternate in these plates,

- GB1L - material with minimal density indicators, used for heat and sound insulation,

- GB3F - Combined Fibrololite, in addition to high density indicators, it has a special decorative coating.

Fibrolite plates for finishing have many advantages, among which fire resistance, wear resistance, strength, resistance to mechanical damage (injuries from insects or small rodents). The material is considered a good heat insulator and soundproofer. That is why fibrololite today is very often used for indoor facing in residential buildings. However, this will require a minimum density material.

Installation of fibrolite slabs is necessary when installing basement and non-removable formwork. The use of such material makes it possible to reduce the estimation of construction work by almost 60%. Strong fibrolite plates of the GB3 class are used in the construction of frame buildings as external walls or interior partitions. At the same time, they are shed a wooden or metal frame.

Class F-500 plates are used as a sound insulator when arranging staircases, lobby. And if the fibrolite is additionally covered with decorative finish made of roofing fiber, it is quite possible to use wooden buildings for facing the roofs.

In a separate category, you can select Greenboard plates. This subclass of Fibrolite has absorbed all the best properties of the material, among which:

- Good thermal insulation.

- Excellent soundproof properties.

- High strength.

- Frost resistance.

- Good thermo- and hydrauliculation.

- Fire resistance (material class g1).

- Waterproofing (the material does not lose its properties and shapes when moisture in it).

Given all the characteristics of the material, you can not be afraid to mount hidden wiring in fibrolite plates. In addition, this material can be successfully combined with other types of facing coatings.

As part of Greenboard slabs contains threads of wood wool (more than 55%). Thanks to this fact, they act as a "battery" moisture. When interacting with wet air, excess moisture penetrates deep inside the structure of the plate, where it accumulates. If the air indoors becomes too dry, the stove gives moisture back. Due to this, the optimal level of humidity can be maintained in the room. Unlike other materials, such as wood, fibrolite plates do not change their dimensions due to a change in temperature and humidity, which makes them an excellent finishing and building material.

Among the shortcomings of fibrolite slabs, it is possible to distinguish them relatively high weight. If you compare them with a tree, then they are heavier by about 15-20%, but in comparison with concrete they are much easier.

The popularity of the use of GreenBoard plates has recently increased several times. This material is considered the most promising for external and interior decoration, as well as for the construction of frame houses. It is very often used for making formwork.

Such popularity is explained by the excellent functional characteristics of the material and ease of installation. In low-rise frame construction, fibrolite plates can be an excellent alternative to OSB. Through the use of wood waste in production, the cost of such a material is competitive. The price of the plate depends on its density.

The procedure for mounting fibrolite plates

The process of installing fibrolite slabs depends on the scope of their application. When building a building with this material, the process of its installation resembles the installation of polystyrene panels.

- First, the remains of plaster and possible pollution places are removed from the surface of the outer wall of the building. The fibrolite stove is glued to the surface of the wall using a special glue. It is for sale in the form of a dry mix, which must be dissolved for use with water. The consistency of the finished solution should not be too liquid. Otherwise, the stove will slide under its weight. When preparing a solution, it is necessary to take into account the speed of laying the material. If it is low, due to a small experience, it is better to knead a small amount of glue. The fact is that it is quite quickly grasped, and after the frozen, it is strictly forbidden to use it. Working with "small portions" will reduce the consumption of material.

- Stacking fibrolite plates with external warming of the facade is carried out from below. At the same time, rows, like brickwork, should go with overlapping. Simple words: the middle of the top row plates should be at the joint level of the two plates of the previous one.

- When laying, the glue solution is applied with a solid level both on the wall and on the back surface of the plate. For applying glue, a special spatula with a served end is used.

- After laying the plates, they are additionally fixed with special dowels. They have the shape of an umbrella. Thanks to the big head, such dowels reliably hold the stove. For each one you need 5 dowels. One is installed in the center, the rest in the corners. The length of the fastener depends on the thickness of the plate. Inside the wall, it should go no less than 50 mm.

- After the plates are installed, they can be laid down. Plaster protects the fibrololite from the effects of ultraviolet and, especially moisture.

- A reinforcing grid is applied to the surface of the slabs before applying plaster. It is simply glued to the surface with glue, which is rubbed by a spatula. Then, after drying the adhesive, the layer of plaster is applied, which rubs and ground. After the primer dries, paint is applied to its surface for outdoor facade works.

- When building a skeleton house, fibrolite plates are attached directly to the framework of the building. Moreover, they are installed both outside and from the inside. Between them, inside can be put a layer of mineral wool, which will make the structure warmer.

- From above, the plates can be covered with siding, thereby protecting them from moisture, or to launch and paint. Recently, the finishing of the external walls is popular with tiles, which mimics the brick. It has an excellent appearance, performance characteristics, serves quite a long time. However, this type of finishing is very laborious and worth a lot.

- With the internal finishing of the room, the surface of fibrolite plates is plastering or sewed with plasterboard.