How to set up a chainsaw Instruments

Chainsaw is a tool needed in the farm, without which it is impossible to quickly and efficiently perform some economic work. Like any complex mechanism, chainsaw requires high-quality and timely maintenance and configuration. Most often, the carburetor is needed for good work, but there are also some rules of operation that should be followed.

Content

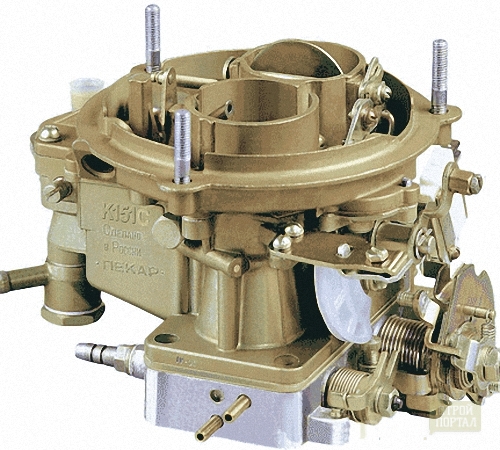

Chainsaw carburetor device

To understand how to properly configure chainsaw, you need to know the nuances of the device of its main nodes, in particular the carburetor.

1. It works on the same principle as the internal combustion engines - the mixture is burned in the cylinder, provoking a small explosion. The pressure from the explosion pushes the piston, and he, in turn, rotates the crankshaft. The movement goes at the time of rotation, it moves the chain through an asterisk. The motor with optimal work consumes in each cycle to 10 mg of fuel. The mixture for the engine is prepared in the carburetor.

2. The purpose of the carburetor is to prepare a mixture of fuel and air in the desired ratio. If the device prepares it with violations in proportions, then the functioning of the engine itself is disturbed. Improper mixture is called poor or oversaturated. In the poor mixture, the amount of oxygen in relation to fuel is increased, in the oversaturated - on the contrary. In both cases, failed mechanisms that require elimination begins.

3. The main design and principle of the functioning of the carburetor have a common base, but differ, depending on the chainsaw model. For example, if you need to configure Chinese chainsaws, you should familiarize yourself with its service book and the structure of the device. In general, the work of the carburetor and its basic elements are as follows:

- the base is a tube, the functional properties are similar to aerodynamic. Through this element comes the air flow. It is crossed by an air damper, which blows the cavity or opens, the amount of incoming air or decreases;

- the diffuser is based on - increases the air flow rate in the hole allotted for the stroke;

- sprayer - a fuel through it falls into the air flow. In the sprayer, the fuel passes through the jaw from the float chamber;

- the float chamber is a container for retention of the mixture at a stable level.

The general principle of the functioning of the carburetor:

- The fast air flow goes through the channel, the valve adjusts the speed of this thread.

- Opening a channel adjusts the position of the float.

- Through the diffuser goes the air flow, mixing with the incoming flammable and spraying it.

- The resulting mixture enters the cylinder through the inlet pipeline.

The pressure indicator in the float chamber is close to the atmospheric, in the air canal this indicator is rare. The difference in the indicators provides suction of fuel through the jaw in the air canal. The larger opening of the air damper leads to the admission of larger air, and therefore, to greater fuel flow. An increase in incoming fuel leads to an increase in engine speed. The principle of action of the simplest carburetor is described. Having learned the foundations of its device, it is easier to understand and determine the purpose of the remaining elements.

Signs of the need to adjust the carburetor

Necessary in the adjustment of the carburetor chainsaws occurs not often. The inclusion is determined by the following features:

- Unstable motor work: hardly starts to start and immediately stalls, it does not start at all. The root cause is the use of low octane fuel mixture.

- Fuel reserves, abnormal consumption. Exhaust exhausts are allocated above the norm. Fuel is not fully consumed. The reason is the use of a gluable mixture.

- Violation of the fastening of regulating screws due to fluctuations or faults of the protective cap coating. Unique, rarely encountered breakage. The cause of the failure is touching the screws, an attempt to unwind or adjust the node.

- Significant wear piston. Adjustment will move the repair only for a while. Requires engine overhaul.

- Cutting carburetor. The reason is the use of low-quality fuel, air filter malfunction, scale falling. Adjustment should be carried out simultaneously with washing.

How to set up a chainsaw partner

You need a screwdriver screwdriver to work.

The adjustment of the carburetor is carried out independently when the tachometer and the ability to work with it. Otherwise, independent work is meaningless, the adjustment of chainsaws should be entrusted to professionals-mechanics.

Adjusting the carburetor chainsaws is carried out by only one screw, the other two are hidden from the consumer by the manufacturer. The designation of them on the case is:

- L - to configure low revolutions;

- H - to configure high revs;

- T - Visible Screw user. Adjusting idling.

The manufacturer's plant regulates the functioning of the carburetor under the optimal mode, leaving the possibility of adjusting the node adjustment in extreme situations. When using the apparatus in the recommended ranges of temperature and air composition, it is not necessary to study.

To adjust the work, applying fuel that differs in quality from the standard, the screws L and N. are used to reduce the octane number of gasoline, the screws rotate from left to right. This will increase the number of revolutions. To increase the octane number, a turn on the right is performed. Low revolutions are exhibited.

Adjusting the carburetor chainsaw partner or other manufacturers is carried out with the following rules:

- Conduct accurate works only on the hot engine. The minimum working time is 10 minutes.

- The air filter should be not clogged and clean.

- The rotating circuit stops using the adjusting screw to complete braking. The screw turn right left.

- Compliance with TB rules. Direct the chain in the opposite side. Install the saw on a smooth surface. Do not touch the cutting part to the subjects.

The exact adjustment of the screws is in such a sequence: L - N - T. screw L is the maximum number of revolutions by turning it from left to right or in the opposite direction, until the maximum is reached. In this process, you will need a tachometer or a good hearing of the wizard, which determines the limit revolutions. If it is incorrectly determined by the PC regulator, the engine will break. The cost of repair will cost more than half the total cost of chainsaws.

When using a tachometer and absolute confidence in determining the limit revolutions on the sound of the motor, adjustment is brought to completion. The regulator L is the maximum or close to the maximum value of revolutions. By the same regulator we return to the right to left by a quarter of the screw turnover. We perform the same action by the controller H: turn it on a quarter of the screw turn on the right left on the heated engine. We determine the sound - the motor is spinning at a maximum as a four-stroke mechanism. With a rich mixture, a squeal appears, which is removed by the screw, selects the average sound of the operating engine.

Adjusted idle. The screw is rotated counterclockwise until the chain stops. If it is not possible to independently adjust the idle move, you need to contact the master. Work on non-adjusted chainsaw leads to man injuries.

With a customized carburetor:

- At idle the chain does not move.

- Fast motor acceleration.

- The sound of the working motor is consonant with the operation of the four-stroke apparatus.

How to set up a chainsaw, video illuminates this process in detail:

Common causes of breakdown chainsaws

The breakdown of chainsaws often happens due to the violation of the rules for using the tool:

- Not knowledge of rules. Not exact following instructions. Not reading important instructional instruments.

- Inaccurate instructions for the tool. This item is possible when buying a cheap tool is not factory assembly.

- Unexpected inspection of the chain and nodes. After performing a large amount of complex work, the tool is necessarily inspecting, the parts are lubricated, the integrity of the chain is checked, its work at idle.

- Tool overload. It is necessary to withstand the rules of operation. Give the tool "Rest" recommended in the serviceport.

- The use of chainsaws are not functionality. Operation for cutting or cutting materials not provided in those passport.

- Refueling by low-quality fuel. The use of old gasoline from its own stock, incorrectly or long-prepared fuel mixture. The octane number decreases within a month by 10% - 15%. In mixtures with oil, there is an additional oxidation of gasoline and turning it into fuel oil or its derivatives. Dirty gasoline is destroyed for the piston system. Chainsaw is very sensitive to the quality of fuel and quality of oil. The owner must follow the compilation of the mixture, use the recommended fuel and oil, stick to a strictly installed mixing proportion.

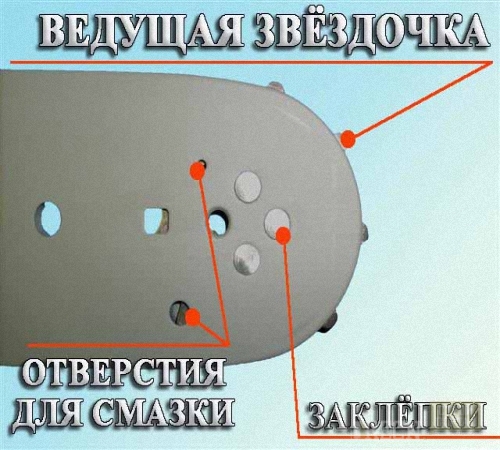

Proper lubrication of the saw tire

The proprietary tire lubrication procedure and the tool chain procedure is made by specialized oil and composition. A list of contraindications to the use of other varieties of oils is given to avoid breakage of the oil pump. Practice shows another picture. Most chainsaw operators are used for lubrication cheap ordinary oil. This is allowed under the condition of its freshness and purity. Operating, poured into the tank, even filtered, clogs filters and oil pump.

Basic Terms of Use of Oil:

- It is necessary to monitor the oil level in the tank.

- Do not run a motor with an empty tank.

- Pour winter oil when working in the cold.

- For winter time, use the usual oil grade divorced with kerosene in proportion 4: 1.

- For minus temperature, set the flow at the maximum position.

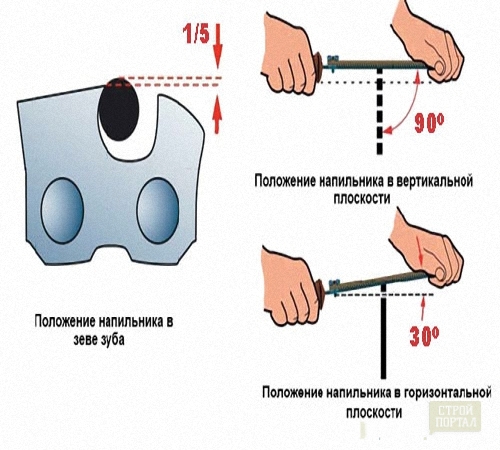

Sharpening and using saw chain

To reduce the load on moving elements and renewing the chainsaw work resource, the chain sharpening is carried out. When sharpening, avoid mechanical methods. They lead to a decrease in the life of 2 times. Enjoy it is recommended for templates and files designed for chainsaw. Handling with special templates simply, does not require dismantling the chain from the tire.

Filters chainsaws

Air filter Chainsaws carries a large cleaning load. After the next work cycle, it is recommended to remove, clean and flush the nylon mesh filter. For washing, use a soap solution without foam, rinse in running water and dried on a draft.

Air filter from the foam rubber rinse in kerosene, squeeze, dry. The edges are lubricating, for example, Lithol-24. Velvet filter mesh rinse in simple warm water without detergent. The filter replacement is to be replaced in a timely manner, install a new absorber of the same type and size, which is spent.

Candles of ignition chainsaws

The replacement of candles must be made after the status recommended date. Use only original factory details. Incorrect or untimely replacement of this node often becomes a cause of chainsaw. Workshops in this situation are refused to perform warranty repairs.

Getting started with a new chainsaw

Use no adjustment 15-20 refills. In a new tool, the manufacturer provides for the supply of fuel in the enriched form to work on medium turnover. This excludes exceeding the maximum load, increases the crankshaft lubrication, piston group and bearing.

- Dry running at idle and at maximum loads do not produce new tools.

- Do not exploit the device for full gas. Do not put pressure with excessive effort.

- Do not bring the tool before overheating.

- At the end of the recommended period, you should configure chainsaws in the workshop.