How to make the installation of facade panels do it yourself Walls,Construction

The facade is important to properly maintain, the Veds depends not only by the appearance, but also the general condition of the house. The correctly separated facade allows to avoid heat losses, the influence of negative environmental factors and increases the service life of materials from which walls are built.

Content

We choose the finishing material

The finish of the house with the front panels should begin with the selection of the type of these panels. To date, there are the following types:

- metal siding,

- siding using decorative tiles,

- wooden siding

- PVC Siding,

- siding under the stucco.

Each of the materials has its pros and cons, in addition, the installation technology is significantly different in each of the options.

Professor for metallic siding is made of high-quality steel, which is resistant to any types of corrosion. Special protective coating on the facade makes the burnout of the colors at all. Without visible changes, such a coating can serve at least 10 years. The minus is just that professional flooring weighs quite a lot, therefore it creates a serious additional load on the bearing walls. It is usually used for garages or single-storey handles.

Siding using decorative tiles is a new word in the market. Such facade panels for home consist of the base (most often extruded foam) and an external decorative layer. The material simultaneously serves as insulation and imitation of expensive facade stones (coroede, lamb, etc.). From the flaws only the price.

Wood siding, as well as heavier metallic construction, however applicable to single-storey buildings or decorating the first floor. Although the material and processed at the plant with special impregnation, minimal maintenance is needed after a 2-4 season. With proper treatment will last virtually forever.

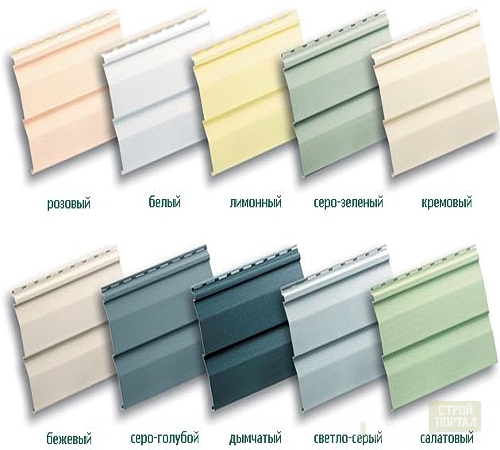

The easiest and cheapest option - polymer facade panels. They are easiest to install, durable enough, do not interact with the environment and can be easily replaced in the event of mechanical damage. Lineup is rich and allows you to find almost any design solution. Minus - the aesthetic aspect. Upon closer contact it will be seen that the house is sheathed with plastic. Used for the improvement of cottages.

Front panels plaster - this is a controversial name for products made of molded foam. Material is the perfect insulation, does not create an additional burden on the walls and allows them to "breathe. Of the minuses - highly susceptible to mechanical damage. Complete replacement of such a panel would require major repairs of the building.

Installation of metal siding

Decorating the house exterior façade panels made of profiled steel - it is quite an easy process. For it will need the following tools:

- bulgarian or tin snips,

- pliers,

- screwdriver (cross),

- screwdriver,

- screws for metal

- dowels or anchors (depending on the wall material).

Installation takes place according to the scheme:

- obmeryat wall of the house,

- draw a skeleton figure,

- fix the frame on the wall,

- install insulation,

- fasten sheets.

Measurements are made in order to mathematically calculate the correct amount of the desired profile, and drawing allows to visually see the location of the frame, and, if necessary, to edit it down on paper.

Mounting frame is performed as follows:

- fix the first profile perpendicular to the ground,

- at 30 (50) cm - the second, and so on to the end walls,

- the carrier profile is fixed by dowels or anchors

- prepare transverse bulkheads at both sides to make incisions and fold them in such a way as to obtain a "foot" (if the distance between the bearing bulkheads 30 cm, transverse bulkheads should be 40 cm to 5 cm from the edges of the incisions made for the "legs"),

- consolidate the transverse bulkheads (not bolted to the wall, and a supporting profile).

Alternatively, you can purchase a more expensive ready-made system for fastening metal siding, but it is attached directly to the wall of the house. Buildings from silicate, red brick or foam concrete is not intended for such structures, since from abundance of holes there is a risk that the stones burst.

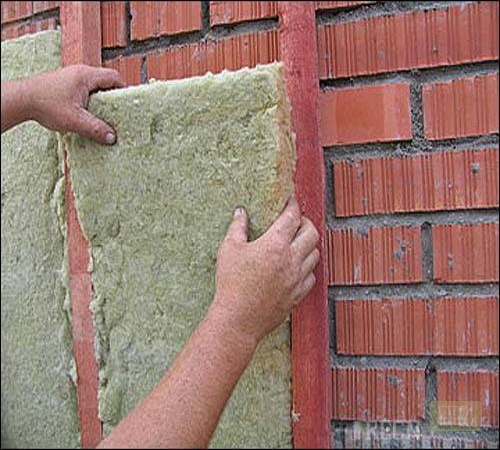

In the resulting squares are installed insulation:

- mineral wool,

- styrofoam.

After that, siding "is sewd" to the frame. Profile sheets have a special hidden seam, which allows you to hide the screws and makes the design of the monolithic.

Another installation option is a narrow metal siding. For it, they use a special system that resembles a suspended ceiling. After installing and insulation of the frame, the narrow metal panels are inserted into the formed openings, the mount occurs according to the "lock" principle.

Installation of saidding panels using decorative tiles

Facing with facade panels with a decorative element is the fastest and most reliable version of the siding. Such panels have special grooves that allow you to tightly fix two adjacent sheets, the seam is not visible.

They are mounted on the construction glue. No preparatory work is required. When buying this material, it is recommended to clarify the seller also the name of the adhesive mixture. The glue manufacturer will indicate the proportion container in which the solution is made. Use a toothama to apply glue.

The secret of high-quality gluing is simple enough - after you put a sheet to the wall, hold it for 2-3 minutes and take off, after 2 minutes of the stamp again. This procedure allows you to make a more chain compound of materials and increases the strength of the structure. In addition, if with a re-attracting sheet to the wall, it falls off, it means the glue is not suitable or you used it too little.

Installation is better from bottom-up in the rows. This will save the pattern (if there is a picture) and allows you to use the bottom layer as the support for the upper one. Before installing the next row, it is necessary to wait from 15 to 30 minutes (the minimum time for gluing is 1 hour, the process is completely completed). It is best to perform work at a temperature of +15 to +25 degrees Celsius.

The same rules also apply to the installation of siding under the plaster.

Montage of wooden siding

As in the case of a metal analogue, there are two solutions:

- wrap on alone

- purchase ready-made design.

For the wallboard, the same frame is going as for the professional flooring. But as materials here, you can use a tree. Wooden beams are treated with antiseptics and mourn. As a result, the boards are protected from atmospheric phenomena. Tip: Do not put the beams directly to the ground, make small substrates, otherwise the wood will nourish moisture from the soil and starts rot.

The advantage of this option is that the lining will simply be just glued to the frame. Do not forget the space between the wall at home and the clap fill in the insulation.

The finished design is the same version of the suspended ceiling with a block system, but it is not done in a checker order, but consists of guides. Mounted as follows:

- edge guides are installed,

- then the internal (at a distance equal to the length of the wooden board),

- there are panels between the guides,

- when the first strip is ready, go to the second,

- at the end, the top row is written and covers the locking plate.

Minuses:

- lack of insulation

- bad sound insulation.

Another kind of wooden siding is long-axis lining. With it, any facade is cut without any frames. Long stripes up to 6 meters. It is attached to the wall with liquid nails, or on a dowel, or on ordinary nails, depending on the material of the wall. Considering the length of the canvas, work must be performed together.

PVC siding

Facade polymer panels are mounted either on the frame, or with a gun for a bracket. The framework installation procedure in several versions was described above, and the installation with the help of the bracket will consider in more detail. For this type of siding is the optimal solution.

Fastening the front panels on the staples is possible only to the monolithic wooden surface. Therefore, it is used in frame construction, or with American build household technology. Specially sewing the walls of the OSB or the chipboard does not mean. This is quite expensive and does not contribute to the increase in thermal insulation. Alternatively, brackets are replaced with liquid nails.