How to choose an edge banding machine Instruments

One of the most complex technical devices that are used in furniture production is an edge-boundary machine (easier - edge). It faces the straight or curvilinear edge of the furniture billet, giving an aesthetic appearance to the finished element, and protecting it from bundle and mechanical damage.

Content

To pay attention to when choosing a edge

The edge can be glued, feeding the workpiece manually or automatically (semi-automatic), synthetic or natural material. Automatic mode is used in large factories where a large flow of work is performed. But the manual edge banding machine has a big advantage over the automatic fact that it is more accurately produced by the harvesting of a complex shape or figure. Usually owners of furniture factories acquire the machines of both types.

Buying edgebanding equipment, especially if you are a novice furniture maker, you need to consider several nuances.

- You need to know exactly how the edges of the edge meters per day you will be glued. What kind of the surface of the surface is taken. What thickness has the edge with which you will work.

- Do not look at the price, there is more expensive or cheaper there, and check carefully and compare the characteristics: weight and power, the presence of all units, and not universal nodes that combine several functions at once. Pay attention to the size of the aggregates and its component parts: the diameter of the guide, the cross-section of the bracket, the dimensions of the aspiration bottle. Be sure to be present, the automated rotation of the saw in the targeting node and placement of the node, which presses the edge and milling devices. And the centralized automatic lubrication mechanism of parts and the dosage of glue with the adjustment function from the operator's console. Of course, oscillations should be present in polishing and individual maneuvering by the lower and upper mechanism.

- When buying a edgebanding machine, think about the fact that there are many condensate and dirt in the air and therefore pneumatics can quickly fail. In order for the air to have the desired condition, use a screw compressor, which has refrigerated drainage and is equipped with efficient filters. The performance of the aspirational installation must be within 2500-400 m 3 per hour, and the vacuum created in this case is about 2200-2400 pa.

- Buy a machine that has several units with special tools separately for material with a thick and thin edge. And also to allow you to automate configure the parameters of the removable allowance. It is desirable that the correction of the angles is made both in the transverse and longitudinal orientation.

To help you, it is better to figure out which edge-binding machine to choose to consider several models that are sold in the modern market of woodworking equipment.

Edge banding machine brandt.

Stroof edgebanding machines Brandt designed for the shape of the edge to the rectilinear ends of the furniture billet. The glue is applied with a special roller, and pressed with rotating cylinders. You can set the machine at will and other options.

This German firm produces several series and models of edge-binding machines.

AMBITION 1100 series is one-sided machines that glue the edge with a thickness of 0.4-2 mm to a billet with a thickness of 10 to 50 mm at a speed of 6 m per minute.

The AMBITION 1200 series machines are equipped with a solid bed for fitting aggregate techniques. The machine has a length of 3.5 m and a height of 0.9 m. The edge of a thickness of 70 - 120 mm is supplied at a speed of 11 m per minute and is glued to the workpiece with a thickness of 8-50 mm.

BRANDT also has models from the AMBITION 1400, 1600 and 1800 series. They differ from each other in that the higher the serial number, the greater the parameters of the machines.

Edge-banding machine Felder.

Felder provides its customers with edge-binding machines of different categories:

- Universal,

- Professionally,

- Premium

- Mobile.

Universal series machines (Forka 300 S Eco; New G 320; G 330 and G 460) have the following properties: are small, work with a roll edge of 0.4-3 mm for furniture blanks with a thickness of 10-45 mm. Suitable for glue edges to straight or curved blanks.

Edge-binding machines professionally (G 500; NEW G 660; New G 670; New G 680) These are multifunctional units that are designed for fugging, rounding angles, cycling and polishing billets at a professional level. It works with a rolled edge material with a thickness of 0.4-3 mm from wood 0.4-5 mm for billets 8 -60 mm.

PERFECT 608 X -Motion Plus (Perfect 608 x -motion Plus; Perfect 710 x -motion; Perfect 710 X -Motion Plus; Perfect 710 E -Motion; New Perfect 812 x -motion Plus; New Perfect 812 E -Motion) This high-performance professional equipment. The result of the operation of these machines is maximally accurate, and the glue seam is practically not visible.

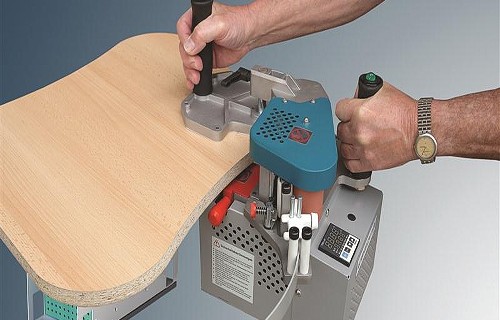

Edge-binding machine series Mobile - Felder Forka 200 is a small, convenient, flexible, hand tool for stationary and mobile application. It is used more often for auxiliary or repair work.

Edge banding machine griggio.

The Italian company GRIGGIO founded in 1946 produces woodworking equipment of different types. Among them and edge-knitting machines GB, manual and automatic, which glue straight edges from natural wood and laminate, PVC, and ABS.

Of all the models of this company, the GB M manual machine is the most small (weighs 8.4 kg) and easy to control. It is used in mobile and inpatient form for cladding parts edge up to 3 mm and maximum thickness of the billet 45 mm at a speed of 1-4 m / min. The machine has an adjustment of the temperature mode and speed variator.

The remaining models of Griggio edge-binding machines differ from each other by dimensional sizes, weighing and power. This is a highly professional equipment, which is basically a glass with a thickness of 0.4-8 mm for furniture parts with a height of 10-60 mm, at a speed of 1 to 17 m / min.

SCM Olimpic Edgeband

Judging by the reviews of users, the edge-bounding machines of the Italian company founder of the SCM Group, which includes several trademarks, are inconvenient to use and do not cost paid money. They are difficult to configure due to the lack of the rear folding cover. Have a small glue and short-lived shoe copiers.

Cechisa edge-banding machine

Cehisa was founded in Spain in 1956, and is actively developing in the field of woodworking industry. Its products are in demand, in small industries, and on large furniture enterprises.

Automatic One-sided Cechisa Edge Banding Machine is used to favay direct edges. Machines are easy to manage. They glue the edge material from melamine, veneer, laminate and wood.

Edgeless SIETRO machine

Since Sietro machines are produced in China, their purchase is a big lottery - maybe you can get a good aggregate, which in the hands of a skillful master will serve for a long time and efficiently, but you can get an unreliable machine.