Laying sandstone with your own hands Useful advice,Plot.

Sandstone is a natural stone that nature creates. Predated sand is the main component of the sandstone, hence he got his name.

Content

What is sandstone and what it happens

The sandstone can include small shells, chemical and organic compounds, clay.

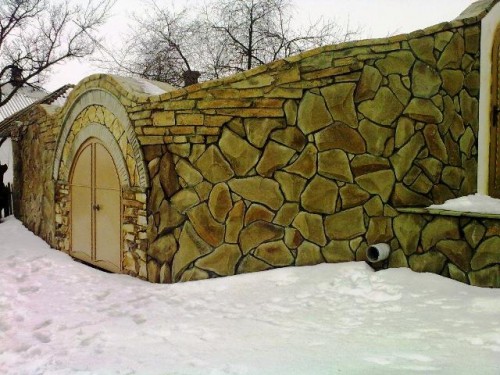

The strength and beautiful view allows you to use sandstone when booking the foundation, erection of walls, finishing houses, construction of fences and landscape design for lays down the tracks and paving platforms.

When facing facades or base, the building base is used natural sandstone stone. Staying sandstone with technology compliance protects the foundation from the effects of the external environment and gives the construction of a beautiful appearance.

When removing the sandstone, the brick poles, concrete spans, the foundation or lay the poles and spans from sandstone completely.

Depending on the place where sandstone is mined, and the processing method, the stone has a different color. Sandstone can be light gray, gray-green, tiger, or have different tones of yellow brown gamma.

The burned sandstone has red and brown shades. Such sandstone was called "fried." Fried sandstone has a higher cost, but has a beautiful appearance and increased strength due to the firing.

Sandstone yellow color - beautiful, but not the highest quality. For facade works, such sandstone is not suitable. The yellow color of sandstone says that it is not yet sufficient enough, has a small density, as a result of which in a couple of years it will begin to settle.

Application for lining of sandstone various colors makes a finish especially interesting.

How to put sandstone

Laying sandstone on the horizontal and vertical plane is characterized by surface preparation. Regardless, where are you planning to use sandstone - on the paving path, or on the facing of the building, the principles of the preparation of stone to work are the same.

Sandstone styling technology includes stone cleaning. Grilled sandstone is enough to clean from dust - it can be washed with flowing water. Sandstone who has not been subjected to heat treatment must first soak.

After soaking, the stones are cleansed with a metal or plastic brush. With the help of a brush, you will remove the sand, Il and moss from the surface of the stone. In addition, when soaking from sandstone, an excess salt is leaving - it prevents the formation of heights on the stone after laying.

Do not forget that the dusty dirty base of the stone is the key to the fact that over time he will move away from the wall.

After the sandstone ished away - spread it on a clean film, picking up the faces so that you have an idea - how the stone will be located on the wall of Lee on the track.

Laying sandstone on vertical surfaces

Rarely stones with sandstone the entire facade of the building. Usually we are lined with the base and lay sandstone with decorative elements on the wall.

Sandstone is placed on concrete or brick. Laying sandstone on a tree is not practiced. Even if you handle the wooden surface with a special solution - the sandstone will not last long there. Wood and stone have a different expansion coefficient. When the temperatures between the tree and the stone, a gap is formed, which will increase over time. As a result, sandstone slabs will completely go away from the surface.

Surface preparation

- The wall on which sandstone will be laid, clean out of contamination.

- If on the wall loose plaster - treat it with a deep penetration with the primer. The primer will strengthen the layer of plaster. But when it comes to facade works, loose and molded plaster need to be removed. The surface must be durable and smooth.

- Moisten the surface. It is not necessary to pass the normal primer surface. Sandstone is laid on cement mixtures - for better clutch, the surface must be wet. After processing the moisture, the moisture into the surface is practically not absorbed.

- With the help of dowels, secure the reinforcing grid.

- Divide the cement mixture for spray. For the preparation of the solution, use the finished mixture, or mix the sacred sand with the cement. On 1 part of the cement, take 3 parts of the sand. A spray solution must be sufficiently liquid, but not to such an extent so that it slides on the wall. Plug the mixture to make it filled the seams of brick masonry, irregularities, and completely closed the surface with a thin layer.

- Prepare a solution for laying sandstone. For the solution, 2 parts of the glue "Ceresit 117", 1 part of the sand and 1 part of the cement are taken. There is no accurate recipe for the reason that the sandstone can be laid on the adhesive solution. But experts believe that sandstone is worse on a purely glue solution.

- Stacking sandstone start upwards. You can start the laying after the spray layer drops after 2-6 hours, depending on the layer and weather conditions.

- Apply the solution to the surface. The layer of solution depends on the thickness of the stone. Rush the toothed spatula. The harder the stone, the more the teeth of the spatula should be - up to 10 mm.

- Attach the stone in the wall and press it into the solution. Under the stone should not be air emptiness.

- The solution that fell on the front of the stone immediately remove with a damp sponge, not letting it grab.

- After drying the suture solution, sandstone is covered with varnish.

- If it is necessary to trim, the plane cuts the grinder.

Sandstone laying on horizontal surfaces

Sandstone fence device

Publishing pillars for fence from sandstone is possible. In this case, it is already about horizontal stacking of stone.

The markup of the site is made, arrange a ribbon foundation, then installed formwork. Sandstone is placed with a flat side outside on a cement solution in a 1: 3 ratio. After laying each row, they give a solution to dry throughout the day.

Work with this method of the device for the fence is long and painstaking. Yes, the cost of the fence will fall into a decent amount. For these reasons, the concrete or brick fear of sandstone is more often used.

Begging sandstone sites and garden tracks

When preparing the basis for the tracks and sandstone platforms, the load is taken into account, which in the future this site must withstand.

Under the garden tracks, it is enough to remove the layer of the jam, fall asleep with sand and rubble and lay sandstone. But in order for the tracks to serve for a long time, and over time, they did not have to redo them - the surface is better to prepare thoroughly. The width of the track is recommended to do at least 60 cm.

Tools and materials

- roulette

- pegs

- twine

- reinforcing grid

- sand, crushed stone, cement, glue

- capacity for mixing the solution

- sandstone with a thickness of at least 30 mm

- drill with a mixer

- bulgarian

- shovel, spatula, trowel

- kiyanka

Operation of work in the preparation of the surface

- Post a plot. Hammer clins. Tension the beep.

- Remove the top layer of the Earth with a pipe to a depth of 20-30 cm.

- Fall off the sand with a layer of 5 cm and sink.

- For the next layer, use the crushed stone fraction 20-40. Through a layer of rubble sand should not shine. Crushed stone is also tamped.

- Place the reinforcing grid.

- Prepare a solution of 1 part of the cement and 3 parts of the sand.

- Fill the pad or path with a solution with a thickness of 5-6 cm.

- With solar weather, cover everything with a film so that the solution does not swam during the collapse. Sandstone laying can be started in two days.

- In the preparation of the surface under the garden paths with a small load, the rod is removed to a depth of 15-20 cm, then falling asleep with sand layer 5 cm and the membrane or durable film is stacked. On top of the film fall asleep with a layer of 5-6 cm.

Laying sandstone

Garden tracks can be laid in two methods - dry and ordinary.

With a dry method, after preparing the track on a layer of rubble, a dry mixture of sand with cement in a 3: 1 ratio is poured. Next put sandstone. Laying tracks starts from edge. Tiles of large sizes are stacked along the edges, the tiles are smaller. Sandstone tiles laid slightly having them in a dry mix. After laying the seams between the plates, the dry mixture is covered and spilled with water from the watering can.

With the usual - wet method of laying, a mixture of cement and sand is divorced by water, Ceresit 85 glue is added.

For the convenience of laying a stone and selection of it in size, the stone can be previously decomposed on the track. After the stone is decomposed, several tiles rises. A solution of up to 20 mm is laid on the released place. Tiles are tightly pressed and pressed into the solution. Such images is laid out completely all the track.

When grouting seams, you need to fill in a mixture of all empties between the stone.

Laying sandstone with their own hands - the process is creative. A variety of shapes and sizes of the tumor allows you to lay out it with a unique pattern.

Laying sandstone. Video.