Canopy for polycarbonate machine with their own hands Construction

Each owner of a private house owner, having a car, is trying to equip in his site if not a garage, then at least a canopy. For the construction of this design, such material is most often used as polycarbonate.

Content

Advantages and disadvantages of polycarbonate canopies

The advantages of this material are considered to be the following features:

- polycarbonate does not require prevention, because does not include seals in need of replacement;

- not susceptible to burning, at high temperatures only melting;

- i am very well missing light;

- not afraid of UV irradiation, because equipped with a special protective layer;

- has a long service life, because it does not harm the impact of precipitation and temperature jumps;

- easy installation;

- has flexibility that allows you to implement design ideas;

- polycarbonate for canopy, the thickness of which can be both small and rather significant, does not suffer from a large number of snow;

- very durable, withstands the blows of considerable strength;

- from this material, not only reliable, but also beautiful autonavissions are polycarbonate, the photos of which are presented below, is not only transparent, but also color, and the palette of shades is very rich.

The disadvantages of such structures are only a few:

- do not hold warm air;

- do not protect the car from oblique rain and snow;

- do not interfere with the attackers;

- when heated, the material is expanding greatly;

- it is subject to mechanical exposure.

Construction of carbonate autolations from polycarbonate

To date, car owners most often use two types of canopies:

- detached;

- aged at home.

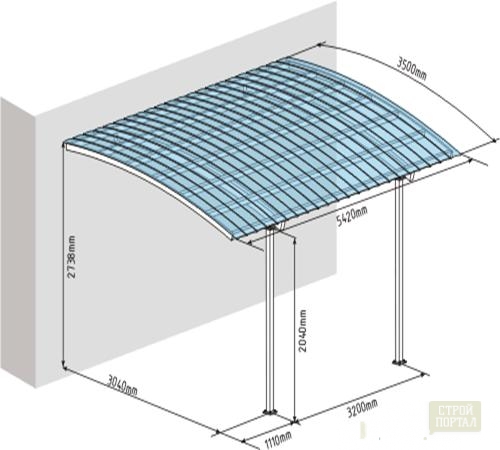

Shed-extension requires less time and effort to build, and also saves funds and is sometimes worthy addition in the design of the entire site. His one side is fixed on the wall, and the second is based on a couple of columns. To make the construction of stability and reliability, or poured with concrete or installed on a prepared pre-concrete site.

Frame for canopy from polycarbonate, as well as support racks create either from a wooden bar or from a metal profile. But in some cases, supports can be brick, stone or concrete, for example, if this requires the overall design of the yard or at home.

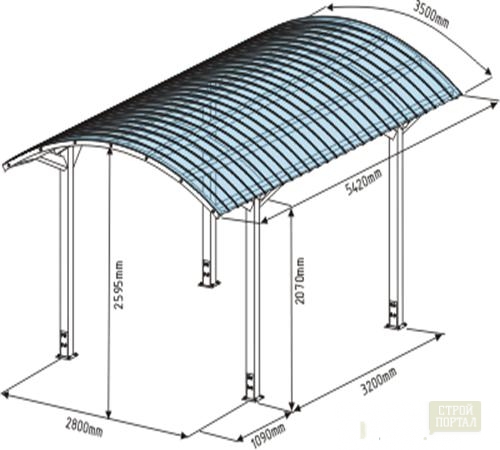

A canopy standing inpatient, installed on the rack completely. Their number should not be less than four units. The step between the supports should be from 1 to 1.5 meters. It depends on the severity of the roof of the canopy and the framework of the carcass.

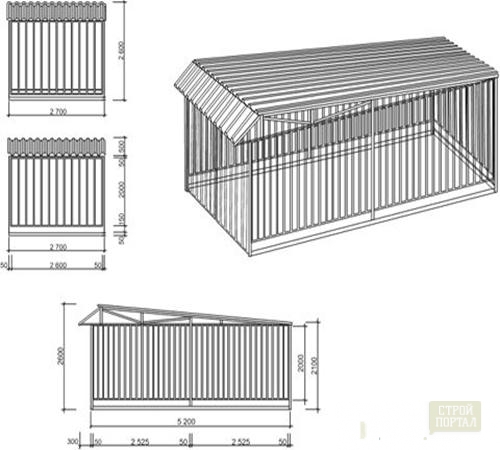

The sizes of the canopy vary depending on how many machines are planned to put there. The shape of his roof can be any:

- arched;

- spherical;

- wavy;

- direct, etc.

Read more about the sizes

The calculation of the polycarbonate canopy is made as follows: if there is one car under it, the length of which is 4 meters, then the minimum length of the canopy in this case should be equal to 5, and the width is 2.5 meters. If the design is constructed for a massive machine, such as a jeep or minivan, then the size of the canopy must be increased by 1-1.5 meters, i.e. Length - 6.5, and width is 3.5 meters.

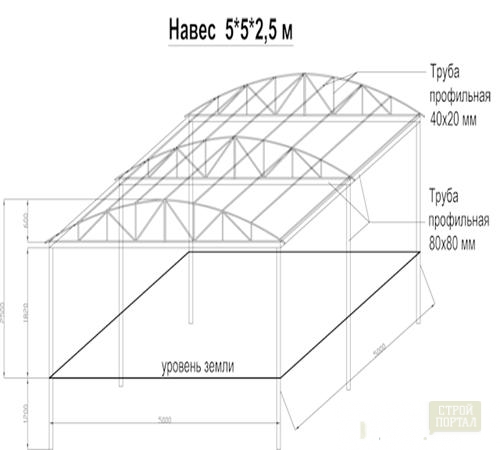

The height of the structure is calculated, pushing out from the height of the car with a loaded top trunk. At the same time, it is not necessary to forget that too high canopy well protects from precipitation and allows winds to shake the roof. Specialists recommend designing the design so that this parameter does not exceed 2.5 meters.

How to make a carport of polycarbonate

Build canopies for the machine from polycarbonate it is not at all difficult. It takes only a little experience with a saw and a hammer. When working, you need to observe such a sequence:

1. First of all, it is necessary to create a drawing. It indicates all the details of the design, its features, sizes, places of fasteners, etc. It is easier to imagine the view and location of the future building. Below for example, samples of polycarbonate canopy drawings are presented:

2. The next step is the foundation laying. There are two options here:

- acquisition of ready-made foundation blocks and installing a cowpack on them using brackets and corners;

- digging the meter depths, in which the supports are inserted, and the concrete solution is poured, and the place around is masked by paving slabs.

3. Build a frame. If the first option was preferred when the foundation is preferred, the framework of the frame may immediately after installing the supports. When using the second option, you should wait about a week until concrete dry out. If at this time there is a hot and dry weather on the yard, then the slain plot should be periodically saved, otherwise cracks can go from dryness.

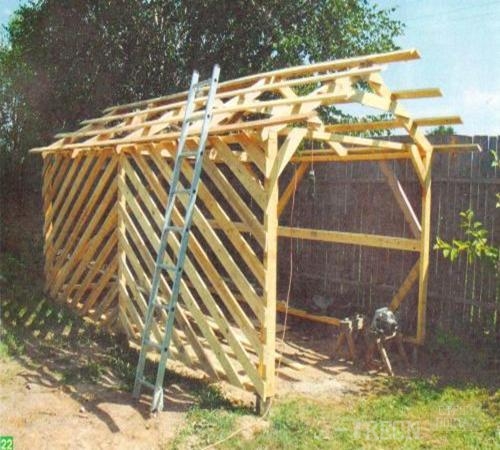

For the frame assembly, a material has a smaller cross-sectional area than at the racks. So do, because the load on it is not so significant as on supports. Early frame in such a sequence:

- tie racks with each other;

- secure transverse beams on them;

- collect rafters;

- pribe the crate.

4. Roof arrangement. Polycarbonate is cellular and monolithic. These species have the following differences:

- cellular polycarbonate is more convenient to assemble due to the fact that due to the presence of emptiness it has a low weight, but the monolithic polycarbonate is able to withstand a large amount of snow;

- If the choice fell on a cellular polycarbonate, then the frame and support can be thin and light, and if on monolithic - you should choose more reliable and heavy material, which will entail certain difficulties when installing;

- cellular polycarbonate is much cheaper than monolithic, but the latter will last much longer.

To set the selected type of polycarbonate, you need to measure the framework and cut off a piece of material of the required size.

If a cellular polymer was purchased for installation, it should be installed so that the sheet channels are located strictly perpendicular to the Earth, otherwise the water from precipitation will not depend on the ground independently, and will accumulate inside the sheet. After it falls in dust and create a very ugly view from the side. To clean this dirt, you will need time and effort. When choosing a monolithic polycarbonate, such a problem is not relevant.

After a piece of the required size is measured and cut off, you need to sew holes for fasteners. It is done in advance, before the installation of the material starts, otherwise it will be easy to damage.

When drilling holes, it is important to take into account the next nuance - the hole itself should be slightly wider than the self-tapping screw. It is necessary so that the material, expanding and narrowing from the temperature differences, did not crack in the fastening places. But if the holes are too high, then over time they can clog mud. If it happened, protect them with sealant or rubber gaskets.

The lower edge of the material is closed with a perforated ribbon, and the upper one is solid.

Tips for the choice of material

By purchasing polycarbonate, you need to remember such important factors as:

- Sheet thickness. It happens 4.6.10 mm. The choice depends on the form of the future canopy. If it is domed, with steep slopes, then it is better to choose a thin sheet, if straight and color is thick. Also, more than 6 mm material is preferable for regions in which snow drifts are observed.

- Protective covering. There is a material equipped with a special film or without it. It is better, of course, to reinstate and choose with protection, to then have confidence that the construction will be durable.

Sheds from polycarbonate, video: