Furnaces for home on firewood do it yourself Useful advice,Construction

Despite the fact that the majority of settlements of the country uses gas for household needs, firewood remains one of the most popular fuels. Furnaces on firewood are installed for the heating of private houses, and even apartments, in the regions where there is no centralized gas supply. They are often used as an alternative source of heat in country houses and at dachas where it is irrational to install a full-fledged heating system with boiler, radiators, etc.

Content

Compared with gas, wood furnaces cannot boast of high efficiency and the level of fuel supply. They are needed by a constant supervision, so in the heating period on vacation, it is unlikely to go. However, in some regions, this type of fuel is available in unlimited quantities, which causes its popularity. In favor of firewood, it can say a constant increase in the efficiency of solid fuel boilers and the duration of fuel burning. This mainly concerns pyrolysis models that can work on one bookmark to 24 hours.

Simple furnaces that work on firewood can be made independently. With certain skills it is possible to do both simple metal models, which are called "bourgeitors" and complex brick furnaces of the "Swede" type. Currently, there are a large number of projects of various wood-burning furnaces of any power and for a wide range of applications. They can only be heating, only cooking or combined. And the latest developments are quite suitable even for heating water. About how to make a furnace with your own hands - Next.

Selection of firewood furnaces

The variety of wood stoves sometimes puts in the difficulty of the hosts of the room, where they are planned to be installed, in choosing the most optimal option. When the furnace design is thinking, the following parameters must be taken into account:

- Room area. For a small country house, accommodation in which in winter it happens only from time to time, the installation of a complex design with a built-in boiler does not make any sense. A small burzhuyka cooked from metal is quite suitable for these purposes. For residential buildings of a large area, a brick "Swede" is best suited, which can drop out sufficiently large squares.

- Functionality. In industrial premises, where there is a need for heating only, small models are used, calculated only on this function. In private houses, where there is no other fuel, the furnace can be done with the function of cooking, as well as water heating. It is worth noting that in homes, where there are no power supply interruptions, residents prefer to prepare and warm water using electricity. Wood furnaces work only in the heating period.

- Production material. Here it is necessary to understand the difference between the thermodynamic properties of materials. For example, a metal furnace will quickly heat the room, however, due to the large thermal conductivity, such furnaces are cooled pretty quickly. Chamotte brick acts as a heat acceumant. To warm up such a furnace, it will take a little more time, but it is necessary to maintain heat, thereby providing a more comfortable temperature in the room.

Heating furnace with your own hands - "Bourgehog"

"Bourgehog" is the easiest version of the wood furnace, so its manufacture does not take much time and means. The most optimal material for the furnace case is a sheet metal with a thickness of 5 mm. If you take a sheet thoroughly, the weight of the product and its cost will grow several times, the thin metal will not withstand the temperature load and it will simply lead.

The bourgeitine design is extremely simple:

- It consists of two cameras: Fires and an underduction chamber through which air is supplied and a cold residue is cleaned.

- In the end wall, the bourgearies have two doors: a large door for loading the furnace and a small for cleaning ash.

- In the upper wall of the bourgear, a hole is made for the flue of the chimney. The diameter of the opening is approximately 100 mm. The nozzle is made from the usual steel pipe of the corresponding diameter.

- In order for the metal to experience less loads, the walls are enhanced by rigids from a steel corner or profiled pipe. In this case, even overheating in the furnace will not cause damage to its design.

- In some models, cooking surfaces are arranged. In this case, the top cover of the furnace should be of the thicker steel than its side walls. It makes holes in which burners of less thick steel are installed. Do it in order to achieve different temperatures on the cooking surface and the burner. On one it will be convenient to cook, and on the other - to fry or warm up food.

- Inside the furnace, a grate grid is installed, which serves to access the air to the flue chamber and removing the burned oland residues. This item can be like purchased and done with your own hands.

Order of work:

- Before the start of the manufacture of burzhuyki, it is necessary to draw up drawings of metal furnaces with their own hands and cutting basic parts. The furnace case consists of three pairs of details: Front and rear end panels. In the front, it is necessary to cut holes for the fuel and cleaning doors. Their sizes should be applied on a metal sheet and cut with a grinder. In the upper lid, the hole is cut on the installation of the chimney nozzle and, if necessary, a hole for the burner.

- Also, according to the measuring lengths, the ribs of rigidity from a corner or profiled pipe are cut.

- After all the blanks are cut, welding work. For welding, a welding machine with Woni electrodes, Ano with a diameter of 4 mm is used. When welding, the bourgearies need to be remembered about the tightness of the welding seam. Otherwise, carbon monoxide will penetrate the room, which is fraught with deposits.

- The bourgeitogo is going to bottom-up, the top cover is welded the latter. After the end of the welding work, the seams are cleaned with the help of grinding.

- Then the furnace doors are hung and pondered with locks and the legs in the corners of the bottom cover are welded. The last stroke will be painting the furnace for the obstacle corrosion of the metal. Simple paint is not suitable for such work. For painting the oven requires special heat-resistant paint. It is better to carry out painting with a collapse of 2 layers.

Very often for the manufacture of bourgeois, pipes of large diameter and even old gas cylinders are used.

Production of long burning furnaces with their own hands

This model is designed to burn fuel with low oxygen access. Due to this, the combustion time of one wooden laying increases markedly. In such a furnace, the fuel is not lit, and the tweet, while ensuring high temperature.

The design of such a furnace resembles a syringe. It consists of imagined and the furnaces that are separated by a grate grid. The difference in the ovens of long burning from the burzhuyka is that the air does not appeal at the first, but through the movable arch of the furnace, which is also called the press.

When loading a furnace, the press rises up, freeing the firework, and after completing the bookmark releases, crushing the firewood with its weight. At the same time, the fuel is compacted and after arsion is simply tweet. Arriving, firewood falls in thought, and the press gradually falls down.

This oven is done quite simple:

- First cut a piece of pipe with a diameter of 500 mm on the required length. Then, from a steel sheet with a thickness of 5 mm, 3 circles are cut. Two of them must correspond to the diameter of the pipe, and one - a few millimeters less. A pipe with a diameter of 100 mm is welded to it, which will be supplied to air and several steel strips from the reverse side. They are needed to give a circle of rigidity and increase its weight.

- In the housing of the furnace, 3 holes are cut: for the furnace, for pushed, for chimney. Then the cutter is welded to the bottom of the furnace. Next, a grate grille is installed between the door of the furnace and pondered. In the cover of the furnace is made a hole for the press tube, so that it can be lifted. The only disadvantage of such a furnace is that it is pretty hard to download alone, always requires the help of the second person to keep the press.

The last step will be the installation of the upper cover. It is boiled in a circle. The latter welded the nozzle for the chimney.

There is a durable burning furnace as follows:

- Originally risen the press of the furnace and firewood is superimposed in the furnace.

- Then the press is lowered and fuel is set up.

- After it starts smoldering, the furnace door closes.

- As the fuel and lowering of the press is roasted, the fuel loading process is repeated.

- To give a new furnace of the commercial type, it is covered with heat-resistant paint.

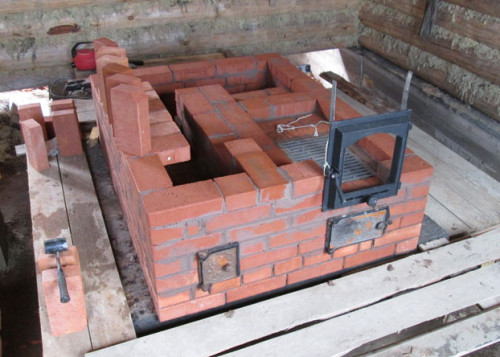

Brick oven with your own hands

The construction of a brick wood furnace requires special knowledge and skills. The difficulty building such aggregates is that they have a lot of weight. That is why the construction of brick furnaces is performed on a separate foundation. In the production of work on brickwork, it is necessary to clearly comply with the county. Each row has its own unique profile, because the furnace design is designed for a special movement of hot gases for more efficient operation. Construction of brick wood stoves - real art, which is why, as a rule, there are only professional liveniks.