Methods of vapor insulation bath Baths, saunas and pools

The bath is the place in which almost everything loves is like, and the bath procedures have long been known for their healing properties. But the fact is that some visitors prefer to bathe at high temperatures, and some simply do not tolerate them. In order to create optimal conditions for people with different preferences, you need to know how to make a steam barrier bath.

Content

The need for vapor insulation

There are some factors capable of negatively affect the service life of the bath building. It is necessary to think about them even when the architectural project is being developed, and if possible or eliminated, or reduce the action to a minimum. Among these factors are the following:

- adverse effects of the external environment;

- features of the local climate;

- seismic accuracy of terrain.

Along with moisture from rain and snow, acting on the construction of the outside, the moisture coming from the inside has its own influence. This is a condensate formed due to steam.

To reduce the harmful effects of the factors described above, there are specially intended materials, including vapor insulation. Some of them in addition to their basic functions are also an energy-saving layer. If you correctly perform vapor barrier for the bath, the efficiency of the heating devices will increase significantly. Thus, it will be possible to reduce the cost of electricity used to heat the room.

In addition to savings, high-quality vaporoselation materials can contribute to the establishment of a special microclimate, optimal to obtain the effect of bath procedures.

Modern vaporizolation performs additional functions - protection against wind and water. Thanks to her, moisture in the form of rain and snow does not fall inside, and steam penetrating overlapping quickly dishes. Therefore, the voids stipulated by the structure remains dry and the life of the construction increases.

Methods that bath ceiling is isolated from couple

In the bath, the ceiling vaporizolation is needed at mandatory, because Hot evaporations are concentrated near him, and their leakage cannot be allowed. They must accumulate inside the bath and stay in it, but in no case to seize in the overlap.

In recent years, many options for laying vapor barrier on the bath ceiling was invented, but some still love old proven methods more.

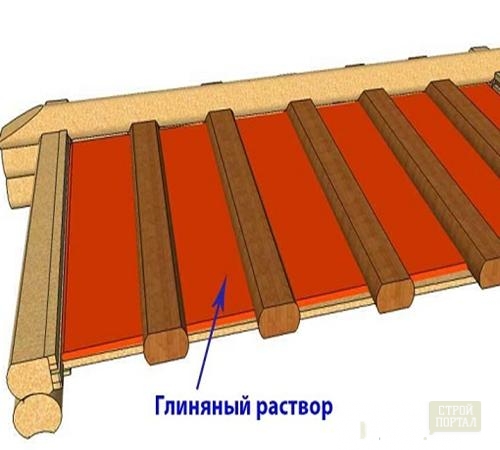

1. The ceiling in the bathroom, built of logs, is coated with a board, the thickness of which is at least 60 mm. As vaporizolation, either waxed paper or aluminum foil, or a thick cardboard with impregnation from the olifa. After that, the selected material is covered with a layer of clay, and the insulation is already hardened.

2. Another method is to cover the ceiling beams by unedged fifty-millimeter boards. From the pair, along the beams they hold them other boards of the same size. The linden or aspen can be used as finishing material. It is fixed on supporting boards, and it is necessary to withstand a small distance between the trim and insulation. The material layer is placed on the boards and after cover, as in the previous method, the clay layer and apply the insulation.

3. But today, clay for these goals is not used almost anywhere. It was safely replaced by hygroscopic materials, which also have insulating qualities and capable of performing their functions even with high humidity. There is a method called "Pie", along which several materials layer layer are stacked by each other:

- 2x2 cm beams are joined to the boarding ceiling;

- two layers of olifa are applied to all wooden parts;

- on the beams are laying boards, they leave the gap between them. It will be useful in order to protect the cladding from the big humidity at high temperatures;

- polyethylene film, rubberoid or reinforced foil are placed the following layer;

- at the last stage, a twenty-salted layer of a mixture of sand and slag is poured.

Inside the steam room itself, the thermal insulation of the ceilings is extremely necessary, but in the other rooms the lining is naked directly to the "rough" surface of the ceiling.

Parosolation of walls bath

As well as the ceiling, the walls of the baths also need isolation. It stacked under the lining and promotes heat saving. Materials are most often used as:

- aluminium foil;

- polyethylene film;

- tol;

- pergamine;

- ruberoid.

To remove the condensate in the steam room, it is better to use aluminum foil for other premises, tol, rubberoid and parchment are suitable for other rooms. For the Parims, the three last material is not recommended to be applied, because, heating, they begin to smell well and highlight toxins, dangerous to human health.

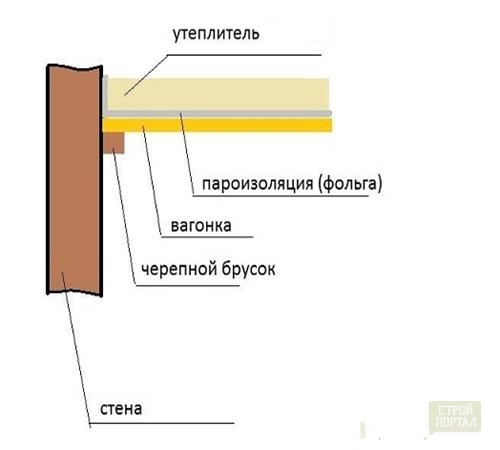

Competent vaporizolation of the walls is mounted in such a sequence:

- fiberglass plates or mineral wool are used as an insulating layer;

- the following layer is laid out aluminum foil. This layer will prevent the leakage of steam and heat loss;

- the installation process is similar to the fastening of thermal insulation on the ceiling. It is also fixed either with nails, or a stapler, and on top there is a cladding.

Overview of materials of employees for vapor barrier

The most popular and simple material for vapor barrier in the bath is a dense film from polyethylene. In the steam room and the soul most often use aluminum foil, and in dry rooms - kraft paper.

If the budget is limited, then the roof uses clay to which sawdust is added. It is applied by a two-chamber layer. This option is cheap and practical, but has such a minus as high labor costs and the dirt left.

In addition, there is an option to mix peat and perlite and pour the clay layer with a mixture, and after it is coated with a film from polyethylene or a foil.

In the list of the best vaporizolizing materials there is a stipal, it is common and self-adhesive, saves heat and has heat resistance.

At this time, the highly spread received films for vaporizolation Armitek and Isoltex. The first is placed on the inside of the room for lining, the second is from above on the heat insulating layer.

There are also materials that are distinguished by strength and ease of use, which serve not only for vapor barrier, but also for insulation, such as foaming. It consists of foamed foaming, coated with foil. It is used even in pairs, because It is not afraid of either moisture or hot air. Foaming is fixed on the wall or ceilings by conventional nails or construction stapler. Its coating contributes to maintaining in the pair of the right temperature, it does not give dampness and fungus.

Another excellent foil material is the isospan. It is made on the basis of kraft paper and is an excellent choice for vapor insulation baths, saunas and other wood buildings.

In addition to the listed, the vapor barrier function will perfectly perform the usual foil in rolls or slab fiberglass. This material is equally well suitable for walls, and for ceiling, and for overlaps. He moisture-resistant, not afraid of frost, is not susceptible to burning and has a very attractive cost.

Several tips for working

By mounting a vapor insulating layer on the ceilings and walls, the joints of the joints should be sealing the scotch and aluminum foil under it. Such actions exclude the risk of drafts.

It is mandatory between the facing and insulation, the gap is 10-20 mm. He will serve in order to avoid wetting the finish, because A wet atmosphere and high temperatures are observed in the pair all the time.

Usually, even the most reliable vaporizolation is trying to disguise with decorative trim. As it, boards from aspen and linden are usually used, as well as the Euro woman, which is different.