Summer water supply device in the country Useful advice,Plot.

Without water supply in the country can not do. Summer water supply is the most common version of the water supply of country sites. Thanks to the system of summer water supply, a full watering of plants is provided, time saves, work is facilitated. The use of pipes from new materials instead of traditional metal allows you to make a water supply much faster, easier and cheaper.

Content

- What water sources are used for summer water supply

- What are the schemes of summer water pipeline

- How to make a plan of summer water pipeline

- What materials, devices and tools are required to arrange the summer water supply

- CHEMA of the collapsible summer water pipes from hoses

- Summer water supply assembly procedure

- Year-round water supply

- How to install autonomous water supply

- Installation of pumping equipment

- Installation of stationary summer water pipeline

- How to assemble a summer water pipe from plastic pipes

- Summer water pipeline service rules

Summer version of the water supply is quite suitable for seasonal accommodation in the country. It is used both for watering and for household appliances, water supply to shower, bath, swimming pool, makes comfort in summer life. In winter, its use is undesirable or not at all. Summer water pipe is simpler and costs cheaper than year-round, but less durable.

What water sources are used for summer water supply

The primary task with the arrangement of the summer water supply is the choice of water source.

Types of water sources for summer water supply:

- Central highway.

- Well.

- Well.

- Natural reservoir.

- Reservoir for rainwater.

Central water supply

Perfect option. To connect to the steel trunk tube directly under pressure, use the overhead of the tee (saddle). It is installed on the input point and is fixed with bolts. After that, the ball valve on the Fubnitka is mounted. Through the crane with a drill, a hole in the center tube is dried and the crane is immediately closed.

Natural reservoirs

Ponds - river, lake, pond. The lack of use of open water bodies for the country water supply is the need to clean water from extraneous impurities.

Well

There are two types of wells intended for water intake - artesian and sandy.

For the sandy well, filter equipment will be required due to the large content of sand and clay. The water supply speed is on average of about two cubic meters per hour, which is quite enough for country sites and small country houses.

Water in the artesian well rises to the surface under pressure. The resulting amount of water is 10 cubic meters per hour. The additional advantage of the artesian well is cleaned water due to deep drilling. Such wells are durable: on average, the service life is 50 years.

Well

The depth of the well depends on the level of groundwater and usually does not exceed 15 m. The deficiency of the well includes the content of many harmful impurities and a small provision of water - at an hour of about 200 liters.

Rainwater Tank

As tanks for collecting melt and rainwater, pools or artificial ponds, plastic and metal tanks are used: tanks, barrels, chains. Drainage pipes are laid or dried roofing pipes. Water from tanks for winter can not be merged, and so that the walls of the tank are not numbered, several plastic bottles are placed, half filled with water or sand.

What are the schemes of summer water pipeline

After the water source is determined, it should be solved as to choose a type of water supply: year-round or only summer.

Summer water supply on the household plot, dacha, garden is used for watering plants, filling artificial water bodies, water supply to shower, bath, summer kitchen and other household needs. In winter, such a water supply system is not used.

Summer water supply is collapsible and permanent.

Summer collapsible water supply

In the event of a choice of collapsible water supply - pipes or hoses simply lie on Earth or raised over it. Such a water supply is easily assembled from conventional silicone or rubber hoses by connecting them between plastic or steel adapters.

There are special jacks on sale, which have a ribbed cone for the hose on one side, and on the other hand, a convenient elastic connector that allows you to connect and disconnect the hoses in one movement. Such latches create a durable joint.

The benefits of summer collapsible water supply include:

- Fast assembly and disassembly.

- Quick search for damaged pipes and elimination of holes.

- The cost of the collapsible water supply is lower than stationary.

Disadvantages of summer collapsible water supply:

- Pipes interfere with movement.

- The high probability of theft.

- The need for assembly and disassembly at the beginning and at the end of the watering season.

Stationary summer water supply

The constant water supply is paved under the ground. For these purposes, thick-walled rubber hoses or plastic pipes can be used. Plastic water supply on the summer site is placed under the tilt to the drain valve near the water supply source. Prior to the occurrence of cold weather, the remaining water from the pipeline is completely reset to avoid freezing and damage to pipes.

For a permanent scheme of the summer water supply, the pipes are placed in the ground at a small depth, and watershed taps are removed on the surface.

Advantages of stationary country water supply:

- Pipes are located underground and do not interfere with walking, shipping on the cart.

- Installation of summer water supply is carried out once.

- Underground layout of pipes serves as protection against theft.

- Simple system preparation for winter, just open the plum valve and release all the water.

The disadvantages of the stationary summer water supply are:

- Large material costs than when building a collapsible water supply.

- The time-consuming installation of the water supply is due to the need to dig a trench and lay pipes under a slope.

- Difficulties with the search and repair of holes in the pipe.

How to make a plan of summer water pipeline

Before purchasing pipes and proceed to the assembly, you need to think about the diagram and make a preliminary drawing, specify all the sizes in detail. It should be solved in advance: where to bring water, where the water intake points will be located, how much it will be necessary.

After that, with the help of pegs and twine, they perform the breakdown of the future plumbing track on the land plot, measure and calculate the necessary method of pipes, the number of corners, tees, cranes and other consumables. In any case, the small supply of component parts will prevent. A good plan is the key to success, saving forces, time and money.

The project should be marked with existing and planned underground communications, tracks, buildings, plantings, especially if the constant scheme of the summer water supply is mounted. When a stationary summer water supply device is prepared by trenches for styling pipes. The depth of the pipe laying is usually 30-40 cm.

However, if the pipes run under the beds, and there is a probability of their damage to a shovel or a cultivator, then the depth of the trench is increased to 50-70 cm. This is a time-consuming process, but to replace the tubes and eliminate the flow even more difficult. Pipes overlook the surface of the earth only in places of water supply.

When planning a constant water supply, it is important to remember that all pipes in the trench are laid under a slope towards the connection to the water intake. In the lower part of the pipeline, plum valve is installed. This will allow you to lower the water for the winter and avoid damage to the pipes. It is necessary to determine in advance the places to summarize the water.

The number of consumption points depends on the location of the beds, greenhouses, summer shower, bath, pool. In order not to tolerate the hose from place to place, it is wiser to remove the pipes in 5-10 points. Such hydrants are connected to the length of the hose with a length of 3-5m, which ensures watering each individual zone. All consumption points are mounted by bayonet for quickly connecting the hose or automatic splashing system.

Before cut off the hoses or sawing the pipes, you should thoroughly measure the required length, put marker labels and only then proceed to the cutting. Such an approach, according to the principle, death seven times - a rejection once, will save from annoying mistakes and additional costs.

What materials, devices and tools are required to arrange the summer water supply

For the installation of summer water pipeline, the following materials and tools will be required in the country area:

- Pipes and hoses.

- Fittings and tees.

- Couplings compression with external thread (20; 1/2).

- Adjustable key, gas key, wrenches No. 17-24.

- Special cutter for plastic water pipes or hacksaw for metal.

- Shovel.

- Scrap.

- Soldering iron. If you plan to connect pipes by welding, instead of fittings and a gas key use a special electric soldering iron. Solders are inexpensive, and in some construction stores are even issued for rent.

- Ball valve 1/2.

- Corner compression 20 mm.

- Tee compression 20 mm.

- Sedley 63 (1/2).

- FUMNIK.

- Adjustable key, gas key and wrenches No. 17-24.

- Grinding paper.

- Knife, roulette, pencil.

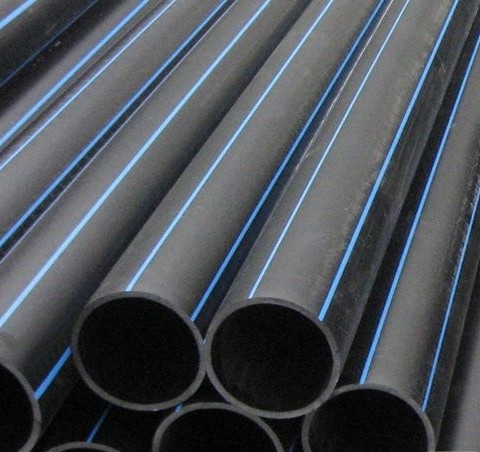

Pipe

Pipes for assembling the summer water supply on the average summer cottage area of \u200b\u200b10 acres are preferable to plastic or polyethylene (diameter 20-25 mm, length 100m). Reliable uninterrupted water supply largely depends on the quality of pipes. Polypropylene tubes of green from the "Banningher" with a diameter of 25mm have proven well. They are more expensive than traditional white pipes, but they are resistant to temperature differences and even frosts withstand.

Hoses

Instead of pipes, you can use hoses.

Rubber hoses with thick walls, reinforced by kapron fibers, more stronger and more durable, they will reliably serve for 15 years.

Fittings and tees

Wiring of summer water pipes is performed using tees, and special fittings are best suitable for connecting plastic pipes. The use of fittings allows you to collect a country water supply in just one day. At the same time, the junction is sealed, and if necessary, the design is easily disassembled.

CHEMA of the collapsible summer water pipes from hoses

The simplest design is the summer water pipe from flexible hoses. The collapsible system from hoses is pretty simple. With the onset of heat, the hoses connect to the pump and laid on the surface of the Earth so that they do not interfere with the free movement in the country area.

Hoses are rubber and silicone. For their connection, purchased or homemade devices are used: steel and plastic adapters, jumpers, pieces of pipes or special latches, allowing you to quickly disconnect or connect two segments of the water supply. On the one hand, they have a spring connector, and on the other - "ERS". Such a fastener provides a solid and reliable connection.

Now we are publishing incubating hoses with special reinforcement. There are corrugated hoses that are capable of stretching for a significant length and are very compact in a compressed state.

Hoses and components for drip irrigation appeared on sale.

Basically, the plumbing from hoses is used for watering in the country. In the fall, the hoses and pump are folded and removed into the room.

Summer water supply assembly procedure

Determine where to place the conclusions: entrance to the greenhouse, the vehicle platform, summer shower, washbasin, swimming pool, flower garden, etc. The hose is more convenient to attach and shoot at the intersection or on a wide track.

Measure the distance and calculate the necessary pipe length. Plastic or polyethylene pipes are best suited for arranging summer water pipes. It is convenient to connect them with flexible hoses. This design of the water supply is easy to remake. You can connect pipes with special plastic fittings or by soldering. In addition, tees, cranes, corners are required for assembling the summer water supply.

Pipes are preferably to touch for the purpose of preservation and increasing service life.

Check the pressure in the pipeline. If from the crane, open completely, water is pouring under good pressure, then enough pipes of small sections - 20 mm. With low pressure (less than 2 bar), you should not install more than three output points, as they will not be able to work simultaneously. With low pressure, it is recommended to take the pipe more - a cross section of 25 mm. Larger pipe pipes are also used in large sections with a length of more than 30 m.

As a rule, an introductory crane or a valve with a diameter of 1/2 is installed on the site of the central highway and pipeline of the site (marking 15) with internal thread.

PND tube trails to the introductory crane using a coupling. If the tap with internal thread is, respectively, the coupling is with external, and vice versa.

A tee is put on the pipe for the pipe, from a tee - a piece of the pipe that the hose is worn through a crane with an adapter. For pipeline with a diameter of 20mm suitable:

- coupling with outdoor thread 20 mm on 3/4,

- 3/4 crane with outdoor or internal threads,

- 3/4 hose adapter with internal thread.

For pipes with a cross section of 25 mm, components are used:

- Crane from the same PND 25 on 3/4.

- Adapter for hoses with external thread 3/4.

Also necessary:

- Coupling on the introductory valve.

- Tees.

- Sets for fastening hoses at output points.

- Pipes.

- FUM tape for sealing threaded connections.

- Takes to install in places turning pipes.

First of all, all threaded connections are collecting.

The main task when assembling threaded connections is to prevent leaks. In the threaded connection on one side - external thread, on the other - internal. On the outer thread tightly and without folds, a fum-tape is wrapped in 6-8 layers clockwise (the thread is turned up). Then they screw the details, tightly pressed one to another, trying not to squeeze. Then slightly tighten with a gas key.

To secure in the coupling, the pipe is smoothly cut off with a knife or fine-grained hacksaw to get a smooth edge. A little weaken clamp nut. Tightly insert the pipe. At the same time, the pipe is approximately at a depth of 5cm, first rests into the rubber sealing ring inside the coupling. It is necessary to push the pipe for another 2 cm further so that the pipe passes through the ring until it stops. After that, twist the clamp nut manually.

The hose can be attached to the water pipeline using quick-use couplings. Couplings are different modifications, the main thing is that they match the diameter of the hose. Included with couplings for sale all sorts of irrigation pistols, sprayers.

Very comfortable couplings with aquastop, which overlaps the water when disconnecting or replacing the polyvalka or pistol, which eliminates the need to turn the crane.

Summer water pipe can be equipped with a timer, and then watering will be carried out on a schedule, even in the absence of hosts.

Year-round water supply

Most often, water from the well is served using a submersible pump. The pump power is chosen depending on the depth of the well. For a depth of 10 m, "Aquarius" or "Rouh" is suitable. For water intake, a much more powerful pump will be needed.

When the year-round water supply device in the country, the pump is connected to the voltage source, and the cable and plumbing are paved in conjunction in a single casing collected from plastic sewer pipes. The casing serves to protect the water supply from mechanical damage and moving.

The depth of the trench for laying the water supply should be below the level of primer of the soil. It is possible to dig up such a trench - the case is time consuming, it is possible to relieve the task, I dug a trench to a depth of 60 cm, and on top of the pipe to fall asleep layer of insulation with a thickness of 20-30 cm. As a heater, sufficiently durable materials with low moisture absorption are used: foam crumb, polyethylene, furnace slag, ceramzite .

Near the well, the veil 70x70 cm and a depth of 1 m. The pit is used to connect the pump to the water supply, and, if necessary, quickly disconnect and remove the pump. The veil walls are placed brick or strengthen the boards with antiseptic impregnation. The bottom is poured with concrete solution or fall asleep with rubble and compact. In the pit, the tap tube with the "heroish" for the hose connected to the pump, as well as the electrical cable is removed.

So that the water in the pump hose does not frozen, the impressions are insulated. At the bottom of the water pipeline make a small drain hole with a diameter of about 1 mm, due to which the water in the water supply system slowly flows into the pit and does not freeze in winter.

The lack of such a scheme is a permanent humidity in the pit and a minor loss of water.

To safely turn on and off the pump, a waterproof outlet is installed or a sealed contact connector is used.

In the conditions of the streets, most often put conventional cranes with cranes, and even better bronze or cast iron valves. Ball cranes use undesirable, under the action of atmospheric precipitation and temperature fluctuations, they quickly fail.

The most complex node of the year-round water supply is the "Fatal" watersum assembly, located in the unheated room. Most often, special devices are used for such purposes - watershed columns. A significant disadvantage of the speaker is considered the high cost of equipment and complexity of installation.

How to install autonomous water supply

If there is a central highway, then install the summer plumbing on its site is not a lot of work. Autonomous water supply - task more complicated.

Ideally, the scheme of the autonomous water supply is in parallel with the design of the house and the site: determine the location of pipes and mechanisms, perform a phased plan, calculate the estimates, the equipment is purchased. For a boiler and watering unit, a small room is usually distinguished by an area of \u200b\u200b2-3 m² on the first floor. It is convenient to monitor and adjust the water supply process if the technical unit and the water input node are installed in the same room.

The autonomous water supply system includes the following equipment:

- Pipes (metal, metalplastic, polypropylene).

- Fittings and cranes.

- Watering equipment (pumping station, submersible pump).

- Pressure adjustment devices in a plumbing system (pressure gauge, pressure relay, hydroaccumulator or expansion tank).

- Electrical equipment with automatic protection.

- Filters for water purification from harmful impurities and suspended particles.

- Water heater (preferable accumulative).

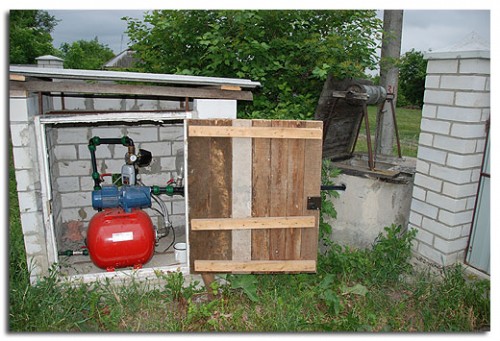

Installation of pumping equipment

As a source of water, a pre-prepared well, a trapped spring chamber, a well is used. Each of the sources has advantages and disadvantages. For example, in the well water, the water is cleared, but expensive drilling. It is much cheaper to dig a well and install a submersible pump with a three-step filter for water purification.

The following types of pumping equipment are distinguished from the source:

- Submersible pump.

- Surface pump.

- Automatic pumping station.

Submersible pump

Used at a water level of 20 m, works silently. An additionally required hydroaccumulator, filtration unit, automatic block and distributing assembly with reinforcement with reinforcement pump valve models. For contaminated water sources, it is recommended to choose a pump with a stainless metal impeller.

Surface pump

It is used at a water level less than 8 m. Installed indoors, connected with a well-dried pipe.

Automatic pumping station

The electric motor and the hydraulic part are separated by the partition. The generator, diesel or gasoline, is used to pump groundwater and watering the plot. The station includes: pump, hydroaccumulator and automation unit. The hydroaccumulator serves as a spare tank and limits the frequent switching on the pump. Inexpensive stations work noisy, so it is better to install a new generation pumping equipment.

Installation of stationary summer water pipeline

For the device of a constant design, plastic or polyethylene PND pipes are used, which are connected by flexible hoses.

Such a connection allows you to easily and quickly remake and improve the entire pipeline system. Another way of installation is welding with an electric soldering iron or a compound with special plastic fittings. Pipes are placed in shallow grooves (30-35 cm) and fall asleep.

Only cranes are removed on the surface of the Earth. Advantages: no obstacle when walking, mugging lawn and using a truck, a more aesthetic look. If you wish the pipe or hoses, it is easy to dig and disassemble. The lack of an underground construction is that there is a possibility of accidental damage to the system during earthworks.

To fall in the fall, it is easy to lower the water from the pipeline, create a small slope for drain. In the lowest part of the water supply, the valve is installed: through which the drain is carried out so that in winter the frozen water does not break the pipes and hoses.

It is especially important to ensure the safety of the power grid. For this purpose, sealed connectors and moisture sockets are used.

Water pipes of any type, summer collapsible or permanent, should be done in such a way that it is easy to eliminate an unforeseen breakdown, without resorting to the complete dismantling of the water supply.

How to assemble a summer water pipe from plastic pipes

With the arrangement of the summer water supply under the conditions of the positive air temperature and the use of only cold water, almost all types of polypropylene pipes will be suitable. The service life of PN-10 pipes calculated for water supply with a temperature of 30 ° C and a working pressure of 11.1 kgf / cm 2, is 50 years; PN-20 pipes intended for transporting hot water 60 ° C at operating pressure 10.9 kgf / cm 2, Loading even longer.

The bulk of the summer water supply is better made from pipes 25 mm. Ligger diameter pipes do not provide rigidity design. 2 m long pipes are easy to fit on the car trunk. For the assembly of the water supply system uses straight and angular couplings. It is desirable at the entrance to the main highway to install a coarse filter in the form of a separate unit or combined with a ball valve.

Summer water pipe from PND pipes is the easiest in assembly and maintenance. It is easily going without special tools and does not deteriorate in winter (only cranes for the winter remain completely open).

To quickly disconnect the entire water supply station from the central highway, a clutch with a cape nut, the so-called "American" is installed. Such a coupling allows you to connect and disconnect both rigid and flexible lines in necessary, not assigant threaded connections in other parts of the pipeline. Multiple issues will be required to fix the watering hose and a separate discharge for household needs with 1/2 ball valves. Polypropylene tubes are connected to metal elements by combined transition fittings, which at one end has a welding nest, and on the other - a thread.

To summarize water in the shower, pipes 20 mm are quite suitable, they are fastened with plastic clips with plastic clips with an interval of 1 m.

Almost all summer water pipe pipes are freely laid directly on the surface of the Earth. There is no need for special means of protecting pipes from temperature deformation and voltage.

Drain of water from all lines of summer water supply is organized as simple as possible and convenient. It is advisable to install standard tees with plug plugs in the lowest pipes.

How to prepare plastic pipes to assembling summer water pipes

If the relief of the cottage area is uneven, when pipes are wiring in some places of water supply, due to a small bending, an excessive voltage is created. To eliminate high pressure, it is sufficient to be a bit of a pipe using a construction hairdryer with a special nozzle.

When assembling the system, it is necessary to customize polypropylene tubes under the required length. For cutting plastic pipes with a cross section of up to 40 mm, special scissors are used. There are scissors for cutting pipes with a diameter of up to 75mm. But most often for plastic pipes 50 mm and the roller cutter is more used.

When working, the cutter does not require additional processing of the ends of unarmed pipes. If the volume of installation is small, it is quite possible to cut the plastic pipes with ordinary hacksaw for metal, electric jigsaw or "grinder".

Preparation of trenches for summer water supply

The next stage of the construction of the water supply - preparation of the trench. Its depth depends on the location of the pipes: for the lawn, 15-20 cm is enough, and 40-70 cm beds are started to dig from the water source, then all pipes are packed into the trench and securely combine each other. After laying and docking pipes, check the plumbing for leaks. You should not allow the fibers of the water supply in short areas due to possible water stagnation. After that, proceed to the connection of water treatment devices.

Water intake devices

If the pipeline is designed to supply water to a greenhouse, then cast iron or bronze valves and taps with letters are installed. Ball cranes are not recommended, as they are quite soon fail.

Water disposal assembly is the most complex device in the plumbing. It is equipped in a unheated room or on the street. The water treatment column is less common due to the complex installation and high cost.

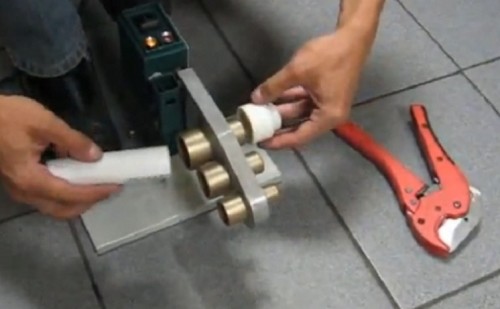

How the soldering iron is arranged for welding plastic pipes

There are solders of the domestic production of good quality and at a reasonable price, equipped with a comfortable metal suitcase, scissors for cutting pipes, tape measure and gloves. There are no less expensive modifications - without additional configuration and with fewer nozzles.

The welding machine-soldering iron for polypropylene and polyethylene pipes consists of three main parts:

- Soldering iron with a Tan (plate with heating element) and control unit (switches, temperature relays, indicators).

- Replaceable nozzles for heating pipes and fittings. They are fixed by bolts to the heating plate through special holes. Nozzles are made of aluminum alloy with anti-adhesive teflon coating and require neat and gentle conversion. It is forbidden to be purified by metal brushes and abrasive means to avoid damage to the Teflon surface.

- Stand for fixing the apparatus in the process of welding.

How to weld polypropylene pipes

Diffusion welding of polypropylene pipes occurs due to partial surface melting of the parts connected when heated using a welding machine. The operating temperature during polypropylene welding is 260 ° C. In order for the welding joint to be durable, the details must have the same properties. It is not recommended to weld pipes from different manufacturers.

Fittings and pipes of different brands are distinguished by the softening rate, tolerance for diameters. The welding process itself is not complicated and takes some time. You should accurately follow the time intervals allocated according to the instructions for each phase: heating - welding - cooling.

Both parts prepared for welding are simultaneously attached to the nozzle of the welding machine: the fitting is put on the nozzle of Dorn, and the pipe is inserted into the coupling nozzle.

It is impossible to rotate and dismiss the pipe and fitting during heating, so both parts try on to each other in advance and for convenience are marked with colored markers. The heating time is counted after completing the pipe and fitting on the nozzle.

At the end of the heating, the parts are removed from the nozzles and connect: the end of the pipe is inserted until it stops the fitting socket. The welding time is starting from the moment the pipe is connected to the fitting. The connected parts are fixed and kept motionless, not allowing displacement during the welding time indicated in the instructions.

It is forbidden to cool the parts with compressed air or cold water.

The final phase is cooling parts. During this period of time, it is impossible to load the connection to the complete cooling and restoring the mechanical strength of the parts.

After the cooling stage is completed, you begin welding the following connections or install the assembled node to the designated place. After testing the plumbing system, the ground is sprinkled or left on the surface.

Conclusions with cranes are installed throughout the site, which is attached to a single movement a piece of the hose of the required length. With the help of a variety of sprinkles, it is possible to simultaneously watered in several places at once.

Summer water pipeline service rules

Along with the undisputed advantages of the summer water supply, the ease and speed of assembly, efficiency, there are some drawbacks - for example, the need to drain water for the winter and observance of the linker to the place of connection. Otherwise, water will freeze in the pipes and the defect is formed part of the water supply system. For draining water at the lowest point of the system, a special valve mount. It is necessary to choose the right slope, otherwise the water pressure will be weak.

If the water pipe is ground, disassemble the design with subsequent storage indoor. It is necessary to periodically check the condition of the pipes and connecting elements and, if necessary, replace individual details.

With the arrangement of a permanent summer water pipeline, the pipes and hoses are placed in the ground, with the conclusion to the surface of the cranes and switches. There is no need to bury the design to a large depth. It is enough just to fall asleep the ground pipeline to ensure its safety and not create obstacles for walking.

What will be the summer water supply on the cottage - the simplest scheme of girlfriend or modern design with automatic control - each chooses himself. In any case, the arrangement of the water supply system in the country area will fully justify the applied efforts and the funds spent. If you rephrase the classics: water supply is not a luxury, but a means for watering. Thanks to the summer pipeline, water is supplied to the most distant corners of the garden, and then it will be possible to forget about heavy buckets and watering can be forgotten and vacated the time in a circle of family and friends.