Liquid nails: characteristics and selection Building materials

Build a durable, reliable and beautiful home or carry out repairs when changing the interior design in a cottage or an apartment is impossible without high-quality fasteners. You can give preference to the standard version - nails, but the procedure will be time consuming, the parts themselves will give an additional load on the surface, and not all materials can be combined with them without loss of attractiveness. It is for these reasons that it is better to choose a more perfect modern version of the connection of the canvas, profiles and modules - these are liquid nails.

Content

What is liquid nails?

This name is collective for a group of adhesive solutions. It was formed from the name of the company directly, which for the first time launched the production of such products - the American brand Liquid Nails.

In the world market there was such a kind of about 30 years ago, more precisely, in 1968, and immediately won the constant popularity of consumers, both professionals and those who seek to carry out a number of work on repair and construction in their own house. In the domestic market, liquid nails appeared only in the 90s of the last century, however, today the line of this product is represented by many manufacturers.

Important! Regardless of your professional skills, before glueing to liquid nails, be sure to read the instructions to comply with all the rules and ensure the maximum high level of clutch reliability.

Liquid nails: characteristics and dignity

All glue solutions of this category are characterized by excellent technical characteristics that are at the same time significant advantages of the material - this is:

- high strength - 15-80 kg / sq. Cm;

- excellent adhesion indicator;

- corrosion resistance;

- lack of adverse effects in the form of destruction of the fastened surface;

- ease of use;

- heat resistance and fire safety;

- fully "clean" process of fastening the necessary parts - without dust, dirt, noise;

- low temperatures resistance;

- most of the compositions are neutral, a unwitting smell;

- complete absence of components harmful to the human body;

- maximum rapid clutch of surfaces for a few seconds;

- great capabilities with respect to carrier load - one drop is sufficient to attach a part weighing 50 kg;

- good plasticity that allows you to glue even poorly adjacent surfaces to each other;

- economical consumption.

Important! The release of such adhesive is carried out in a standard form - a cylindrical cartridge with a capacity of 310 ml. The price of liquid nails varies depending on the manufacturer. But each of them guarantees the preservation of all the characteristics when using glue in the period of 1 year from the date of release. Therefore, before buying liquid nails, decide on the budget to choose the optimal brand.

What are liquid nails?

There are 2 main ways to classify liquid nails:

The appointment distinguishes adhesives of such species:

- Universal, the use of which is possible for almost any purpose.

- Special. Such compositions have clear recommendations regarding materials and details that can be consolidated with their help. In this group, for example, liquid nails are isolated for internal work, for the installation of polynesses, for heavy structures and modules, for wet rooms, to install mirrors, for mounting ceramic products.

Important! All features of the use of liquid nails are indicated in the glue instructions.

By component composition distinguish such types of liquid nails:

- Glue from synthetic rubber. In these solutions, an organic solvent and mineral fine filler is added. Such liquid nails are excellent for connecting different materials, including heavy and metal structures, and use in difficult operating conditions - high humidity, temperature drops, up to negative, etc.

Important! This group of adhesives and some disadvantages, which consist in a sharp smell, low, but still toxicity, and their complete unsuitability for connecting synthetic materials.

- Acrylic-based glue. These are water-soluble compositions that differ in environmental cleanliness and absolute harmlessness. Such liquid nails are used for lighter structures, including for fastening porous materials.

Important! As deficiencies, there is no possibility of using in frost and high humidity.

Where do liquid nails apply?

The areas of use of liquid nails are quite varied. With their help, you can solve many tasks that are quite problematic using traditional fasteners.

The most common options:

- installation of ceiling panel modules;

- installation of panels for walls from different materials;

- installation of plasterboard products;

- build structures from sawn timber, solid wood;

- connection of parts made of concrete, metal, plastic, textiles, glass, ceramics, polystyrene;

- installation of brick structures;

- installation of window sills, cornices, profiles, plinths.

Important! It is more clear to imagine how one-piece structures, formed using liquid nails, will help, help photos of finished works. They differ greater accuracy and aesthetic attractiveness than using conventional fasteners.

What to pay attention to when choosing?

In order for the expected result to correspond to such in reality, the prerequisite is the acquisition of a qualitative material of a suitable type. It's easy enough to do this if you adhere to simple recommendations:

- Specify the setting time of glue on the package, it can be extended up to 40 minutes.

- Check out the absence of calcium and chalk carbonate, as they worsen adhesion properties.

- Check out the absence of acetone and toluene in the mixture, as they cause a sharp unpleasant smell of glue, and besides harmful to humans.

- For work with ceramic tiles, give preference to quick-drying water-soluble adhesives, such as Solvent Free or Titanium WB-50. They are also resistant to small vibration and high humidity.

- To secure mirrors, choose those liquid nails that do not have corrosive substances, for example, liquid nails Mounting, LN-930 or Zigger 93.

- For the arrangement of the bathroom, they will suit those solutions that are distinguished by increased resistance to stable humidity, such as TUB SURROUND or Nail Power.

- All light profile panels are moldings, plinths, plumbing, using the compositions with a short grasp. These include Tigger Construction ADHESIVE and Solvent Free.

- For heavy parts, use liquid nails of special purpose - Zigger 99, moment Installation, high-strength Heavy Duty, LN 901.

Important! When performing work, be sure to note that the complete polymerization of almost all types of liquid nails is achieved between 12-24 hours.

How to use liquid nails?

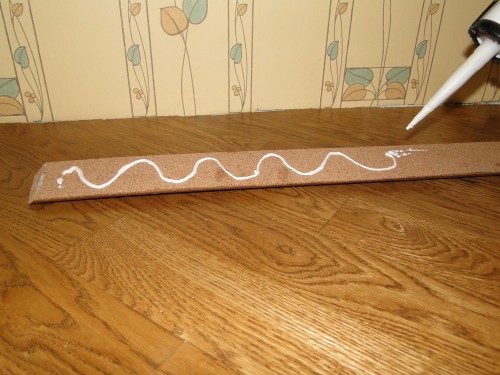

The technology of using liquid nails is quite simple and is available for development, even for those who do not have any construction skills. Particular ease of use of the adhesive is that it is easily dispensed and applied to the surface a small amount. Using even at home a special cartridge gun, which is mounted in the cartridge, allows you to completely avoid overspending at the same time secure the parts even in remote places.

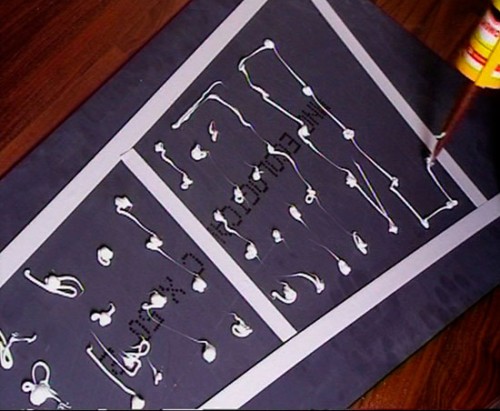

Bonding liquid nails - progress:

- Clean the base surface and the reverse side of the part itself.

- Degrease surface.

- Apply the dotted or wavy thin line of adhesive on one surface.

- Wait for 2 minutes.

- Connect the necessary elements.

- Wait for another 5-6 minutes.

- Repeatedly firmly press surface.

- If during operation, the unnecessary portion randomly treated to remove the time setting glue with a soft spatula or mineral spirits.

- If liquid nails have hardened, use to remove excess sand paper or a hard trowel.

Important! Note that, if necessary, you can adjust the position of the parts relative to each other over the next 10 minutes. Fully take high loads specified by the manufacturer, liquid nails are only on the expiration of the week.

How to use liquid nails - video instruction

Conclusion

The use of liquid nails really versatile and can significantly reduce construction time, simplify the process of bonding the different components, to achieve increase the aesthetic appeal due to their lack of additional holes and unsightly seams. Make sure this person, using the following planned work such glue, but be sure to pay heed to the selection and application of compliance technology. In this case, the result is you will certainly be pleased.