How to make a gazebo of polycarbonate with your own hands? Construction,Plot.

The gazebo is an excellent opportunity to relax in nature regardless of weather conditions. Nevertheless, its construction is a rather laborious process that stops many dacities. Solving this problem with a gazebo from polycarbonate. The material is easy to install, does not require much care and rather durable. In addition, the whole process of construction, from buying materials, to the first tea party under a canopy, takes from one to three days.

Content

Technical aspects of construction of polycarbonate gazebos

In order for the construction process to be as fast as possible and high-quality, it is necessary to compile an action plan. Include it will be the following steps:

- drawing plan arbor,

- choosing polycarbonate,

- choosing a framework of a frame

- floor arrangement

- installation of polycarbonate,

- decoration.

Also, you will need a certain set of tools:

- drill,

- passatia,

- gloves,

- screwdriver.

If the frame is planned welded - welding.

In addition, there are some practical advice on choosing space for the arbor and its arrangement.

- the gazebo should be located near the soda track,

- the gazebo should be given from garden plants,

- an ideal place - under the crown of wood,

- the playground under the arbor must be smooth

- it is not recommended to build a gazebo near the garage.

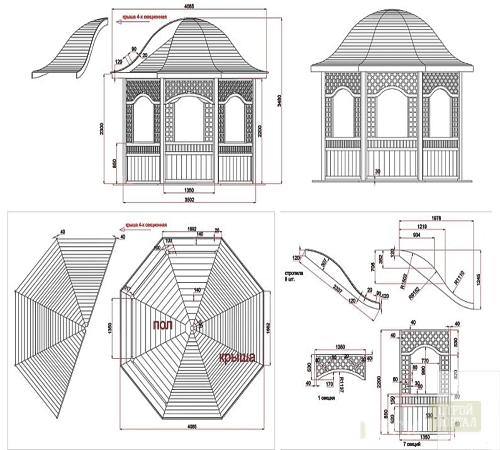

Drawing plan arbor

Polycarbonate is easy enough to take any shape, therefore it is one of the most sought-after building materials in landscape design. Arbors with its use are built from stone, wood, metal and forged structures. Select the appropriate option of the polycarbonate gazebo will help the photo.

With the wooden and stone bases, polycarbonate is used purely as roofing material. From the positive moments, a transparent roof, but such a construction is very costly and does not allow to create a really beautiful gazebo.

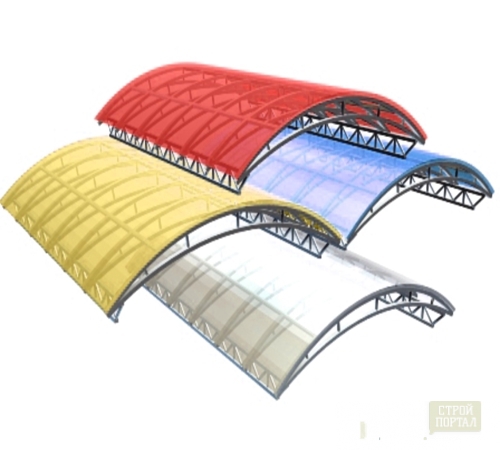

Metallic and forged frames are more often a polycarbonate. When creating an open-type gazebo, only the roof is mounted from polycarbonate, carrying columns are mounted from metal and decorated with various elements. But in such a gazebo it will not be cozy during the rain. Therefore, the most common version of the execution is arbors for a harsh type polycarbonate, when the end parts of the design are left open, and the rest is completely closed.

We choose polycarbonate

Polycarbonates are melting plastic products. According to its properties, they remotely resemble glass, but at the same time they have all the advantages of ordinary polymers. Polycarbonates are of different colors of shades and ways of visual design. But these characteristics do not affect the reliability and strength of products. When choosing a material must be clarified:

- stretching limit (at least 55 MPa),

- resizing under the influence of heat (no more than 0.3%),

- shock viscosity (at least 25 kJ / m 2),

- bending strength (at least 90 MPa),

- melting temperature (at least 130 0 Celsius)

- minimum operating temperature (no less -25 0 Celsius)

- noise absorption (at least 5 scent),

- light transmitting (at least 50%).

From these parameters, the direct depends on how much the durable will be your gazebo. Standards are indicated in accordance with the Russian Goste. The standards of the European Union and the United States are somewhat different, as a rule, in the most side.

Select the basis for the frame

The main work in the construction of a gazebo of polycarbonate with their own hands is the installation of a frame. Therefore, this issue is suitable as soon as possible. In general, they allocate:

- metal frame

- caught frame,

- block frame.

Metal design is the easiest way. For its manufacture, it is suitable:

- reinforcement

- pipes

- profiles

- corners.

The frame of the reinforcement is assembled by welding. Although this is the easiest way, it looks less effectively than others. In addition, to attach polycarbonate sheets will have to use wire. The holes in sheets will be the source of moisture penetration. As a result, such canopies and gazebos from polycarbonate will not protect against rain. In addition, the wet metal will constantly start rust, which will require additional effort and repair costs.

Pipes are more acceptable, as their bodies are enough for fastening sheets with screws. But externally, they, like fittings, look rather unsequently. Suitable for making gazebo for giving from polycarbonate in the presence of old water pipes or gas pipes.

Profiled pipes, on a row with corners are used most often. They look most attractive. Corners are used only if there is enough lateral carrier supports to fasten the sheet. If the support is needed in the middle, it is better to buy a profiled tube. Alternatively, the corner is cut with a grinder into two parts.

Forged frames are made to order either purchased in specialized stores. The price of the forging itself is high enough, so it's easier to buy a gazebo of polycarbonate in the ready-made form. At the same time, the sheets are better acquired independently and transfer the manufacturer. So you will protect yourself from fraudulent actions that are not uncommon among such firms.

Polycarbonate gazebos, the price of which is highest, are manufactured on a block principle. The system resembles a metal-plastic bag. The advantages of this option a lot:

- increased sound insulation

- conservation of heat

- attractive appearance.

The disadvantage is that it is quite difficult to produce a similar design.

Mount the floor

Construction work begins with floor arrangement. The total weight of the gazebo from polycarbonate is not great. Therefore, it is not necessary to fill the foundation. On the other hand, if the gazebo is on the ground, the swamp after the rain will definitely fall inside. Therefore, the pad is poured either by a thin layer of concrete (5-8 cm), or straight to the ground are pinched. More expensive option - wooden platform.

For its installation, small holes dig up and poured them with cement. Pits must be opposite each other. The height of the columns formed should be higher than the level of land. They are installed on wooden beams, which serve as the basis for the floor. Beams must be located apart from each other at a distance of no more than 50 cm. The floor is made either from OSB or from plywood or from the fender. In order for the platform to have a finished look, the end edges are closed with any moisture-resistant material (or dried with a cloth, the ends of which get to the ground).

Unusual version of the floor - sand. If there is a reservoir near the gazebos, it is really to create a feeling of relaxation to the sea. To do this, they dig a hole with a depth of 15 cm, 20 cm is wider than the diameter of the gazebo itself, and the sand falls asleep. More often use a small fraction, as it is more pleasant to the touch, but there is no practical difference. When choosing this option, it is advisable to install on the border of the borders. They will protect against swamps on the sand and sand in the ground.

Mount the gazebo

Arbors from metal and polycarbonate according to the installation method are similar to forged. The process consists of:

- frame assembly,

- its installation

- installations of polycarbonate sheets.

If the drawing of the construction in the hands, then the frame starts to collect directly at the place. Before the start of the assembly under the supporting elements of the structure, pits of a depth of 10-15 cm, which poured cement. This is necessary in order to securely fix the gazebo.

Mounted at the beginning of the bearing elements, then binders (if necessary). When assembling metal structures, it is preferable to use welding. Although it will make the design inseparable, but will significantly increase the strength.

The final stage is the fastening of sheets. Given that the polycarbonate is enough, it is easy to work with him. The drill of a smaller diameter than the screw, drills a hole through polycarbonate and metal profile. Next to it screws the screw. It is best to use roofing options with a rubberized hat. It is to protect against the flow. In addition, there are also special fastening systems for polycarbonate.

If you still decided to make a block option, you will have to work. The process looks like this:

- measurement,

- production of blocks,

- mounting.

Omnic work is necessary in order to understand which sizes will be blocks. They must be the same size, so that the gazebo is turned out to work in detail with the indication of all the dimensions.

Blocks are collected as ordinary wooden windows, but instead of glass, polycarbonate is inserted. This design is sufficiently heavy, so the reference beams are installed on the inside. In finished blocks, the sheet is inserted only on one side and start assembling. They are going to be together I screw to each other with wood screws. After the twist is made, insert the second sheet and lining fixators.

The finished design decorate either siding, or color. An easier option to order the manufacturer's company is already a ready-made plastic block system. The company's specialists will assemble it for 1-2 days depending on the size.

Deco

In order for such a gazeb to be cozy, it is necessary to competently come up with a design. The use of polycarbonate automatically determines the style - High-tech. Consequently, all the rest of the design will be performed in cold gray tones using various metal structures.

An adhesive gazebo from polycarbonate provides more space for creativity. Metal assumes strict design and minimalism. But in any case, in the gazebo, at least there should be at least chairs or a bench, but also the table is also better.

Cheap, but in this case the winch is plastic. Plastic garden furniture will surprise with its diversity even the most vivid imagination. More expensive solution - glass. But the use of glass elements involves compliance with elementary safety rules.