How to make waterproofing foundation Insulation,Construction

There are several ways to make the foundation waterproofing with their own hands. They are fundamentally different from each other, so for a start, it is necessary to determine with the type of foundation, as well as indicators of groundwater and atmospheric precipitation. Depending on this, you can move to the selection of materials.

Content

Foundation Waterproofing Materials

Depending on the type of foundation and method of waterproofing, apply:

- ruberoid

- crushed

- clay

- concrete,

- special waterproofing impregnations.

Each of the options has both their advantages and disadvantages.

- Ruberoid serves overlap between the foundation and the basis of the house. He flawlessly protects against dampness, but does not allow the walls to "breathe". This type of waterproofing is suitable for a ribbon or pole foundation.

- Another option is the bituminous waterproofing of the foundation. This material is attractive to its low cost and ease of use. But, as in the case of rubberoid, the resin does not allow to penetrate oxygen. As a result, the appearance of mold and unpleasant odor is possible.

- You can use more expensive analogue - bitumen mastic for waterproofing the foundation. It is also easy to use, but promotes air outflow.

- Crushed stone or gravel use to create drainage under the foundation. The stone crumb is mixed with sand and evenly distributed in the basement channel. This is relevant if the house is only in the planning process.

- In the event that the waterproofing is already necessary for the finished foundation, it is worth thinking about more modern ways. The penetrating waterproofing of the foundation allows you to treat the foundation using chemical impregnations and make it moisture-repellent.

Types of waterproofing

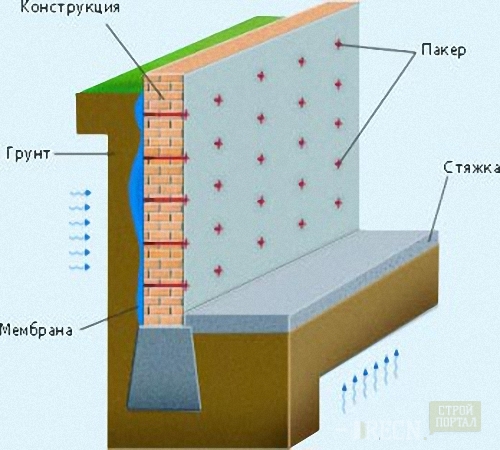

It is customary to distinguish the horizontal and vertical waterproofing of the foundation.

- The first way is cheaper and fast. It does not require any additional skills or special inventory. But horizontal waterproofing can provide protection against moisture only in regions with a low or insignificant level of atmospheric precipitation.

- Vertical waterproofing allows you to fully protect the foundation from the destructive impact of moisture. The cost of work is much more expensive, but also the service life can be extended by 10-15 years.

In addition, in the regions with cold snowy winters without vertical waterproofing can not do. The snow will constantly melting and drink the foundation of moisture. As a result, the walls of the house will begin to wet and collapse. To dry out a belt foundation, you need 4-5 months of dry weather, for monolithic - at least a year.

The process can be divided into two stages. Preparatory work will include the creation of a drainage system and stacking the foundation itself. The second stage is direct waterproofing.

Waterproofing of pillars and tape foundations

Waterproofing of the ribbon foundation begins with digging the channel under the foundation.

- The depth should be at least 30 cm for a single-storey house, 50 cm - for a two-story.

- For each subsequent floor you need to add 50 cm.

- The width of the channel must be at least 40 cm, but not more than 1 m.

For drainage, you can use clayjit or crushed sand. This is done so that the water is not delayed under the foundation and the house did not ask. In addition, it increases the service life of the foundation.

The next stage is fill.

- A concrete belt is made around the perimeter of the house.

- The height above the surface of the earth should be at least 10 cm.

- In regions with abundant atmospheric sediments, a higher foundation should be made.

- Its upper edge should always be above the water level or snow.

- It should be remembered that even the most ideal waterproofing will not be able to protect against constant moisture.

Ruberoid falls over the foundation. It allows you to separate the foundation of the house and secure it from moisture ingress, even if the foundation itself wuresward.

Another version of the horizontal waterproofing of the foundation is the use of special polyethylene tapes. They interact well with the solution and allow you to create a monolithic design, but their cost is higher.

To increase operational properties, you can perform vertical waterproofing with bitumen solutions. But in this case, this is not necessary.

All these rules are valid for pillars. Since it differs from the belt only by consisting of separate colons, located under all angles of the house. Pillar foundation is used in regions with high humidity.

Waterproofing of monolithic and floating foundations

Waterproofing of the monolithic foundation is a more laborious process. First, such a foundation is located under the entire area of \u200b\u200bthe house. Secondly, it requires not only the creation of a drainage system, but also an additional ribbon waterproofing.

Ribbon waterproofing involves the creation of additional trenches around the foundation.

- At a distance of 50 cm from the base, you need to dig a trench with a depth and width of 30 cm.

- The trench falls asleep in several layers. The first is clay, the second is crushed stone, the third is a concrete solution.

- This additional rigid ring will strengthen the foundation and will avoid unnecessary moisture from the soil.

The method is suitable for already built foundations.

Given the fact that the monolithic base is very massive and in the case of wetting will dry for a long time, we should use liquid waterproofing of the foundation. Bituminous mastic or chemical impregnations will allow the maximum to protect the moisture. They retain natural ventilation and protect against fungus.

For example, the coating waterproofing of the foundation creates a thin layer on the surface, a thickness of 1 mm, which has absorbent properties. Thus, even moisture from the air settles on the surface of the foundation in the form of dew.

These ways are relevant for the floating foundation, the exception that the belt of rigidity should be made at a distance of at least 1 meter from the base.

Thus, the foundation waterproofing device depends on many factors. It is easier to plan this work before the construction of construction. But even if problems with the foundation began after the end of all works, modern building materials make it possible to solve this problem.