How to install a circulation pump in the heating system with their own hands Useful advice

An important component of an individual heating system is a circulation pump. This arrangement is necessary to enhance the efficiency and coolant temperature control. Set the circulation pump for heating their own hands - a task feasible for everyone. Only need to learn some preliminary information on the pump and on the rules of its installation.

Content

- Basic information about the circulation pumps

- Terms circulation pump in the heating system installation

- How to put a circulator with their hands in a forced and natural circulation systems

- How to connect the circulation pump to the power supply

- Terms entered the circulation pump in operation

- pump control

- Repair of the circulating pump with their own hands

Basic information about the circulation pumps

Two types of such devices:

- with "dry" rotor;

- with "wet" rotor.

The circulation pump "dry" rotor

The first distinguished by great efficiency and noise level. Pumps with "wet" rotor have less efficiency (not more than 50%), but they are able to operate for many years without maintenance (in contrast to pumps with "dry" rotor). For home heating system circulating pump with their own hands is recommended to put a "wet" rotor.

The circulation pump with "wet" rotor

Terms circulation pump in the heating system installation

- The place of installation of the pump is determined on the heat pipe site immediately after the heating boiler. Installation of the pump both on the "feed" and on the "return" is allowed. The unit easily withstands high (up to 115 ° C) temperature.

- The place of installation is not regulated from the point of view of hydraulics: it does not affect the operation of the heating devices.

- It is important to correct orientation of the rotor when installing the system and tightness of the compounds. The rotor must stand horizontally.

- The circulation pump must be correctly installed: the installation with hands is performed in such a way that the arrow on the unit of the unit coincides with the direction of movement of the coolant.

- In the event that the pump must be installed on a vertical pipe, choose a more powerful model to compensate for a 30% drop in power.

- For a multi-tiered heating system or consisting of several branches, it is planned to install a circulation pump with hands in each of the branches. In this case, the first rule should be observed (see above) to maintain the ability to adjust the temperature in each room and save.

- The rate of leakage of the coolant on the upper tier of the system is set to less than on the bottom. This is explained by the fact that warm air rises up, and therefore in this zone there is no need to spend excess energy and heating means.

Installing pumps in each of the heating system branches

How to put a circulation pump with your own hands in systems with forced and natural circulation

There is a certain difference in the technologies for mounting the circulation pump for various heating systems.

Features of forced circulation systems

- The pump must be in the system.

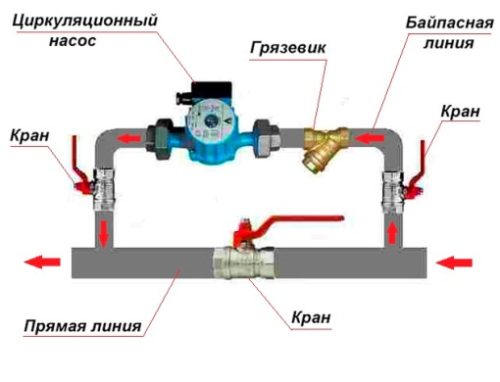

- The pump in the direction of movement of the coolant is set by a mesh coarse filter. His task is to detain sand particles or other mechanical impurities to avoid engine damage.

- In order for the pump can, if necessary, dismantle, ball valves are installed before entering and after accessing pipes. This measure allows the removal of the unit without draining the coolant.

Filter rough cleaning

Installation of the pump in the system with natural circulation

Circulation pump with bypass in the system

- In order to ensure the health of the heating system in the event of a pump output, set a special jumper called bypass.

- Bypass must be equipped with a ball valve to cut off the jumper when the system is enforced.

- When the pump is disconnected, the bypass valve is in open mode, and the inlet and output cranes are closed. In this case, the heating system works on a gravitational principle.

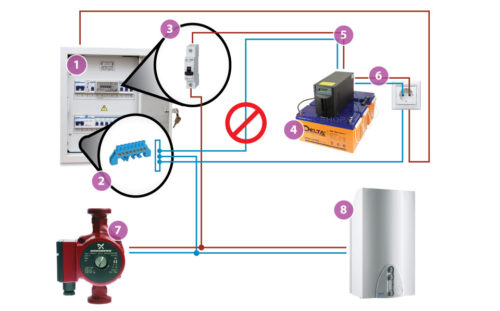

How to connect a circulation pump to power supply

Circulation pumps are connected to a 130 volt alternating voltage consumer power supply. The following rules must be followed.

- A separate three-in-room cable (with grounding residential) is laid to the pump from the switchboard. In the switchboard connection is carried out to a separate protective bipolar machine.

- In the event that the pump is equipped with a feed wire, the connection is implemented using a three-contact plug and a socket.

- The pump without cable is connected directly to the terminal block. It is important to observe polarity: phase contact is denoted by the symbol "L", zero - "n", grounding - a special sign "ꓕ".

- For grounding, a wire with yellow or yellow-green isolation is used, for the "phase" - with brown or red, for "zero" - with blue or white. There are also cables of foreign manufacturers with another color labeling.

- The uninterruptible power supply (UPS) source for the circulation pump is installed in the connection scheme to ensure uninterrupted operation of the heating system. UPS can be replaced with batteries and voltage stabilizer.

Circulating pump circuit to the power supply

Rules for entering the circulation pump commissioning

The effectiveness and duration of the service life of the aggregate depend on the observance of a number of conditions set out below. In addition, it is necessary to follow safety regulations.

- Before running the pump, water should be flooded into the housing and suction piping. Operation of the pump in dry stroke mode can lead to its failure.

- The power supply wire of the circulation pump must be connected to the Uzo (protective disconnection device). This will avoid electric shock in case of insulation damage.

- The electrical outlet to which the pump is connected must be installed so that the ability to enter it moisture is completely excluded.

- Before connecting the unit to the supply network, it is necessary to attach to the corresponding grounding base terminal.

- It is important that the power supply voltage corresponds to the required values. A deviation is allowed no more than 10%. Otherwise, the engine resource is reduced.

- On the supply pipe (before the pump), a coarse cleaning filter is set to protect the impeller and rotor from mechanical damage. This is especially important if the level of contamination of the coolant exceeds 50 mg / l, and the size of mechanical impurities is greater than 0.1 mm.

- The room in which the pump is installed must be well ventilated. The temperature in it should not exceed + 40 ° C.

- Foreign liquids (acids, alkalis, detergents, fuel) should not fall into the coolant.

- The installation site of the pump is chosen in such a way that access to repair and maintenance of the unit is provided.

- It is impossible to avoid the nominal volume of the pumped coolant.

- In the case of the pump preservation, the whole liquid must be merged. It is recommended to include the unit for half an hour each month to prevent corrosion of metal parts.

- With the initial inclusion of the pump or when it is commissioned, after a long break, it is necessary to make sure that there are no extraneous noise and vibrations. The quality of the tightening of the screw connections, contacts in the terminal box and the tightness of the connections are checked.

Location of the elements of the heating system

Pump control

The control consists in setting the equipment in such a way that when the temperature of the coolant is reduced to a certain level, the pump has occurred, and when increasing is shutdown.

The main node of such automation can be the thermostat. The temperature control of the circulating pump on the temperature is reduced to the installation of the thermostat in a certain place of the room, away from the heating devices, from the windows and doors. The signals are transmitted to the executive mechanism over the cable. When the critical temperature is reached, the thermostat includes or turns off the pump.

Thermal sensor

Important: microclimate depends on the choice of the installation site of the thermostat, and in different rooms it can be very different. To avoid this, it is recommended for each circulation pump (if several of them) use a separate thermostat.

Repair of the circulation pump with their own hands

Some model faults of the unit can be eliminated independently. Your attention is to repair the circulation pump "Wilo" with your own hands (algorithm of action).

If the nanos buzzes, but the rotor does not rotate

Turn off the power, we are convinced that the pump housing is filled with a coolant, perform a re-inclusion. If the rotor fails to be renob, it is necessary to do the following.

- Turn off the pump power.

- We overlap the ball valves at the input and output, open the karan bypass (if it is provided with the design).

- Unscrew the plug holes, drain the whole liquid.

- Remove the screws of fasteners, dismantle the pump from the system.

- Remove the engine from protective casing.

- We inspect the pump details for the presence of foreign objects. We remove those if they are present.

- Putting into a notch on the Rotor shaft, turn it out several times to make sure that there are no more interference to the moving parts.

- We collect the pump in the reverse order, connect to the power grid and run.

Circulating pump in disassembled state

There is no hum and no rotation

- We check the presence of voltage in the power outlet and make sure that its value corresponds to the desired one.

- Check the quality of contacts in the terminal box, tighten the screws (for this, at first we will first turn off the power supply "machine").

- In the presence of a fuse, we check its integrity and, if necessary, change it.

When stopping the pump after starting work

The reason for this can be sediments of salts and lime around the rotor. It is necessary to disassemble the pump and the mechanically clean it. At the same time, it is important not to damage the windings of the stator and the rotor.

Strong vibration during operation

The reason is the wear or failure of the impeller bearing. To eliminate the fault, the bearing should be replaced.

Foreign noise

Cause - air in the system. To eliminate a malfunction, do the following.

- We define the upper point of the heating system pipeline.

- Install an automatic air removal unit.

- If necessary, increase the level of pressure in the system by increasing the amount of coolant.

What to do if the pump is very hot during work? How in this case the circulation pump is repaired - video with specialist comments.