What laminate is better to choose Floors

Currently, the laminate is a worthy alternative to an expensive parquet. The operational period of some laminate models exceeds 15-20 years, and the variety of color gamut allows you to choose a lamella, ideally combined with any style solution. However, the qualitative characteristics of the laminate depend on the set of factors, so most people come to the store simply do not know how to choose a laminate for the floor of one or another type of room.

Content

Laminate structure

The laminate samples presented in the stores, which are produced by various manufacturers may differ in both their structure and materials used in the production process. In addition, the variety of a wide model range causes a lot of issues, including the most important role is played by the only question - how to choose the laminate.

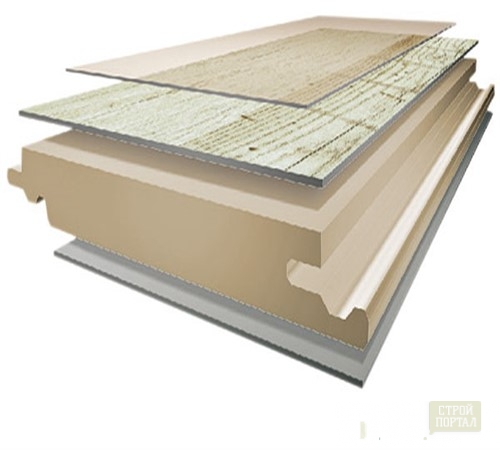

In general, the laminate panel is represented as a multilayer structure, including the layers of the following order:

- stabilizing - smoothes the unevenness of the floor, and also provides noise and thermal insulation. In a different way, this layer is referred to as the substrate and is present only in some, the most expensive, models;

- insulating - prevents the penetration of moisture into the upper layers of the panel, as well as its warping during operation due to high humidity. As insulating material, kraft-paper phenolic resins are used;

- carrying - characterizes the strength of the product. The main component of the laminate panel is the XDF or MDF plate, which is equipped with a lock compound necessary for laying the laminate without the use of adhesive composition;

- decorative - allows you to choose the desired color, the drawing, harmoniously combined with the interior where styling will be made. A certain decor is applied on paper, which is subsequently soaked with water-repellent compositions;

- protective - Provides resistance to abrasion, shocks and other mechanical damage. The materials for the design of the protective layer are acrylic or melamine resins.

Each row of laminate has certain features and functional purposes. In this case, the characteristics inherent in a separate layer affect the quality of the entire laminate panel.

Methods for determining the quality of the floor covering

Before proceeding with a detailed study of the technical characteristics of the floor covering, you first need to figure out how to choose a high-quality laminate, while taking the lamellas of dubious production.

The factors testifying to the good quality of the goods include:

- No sharp smell. It is permissible if the laminate exudes the smell of wood sawdust, but not acetone, glue and other chemistry.

- The presence on the lamella of the manufacturer marking. As a rule, the lack of marking indicates a violation of the laminate manufacturing process, which will definitely affect a short operational period.

- Individuality of the decor on the panels imitating a wooden surface. In nature, it is impossible to find condensed trees with a pattern identical on a cut. In this regard, the well-known manufacturers try to produce laminate in such a way that the repeatability of the figure has occurred not more than 1-2 lamellas per 100 pcs.

- Price. A high-quality floor covering of a well-known manufacturer cannot be implemented at a low price. The inverse situation is developing if the laminate is a good fake under a well-known brand or produced in violation of the technological process. In any case, a cheap laminate does not differ a long service life.

In addition to the above methods, the characteristic of high-quality laminate is the index of moisture resistance, ideally not exceeding 18%. However, to verify this indicator, you will have to purchase the packaging of the laminate you like, cut off a small piece of a piece and omitted into a container with water for 8 hours. In this case, the water should be room temperature. If, after the time of laminate, for example, a thickness of 10 mm will increase to 12 mm, it is unlikely that the remaining properties of the laminate from the acquired batch will be consistent with the data claimed by the manufacturer.

Of course, the considered ways about how to choose a good laminate are pretty conditional. However, after identifying the inconsistency of the closed laminate, at least one point, it is worth paying attention to the products of another manufacturer. If there are no deviations, you can safely move forward, alternating with the main characteristics of the laminate.

Laminate selection criteria

The main operational qualities of the floor covering are under the influence of a number of indicators. Analysis of the most significant properties of the laminate will help determine which laminate it is better to choose from the most liked models.

Resistance to abrasion

The wear resistance of the laminate is characterized by affiliate class: 21-23, 31-33. At the same time, the first digit of the marking corresponds to the type of room (2 - for use in everyday life, 3 - for use in the commercial plan organizations). The second digit indicates the intensity of movement along the flooring (1 - relatively small permeability, 3 is high).

The wear resistance class laminate is assigned on the basis of data obtained as a result of a tab test. The essence of the test is to accommodate the grinders on the laminate panel from a specific batch of goods, followed by its grinding before the formation of visible damage. During the experiment, the number of revolutions produced by the abrasive circle is calculated, on the basis of which the gradability indicator is assigned to laminate. So, 21-22 Class is characterized by the number of revolutions vary in the range of 7000-11000, 22-23 class corresponds to 11000-15000 revolutions. At the same time, the number of turnover of the most wear-resistant 33 class reaches 20,000 and higher.

Thus, doubting what to choose a laminate (23 or 31 class), it is still better to stop for 31, especially when laying a laminate in the corridor or in the kitchen, where the intensity of movement along the floor covering is quite high. However, it is worth considering that the cost of commercial laminate will be an order of magnitude higher than the household.

Resistance to mechanical damage

Impact resistance, along with the wear resistance of the laminate, largely depends on the materials used to create a coating and thickness of the protective layer, varying in the range of 0.2-0.6 mm. Thus, acrylic order resins are characterized by higher strength than melamine. In this case, the increase in strength indicators contributes to the impurities of the corundum particles and aluminum dioxide, additionally introduced into the resin. Special strength to the protective layer also gives the irradiation of the surface with electronic beams. However, this technique is applicable only to expensive variants of the laminate.

Resistance to scratches has the designation "AU" with a number from 1-5. Accordingly, the higher the digit, the greater resistance to mechanical damage and strength laminate has.

Laminate thickness

The strength, as well as the sound-absorbing properties of the laminate, are determined by the panel thickness and the method of its production. In addition, in the manufacture of laminate, the HDF-stove is used by European manufacturers. At the same time, Russian manufacturers often use the MDF slab, inferior to HDF according to the density degree and some operational indicators. In this case, the thickness of the laminate produced regardless of the type of plate varies from 6-12 mm. However, the smaller the thickness and density of the plate, the less durability they have panels.

Method for the production of laminate

Based on the production technology, the laminate produced from the HDF plate is divided into 3 types:

- HPL - high pressure laminate. In the process of production, the protective layer, under the influence of high pressure and temperature, is first compressed with a decorative layer, and then glued to the stove. From the Point side of the HDF-slab, the substrate is attached, after which the finished panel is re-crushing using flat presses, but under high pressure. HPL laminate is characterized by high operational properties, however, due to high cost, it is practically not in demand.

- CPL - laminate produced in a continuous technological process. The manufacture of laminate is carried out using lower pressure ribbon presses. The qualitative characteristics of the laminate of such production are somewhat inferior in terms of high-pressure laminate, including on a price basis, reducing consumer demand.

- DPL - direct pressing laminate. The options discussed above are characterized by speed and ease of manufacture, as well as an acceptable cost, as a result of which is quite high demand. The essence of production consists in simultaneously pressing all layers of laminate under the influence of high temperatures and pressure.

In the production process, all stoves, regardless of the species, are processed by special moisture-resistant compositions, antiseptics, etc., thereby increasing the indicator of their moisture resistance and service life.

Thus, before you are interested in how to choose a laminate for an apartment, it is necessary to pre-decide on the sum of money that is planned to be spent on the acquisition of laminate.

Method of installation

Based on the laying method, 2 types of laminate are distinguished:

1. Adhesive. Laying of laminate panels is performed by gluing them with ends with the help of waterproof adhesive composition. The coating laid in such a method forms a solid surface, characterized:

- high strength;

- minimal moisture effects;

- duration of operation;

- low cost.

However, before choosing a glue type laminate, it is worth weighing the flaws inherent in it:

- the inability to replace the damaged panel;

- cannot be used with a warm floor system;

- additional installation costs;

- labor complexity;

- completeness of installation, requiring the involvement of specialists.

2. The lock from the adhesive laminate is distinguished by the presence of connecting elements on all sides of the panel. In this case, the quality of the lock joint is the higher, the thickness of the layer.

Pluses of the Castle Connection:

- the ability to replace the damaged section of the coating;

- ease of installation / dismantling of laminate;

- speed and simplicity laying.

Minuses:

- exposure to the joints of moisture;

- shorter service life;

- high price.

Minimize disadvantages will help the processing of joints with water-repellent compositions.

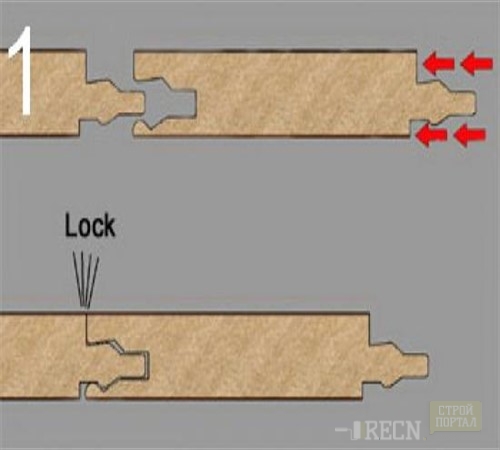

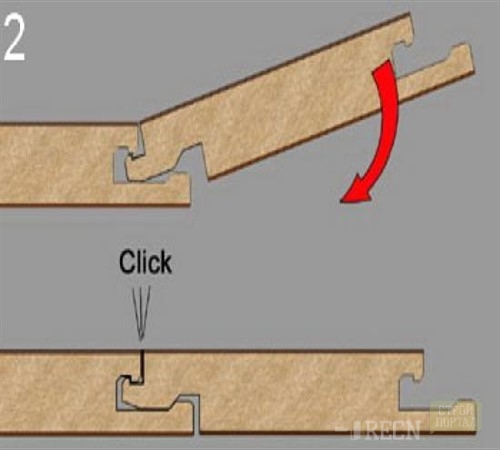

Laminate can be equipped with the following types of locks:

- Lok. The connection of the lamellae is carried out by drivening one panel to another by means of a wooden image, since the laminate of this type is equipped with a "Schip-groove" lock. The main disadvantage of laminate with the LOK system is the formation of gaps between the joints of the panels, which occurs after the expiration of the short life due to the inevitable loads on the coating. However, laminate with the LOK lock is much cheaper than the panels equipped with the Clik system.

- Clik. The connection of the panels occurs by snapping locks. In this case, one panel relative to the other should be at an angle of 45 °. A distinctive feature of laying a laminate, equipped with Clik-locks is the lack of discrepancies of the seams during the operational period, as well as the possibility of laying on the surface having irregularities up to 3 mm.

Based on the foregoing, before choosing a house laminate with a lock connection, you should ensure the quality and identity of the lock on all panels, since different manufacturers they may differ. In addition, the panels with Lok-locks, though they are cheaper, but for their laying, an ideal reason is required.

Manufacturer

Currently, laminate production is carried out in many countries, including Belgium, Germany, France, China, Russia, etc. At the same time, seeing a wide range of laminate of various manufacturers in the store, a reasonable question immediately arises, and the laminate of which firm can be selected so that it satisfies all the necessary criteria for wear resistance, strength, duration of operation, and other important indicators.

The fact is that the laminate of a particular manufacturer has its advantages and disadvantages, so it is necessary to solve the laminate of which manufacturer, it is necessary on the basis of the conditions for future operation.

For example, QUICK-STEP laminate products produced in Russia and Belgium differs in high quality, strength and unique design. However, a small selection of color gamut and price are the main shortcomings of the Quick-Step panels.

HDM laminate German production is characterized by excellent performance. However, the glossy surface of the HDM panels requires careful care, since any minor scratches or barefoot prints will spoil all the aesthetics of the coating.

Thus, what kind of laminate company it is better to choose - the case is a purely personal character, depending both from the necessary characteristics and the presence of a sum of money.

How to choose a color of laminate?

The color gamut of laminate should be purchased, guided by the following rules:

In small rooms, it is better to use bright shades. At the same time, in places of high passability it is worth avoiding laying of light laminate, since any inevitable contamination will immediately rush into the eyes.

For spacious premises, the laminate of dark shades will be suitable, subject to the presence of light tones in the furniture.

Laminate and interior doors, on the contrary, must be in the same color scheme. However, the coating must be chosen by 1-2 tones lighter than the doors, otherwise these finish items simply merge, instead of harmoniously complement each other.

If the apartment is small, then it is not necessary for each room to acquire a laminate, characterized by color and pattern. Otherwise, it will contribute to a visual decrease in space, because there will be a breakdown and so small premises to even lower zones.

So, before you determine how the color of the laminate is to choose, it is necessary to see how the desired shade will approach the established interior solution.

Thus, the choice of laminate is a rather complex occupation, which requires maximum care and possession of the necessary information, in order not to be in a short time before choosing a new laminate due to, for example, a small amount spilled onto the water coating.

And in conclusion, how to choose a laminate - video See below: