Pakle Linen - Features of wrecking on threads Useful advice

In everyday life sometimes there is a need for small repair, where the carving requires winding. It may be plumbing, radiators, and it means to learn how to use the passage, sooner or later it has to any owner in the house. Water pipes are metallic (galvanized or iron), plastic, metal-plastic and kapron (are used for launching underground). Each type has adapters to connect other pipes, about such docks and will be speech. It is a hermetically to connect pipes and other elements of the water supply, called "Packing". For example, we need to spoke two pipes at an angle of 90 ° with a clutch that winds on their ends with thread. The coupling consists of inner thread (mothers) and outer turns (dads). It will be not enough to twist them: for the correct connection it is necessary to take the threads.

Content

Linen Pacle: Features

Plumbing palable is a fibrous material that is used to seal the thread. This is a completely natural product obtained from the primary processing of homogeneous, thin, long fiber flax, which is extracted from the stalk of the plant.

The scope of the package is very wide. Depending on the production technology, it happens tape, construction, jut and sanitary. Construction package is a reliable way to insulate almost any connections. It uses completely spilled short fibers of flax, and it comes with bales. This material is intended for construction work on the sealing of seams, laying and insulation of log cabins. Being natural, Lyon is especially valued among those who build wooden houses. If the construction package comes in rolls of a certain width, then it is called the tape. Pacle Ribbon Linen is a potent material with a thickness of up to 1 cm. It is used for sealing seams and emptiness in the cuts, launching the crowns.

What are used to boost? The classic option is the good old flax (it is also called a panel or hemp), fum-tape, anaerobic sealants and polyamide thread tense.

About what is better to use, disputes are underway for many years, but the unambiguous answer is not found. The fact is that the material is selected depending on the type of work and can be interchangeable and complement.

Let's talk about the advantages of flax for plumbing work:

- the main "plus" pack of linen - its price is cheaper than any other material;

- it is economically spent;

- its thin fibers are highly durable;

- with the correct winding, it is suitable for any type of work with any compounds, including for sealing pig-iron and ceramic pipes;

- lyon can swell, absorbing the possible moisture, thereby hermetically overlapping the path to the leakage;

- high mechanical stability of the material allows you to make a fit of plumbing: without loss of hermetic properties, you can unscrew the connection to the half-turn or by a whole turnover.

The disadvantages of packles include such aspects:

- since flax is an organic matter, it has a property to rot under the influence of moisture and air, which fall into it, for example, with preventive inspections. For this, the package is always accompanied by an additional material that prevents concrete processes (sealing paste, solidol, oil paint, lithol and others);

- often it is required to prepare thread;

- too thick layer of material can lead to cracking of compounds, especially from bronze and brass;

- this is a seal that requires knowledge of the rules of winding. According to the Nativity, nothing is possible;

- related materials in combination with flax may make it difficult to disassemble, for example, oil paint and silicone can make the dismantling process is impossible;

- lyon is not suitable for use where the temperature reaches 90 ° C. In such places, it is "welded" over time and loses her sealing properties;

- if we are dealing with steel, then non-compliance with winding technology may even lead to thread corrosion.

How to choose flax?

The main thing is to pay attention to the quality of the packle before you buy it: flax should be sold, not a tight-knitted pigtail or bay, there is a light color, not to have impurities, garbage and lumps. There is also a package, laid in the form of a mock of threads, from whose middle, you can pull out the finished strand. The last option is somewhat more expensive than the rest. Be sure to note that the panel is not too coarse and did not have an unpleasant smell.

In addition to flax, we purchase additional material. It can be the "Multipact" sealing paste, "Unipacle" or "GreenPasta", which serve so that the panel does not spoil, did not burn under the action of temperatures and succumbed to dismantling. The contents of the Tube "Unipaca" is a light gray low-drying mass based on paraffin oil with an admixture of natural minerals.

If flax is not handled, the tightness of the connection will be short-lived. In addition, the use of paste allows you to slightly adjust twisting power.

It is strictly recommended to use silicone sealant in contact with the metal, as it contains acetic acid that accelerates the oxidation process, and, consequently, corrosion of the metal. Use neutral sealants. Different cars are suitable, or intended to eliminate leaks of water, oil and other liquids.

How to wind the pass on a new thread?

Before starting work, we prepare the turns. Today, many manufacturers produce fittings with a thread having notches, that is, specially intended for winding flax. The fact is that on a smooth thread during installation, flax will slip, knocking on the block, and the sealing process will be broken.

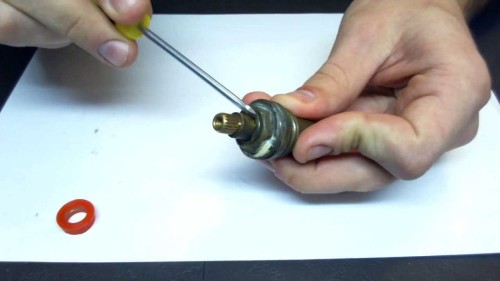

- In order for the fibers to be cling to, it should be jar on the turns. It is possible to apply them with a supfyl, a file, with a metal knife, with the help of a passage or a plumbing key, clasping the threads and lightly shifting. The main thing is to achieve light roughness on the turns.

- Now we separate one strand from flax pigtails. Try to capture so many fibers so that the winding is not too thin, neither too thick. It is believed that its thickness should be as one, maximum - two matches. If you have noticed lumps, minor villi, they need to be removed.

- How to impose - the case is individual. Someone twists Lyon in the harness, someone will braid it into a weak pigtail, someone puts it, a lot of masturbation, as it is, strand.

- The procedure for applying additional material can also be different: you can lubricate the threads, clean with its fibers, and then apply another layer; You can pre-impregnate the fibers of the packley, after which it is to cut them. Both options are correct.

Someone recommends winding strands along the thread, someone against, there is no single rule here. - The end of the strands clamp the finger outside the turns, making the first turn of the cross, to secure the pass.

- Then, as much as possible, without making lumens, the turn to the turn, we wake up flax.

Such a nuance: if you connect, for example, a steel coupling and an iron pipe, then the overaffect of flax will be simply squeezed out of fitting, due to its power. Brass compounds, especially modern production, and strong pressure simply burst. - We take a small amount of sanitary paste or other sealing material and rotational movements distribute around the wincised flax. We try to work careful.

- The second end is glued closer to the edge of the thread with the concomitant material.

- Before twisting, be sure to check whether the hole is clogged by the pipe.

- Spin with moderate effort. If the nut goes too easy, then there were little flax. When properly completed, the flax should not get out and around the connection should be pure.

Tip: For gas connections, it is not recommended to use an organic pass in combination with silicone, since under the influence of gas these materials are destroyed. Here will be the most appropriate use of fum-ribbons.

How to wind the passage to products from ecoplasty?

Like brass thread, plastic also tends to burst. Therefore, the main thing is not to overdo it. Before nothing, connect both fittings by counting the number of revolutions. Then you evenly wound the flax, turning it with an additional material, and connect the fittings. If there were 5 "frightened" revolutions, then take about 4.5 revolutions - you do not need to reach the end. Note: In this case, it is more expedient to use a packing paste instead of the sealant.

If when tightening you feel that it goes very tight, disassemble and wound fewer pacles.

How to work with old fitting?

If the package gave flow or it is necessary to dismantle the connection for other reasons, after developing inspecting the thread. Moms are spent on the turns of the knife with a knife or sewing, removing the entire accumulated garbage.

The contents of the "Pope" also smear the knife, cutting off the remnants of the packle together with the sealing agent. Metal brush clean the coil before the appearance of shine. It eliminates the dirt, rust and remnants of sealant in the most hard-to-reach places. If the existent thread is damaged, it will be useful will drive it on the "dad" with a thread-cutting tool, and on the "mother" knife with a tip.

Next, the process of the packing continues under the specified scheme.