Roof cover rubberoid with their own hands Construction,Building materials

During the construction of the roof of a residential building, it is always necessary to use only high-quality and durable materials so that the problems of major repairs are not worried about many years. Roofing pie not only protects the inner space of the house from precipitation, but also does not give precious heat outward, so the laying of each of its layer requires attention. Lastly, the atmospheric-resistant roofing material is mounted, which protects well from weather phenomena and at the same time attractively looks from the side. Ruberoid is one of the most economical options, and in this article we will discuss in detail the technology of covering the roof of the roof Ruberoid.

Content

How to choose a roof rubberoid

Initially, runneroid was used to protect the roof of temporary construction objects, warehouses, garages and other technical facilities. Time test showed that with proper laying this material can be stopped much longer than the temporary object should stand. Compliance with installation technology and timely service prolongs the service life of the roof from the rubberoid up to 15 years.

The material itself is produced and sold in rolls. Its direct appointment is to protect the inner space of the building from the penetration of moisture and all unwanted impacts of the external environment. Laying the roofing roof, as well as using it for waterproofing basements. It is also used to repair damaged coatings and as a subtenitory layer for mounting materials with a tree base.

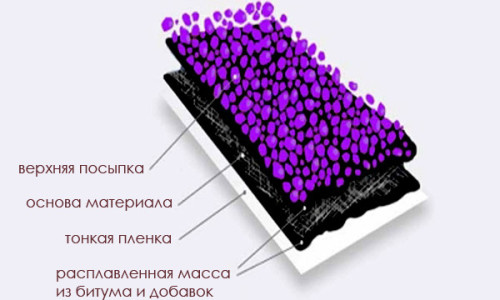

Ruberoid is a special high-strength cardboard, which is saturated with an oil bituminous mixture and refractory bitumen. The outer layer is represented by a special powder made of mineral crumbs. It protects the bituminous part of the destructive effects of ultraviolet, and also creates a non-slip rough surface with good adhesion.

It is very important to choose a rubberoid with high-quality impregnation, because otherwise the durability is significantly reduced and the quality of the product is worse. Therefore, to acquire the material is recommended for proven manufacturers with experience in the market for more than 5-10 years and the presence of all quality certificates.

To cover the roof of the rubberoid, you can use several species of this material:

- Rubext - material from dense roofing cardboard is based on astringent bitumen. From an ordinary rubberoid, it is highly resistant to cracking and plasticity.

- Gymelockeroid - the material is almost identical to the Rublest in the only exception that there is not a building cardboard at the base, but more wear-resistant and durable fiberglass.

- EuroRuberoid - this variety is also characterized by the basis and is the most expensive of all. Bituminous impregnation and mineral powder are applied to a polyester base. It is quite flexible, moisture-resistant and durable. Such rubberoid roof with good care will last 15-20 years.

Unfortunately, even the most expensive rubberoid may be poor quality, and not to waste money, you need to know how to check the material before purchasing. Roll off the rolls and spend a visual inspection - the surface must be homogeneous and smooth without folds, cracks, impregnation in impregnation and even more through damage. If you find light spots, it speaks of uneven impregnation of the base with a bitumen mixture.

Marking Ruberoid

To cover the roof of the bitumen and get a durable and reliable protection against bad weather, it is necessary to correctly choose the type of product. This will help special labeling, which helps to distinguish materials with different base density and mineral powder type.

Ruberoid marking:

- RKK 350 - Ruberoid with cardboard base. The digit means the density of the cardboard 350 g / m². Such material is used to form a finishing layer of roofing cake with a protective coating of coarse talcomagnesite. This is one of the most inexpensive types of roofing regularity, but its service life will be quite short - up to 7-10 years.

- RKK 400 - Material based on increased density. It is more suitable for coating the roofs, because it copes better with atmospheric influences. The moisture protection characteristics are high enough due to the presence of an additional layer of asbogal.

The letter "M", "K" and "P" in marking means the size of the granules of mineral powder: small, large and scaly, respectively. Minute is usually used to create a lower and medium moisture protection layer, and large - for external.

Roof Ruberoid Installation Technology

There are simple rules for laying a runneroid that will help you quickly and efficiently make roofing work. First, it is better to choose a dry, warm and glad day for mounting. Secondly, you need to prepare the basis for laying a runnerdoor. If this is concrete, it needs to be cleaned and aligned, perhaps, pour an aligning cement tie. If we are talking about the coverage of the wooden roof over the rubberoid, it means that you need to create a solid crate of moisture-resistant plywood or chipboard. The concrete base is to be brought to a concrete contact in several layers, wooden - wood-primer. Thirdly, before assembling, pay special attention to all plates for docking the roof with pipes (drain, fireplace, ventilation), mansard windows, parapet. There, when installing Ruberoid, it is recommended to use waterproofing mastic.

Useful advice: Under the layers of the rubberoid, moisture will be accumulated in time, which ultimately leads to its bundle, bloating and destruction of the protective layer. To prevent such a development of events, set several aerators on the roof to evaporate moisture.

You need to store the runneroid only after the completion of works on the organization of the attic space. In other words, the ventilation system must already be installed, paro insulation of roofing pie is laid, and the drainage is properly performed. Water disposal from the roof is very important, because otherwise the fluid will be stamped, quickly destroying the runneroid and leaking inside. In winter, the water will freeze and turn into icicles, and the parts leaked into the roofing cake will increase in volumes and destroys the roof from the inside.

For reliable protection of the roofing system, the installation of the runner should be made in several layers. Their amount will depend on the roof configuration. Thus, for a flat operated roof, it is recommended to fix at least 5 layers of the rubberoid, for non-exploitable 3-4 layers will be enough. Scope roofs require a little different approach. On the inclined surface, it is much more difficult to work and more dangerous. The thickness of the roofing carpet in this case will depend on the angle of slope. If the slope is up to 15 °, no less than 3 layers of the material will be required, if the slope is greater than 15 °, you can limit the minimum two layers.

Several ways are used for mounting the runneroid to the surface:

- Mechanical fixation by nails, dowels, anchor bolts (applicable more applicable for wooden bases).

- Printing to bitumen mastic (mastica provides not only reliable fixation, but also an additional waterproofing layer).

- Pointing by gas burner.

Flat roofing

As it is already known, to obtain a high-quality and durable coating of a flat roofing rubberoid preferably lay in 5 layers. At the same time, for the bottom layers, it is better to choose a material with fine-grained powder so that they are as close as possible to each other.

Since the runneroid is sold in rolls, to cover the surface, it will be necessary to eliminate several cuts nearby. They must go on 10-15 cm, while the joints need to be sized with bitumen mastics. The last outer layer must be made from the rubberoid with a coarser-grained mineral sprinkler. Most manufacturers leave small strips without powders on the sides of the roll for a stronger connection of cuts. If, in your case, there are no such "clean" strips, it means that for a dense connection, the canvas need a sufficiently thick layer of adhesive mastic. However, experts recommend nevertheless to carefully consider the rewriting in the connection places, and then glue cuts. This takes out some time, but the protective layer will be more reliable.

Horizontal roofing technology Ruberoid:

- Clean the surface from any garbage and contamination.

- Check the horizontal surface of the surface and, if necessary, align it, steesv bugs or covers the depressions with cement mortar. In the case of serious drops in height, it is recommended to pour an aligning screed. Add plasticizers to the cement solution to increase the screed resistance to moisture.

- Thoroughly dry the surface before laying.

- Cover the surface with several layers of primer composition, waiting for the complete drying of each of them before applying the subsequent. For concrete, use the primer concrete contact or penetrating waterproofing, for wood - composition for wood. You can also make high-quality primer yourself, mixing 4 liters of bitumen, 6 liters of kerosene and 1.5 chalk powder.

- If you do not have experience in such work and you do not have a special technique (gas burner for the flooring roof), the easiest way to paste the rubberoid on mastic. Alternatively, you can use the roof of the roof of the roof of the rubberoid. In this case, it is enough to remove the protective film from the bottom side of the cut and glue it to the surface, carefully placing. It is necessary to work quite quickly, otherwise the adhesive layer can dry. After that, the surface is recommended to roll a rink.

But the self-adhesive runner is quite expensive, so many stop their choice on the attachment of bituminous mastic. To do this, it is necessary to make mastic on the surface of the roof, processing the area in the width of the rod rubles, and carefully roll out the roll, placing the material from the middle to the edges. If you at least once in life glued wallpaper, then the technology will seem like you very familiar. It is necessary to drive out from under the ruberoid all air bubbles, but if it did not work out, the bubble must be pierced with a selection and tightly press the material to the surface. - Stick the first layer and leave it to dry by 12 hours. Only after that can be accepted for the second layer.

Scope roofing

In the case of scope roof, it will take to mount a solid crate of moisture-resistant plywood, edged or umbered board, chipboard or OSB, since it is possible to create a smooth and sufficiently rigid surface.

To cover the double roof, the rubberoid can be used in the following ways of installation:

- Locate the web horizontally, starting laying from the cornice and placing ceases to be 10-15 cm.

- Locate the linen along the lines of the slope, starting laying from the front and making the side backstage of 10 cm.

- Use a combined method, laying the bottom layer across, and the upper one, or vice versa. In this case, you can achieve increased moisture resistance and density of the coating.

Each of these methods provides high-quality protection from the wetting of roofing pie. If you do horizontal laying, you will need to help one person so that it supports the opposite edge of the canvas. If you work alone, it will be necessary to temporarily fix the cut at the other end, and this will break its integrity.

On the pitched roofs, the runneroid is always mounted in a mechanical way, since it is quite difficult to use a mastic or canvas, and for this will require special equipment for high-altitude work. The lower layers are better to navigate galvanized nails with wide hats, and for mounting the upper use wooden rails or solid metal strips (galvanized metal or aluminum).

Useful Tip: Before mounting, measure the roof and cut the ruler for cuts of the desired length.

The root protection technology is believed to be one of the most economical and simple. The most important thing is to choose high-quality material and observe the laying technology, and then the reference coating of 4-5 layers will serve as much as the roof of galvanized steel.

Finally, we suggest to see the informative video about the roof cover Ruberoid do it yourself: