Roof coating with her hands Construction

During the construction of the roof, different materials are used as a roof: it is slate, and a tile, and many others. But the roof of the roof remains the most popular. If there is a material, you can make roofing work yourself.

Content

Types of materials

Iron is the widespread concept of roofing materials. Therefore, starting to roofing work, you need to figure out what kind of material it will be suitable:

- Coating the roof steel - in this case, the most ordinary iron is used, this material is durable and has good resistance to physical exposure. The minus became that it is subject to corrosion, it is very shortening the service life.

- The roof coating with galvanized iron - this material serves longer than ordinary iron, as the sheet is covered with zinc, which is resistant to corrosion. An even more reliable and attractive galvanized iron makes a polymer coating. This applies to the professional flooring and its varieties - metal tile.

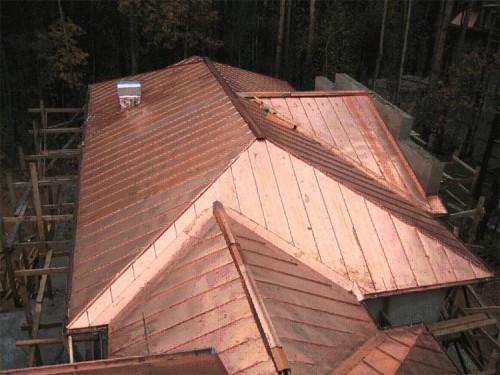

- The roof coating with a non-ferrous metal - last time it became popular to choose such materials such as copper, aluminum, zinc-titanium for the roof. They make the roof reliable and expressive in the architectural plan.

Pros and cons of iron roof

Positive sides of the roof of iron:

- when preference is given to the selection of materials, the roof coating with iron, many loses the low price. And it really is, because steel sheets are much cheaper than the same metal tile, but serve for a long time;

- iron can cover the roof of even the most complex design;

- easy weights makes builders, like simple work technology, and the delivery of light sheets costs cheaper;

- the strength of the material allows without fear to walk along it during roofing;

- the life of such a roof is quite large: from 18 years to a quarter century;

- metal roofs are easy to paint and repair;

- this material is considered environmentally friendly.

Among the minuses of the coating of the roof of iron can be allocated:

- not high fire resistance;

- operation costs: Such a roof needs frequent painting.

Preparatory stage

The roof coating with its own hands begins with sheet steel preparation. When transporting, you need to be extremely neat so that there are no scratches and chips.

- With a metal sheet, remove the lubricant layer.

- Top are applied with olif, which is enriched with dyes.

- After the olive is dry, you need to identify unfinished places and paint.

- On the edge of the sheet began to betned otset - the technological fastening element, which is also called the lock.

Falset is two types: standing and lying. Combined sheets can be both longitudinally and transversely. And only in metal tile sheets are stacked by Vansel.

Production of fold

To make a fold independently, you will need tools:

- calipers;

- grebeliegyb;

- tree mystery;

- scissors for metal;

- workbench with a steel corner, a metal hammer with a flat sideway;

- ruler.

With this set of tools you can make a lying folding.

- Put iron sheet to the edge of the workbench.

- Place the edge line, holding the sheet so that the line goes smoothly and not shifted.

- With the help of the Cyanka, the angles of the edge exactly along the line should be able to get a light beacon. It will make further work to produce more accurately.

- After the bend is made along the entire length of the edge, you need to flip the iron sheet and break the edge to the end.

- It is also necessary to treat another sheet, then it will be possible to combine them with each other.

- Connection locations must be fixed with a hammer.

- The longitudinal edge gives the required scar.

Standing Falk is made on the same technology on the roof. To make a castle for ordinary sheets you need to use the Grebelbab.

Roof coating technology

It is possible to prepare iron sheets to roofing work in the workshop, but they need to be mounted on the roof itself. Before starting work at the height, you need to make preferential elements directly on the site from the sheets. So easier then will be mounted.

What makes the right roof covering iron you need to follow the instructions:

- With the help of finished lying folds, iron sheets are connected to each other. The prefabricated element should at least consist of two sheets on the short side, and as a maximum - to the entire height of the roof rod.

- Secure flex between sheets, observing one direction.

- Check whether the sheets are located relative to the vertical.

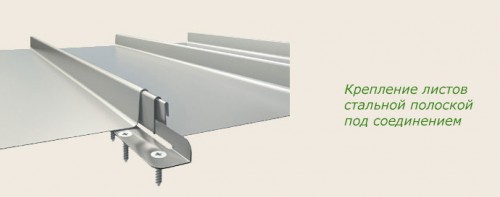

- With the steel strip and hammer to strengthen the compounds.

- The inflection through the horse must be done so that the edge on one slope is driven by 6 cm, and on the second to 3 cm.

- Fix the iron you need, first covering the flexion from the skate, and then by mounting the entire strip.

- The sheets are fixed by the curvatures that are attached to the roof shabby, to the bars.

- If the sheets are profile, it is necessary to mount them to the roof you need special nails with rubber seals.

The roof of the polymer coating materials will not need to cover the top over all years of operation. But the usual steel will need to be primed and painted. It must be done immediately after the completion of roofing works. Painting steel sheets need twice. What the roof cover looks like iron can be viewed in the photo.

Roof mounting features near chimney

Today, many private houses still have chimneys on the roof, and work on the roof in these places are considered rather complex.

- Before starting work, you need to carefully measure all the roof parameters, so that after the roof is in place, the rainwater did not register inward near the chimney.

- Harding the size of steel sheets, prepare them for installation in the workshop.

- Make a collar that in shape will match the pipe.

- A collar with sheets and a pipe with standing or inclined folds is connected. For roofs from the profile, additional elements can be bought from any construction store.

You can look at the roof cover in more detail on the video.