Wetting plates of overlappings: characteristics and features Construction

Who at least once happened to deal with the construction site - whether it is the construction of a country house or a solid apartment renovation - he knows what huge slabs of overlapping and how large their importance for construction or repair. The main characteristics of the product, the features of its design and labeling are always taken into account during the work: with the help of these knowledge, it is possible to determine which limit of the useful and decorative load is able to withstand the void hollow slab.

Content

- Varieties and benefits of the product

- Wetting plates of overlap: dimensions and weight

- Materials and features of the design of hollow slabs overlap

- Types of loads on the hollow reinforced concrete construction

- Brands of hollow slabs overlapping

- How to calculate the maximum permissible load on the wetting plate of overlapping

- How to determine the optimal load for the stove?

- Features of repair in old rooms

- Method for the manufacture of empty slabs overlap. Video

Varieties and benefits of the product

Plates of the blocking of factory production are characterized by high quality characteristics, as they create them in strict compliance with the temperature and hardening time. The construction uses two modifications of overlapping slabs: full and void.

A full-scale plate variety has a lot of weight and, accordingly, high cost. In this regard, full-scale slabs of the overlap most often are in demand in the construction of important buildings. Wedding floors of floors have been widely used in the construction of residential buildings. They are relatively easier and cheaper than full-scale plates, but they are not inferior to them in strength and reliability. Neither the amount of emptiness nor their location reduces the carrier properties of the plate. In addition, it is thanks to the voids that the sound and thermal insulation features of the structure increase.

The positive characteristics of void floors made them most popular among reinforced concrete products: they are used in the construction of multi-storey facilities, in the construction of private and monolithic buildings. Often, empty overlap plates become a carrier frame for buildings.

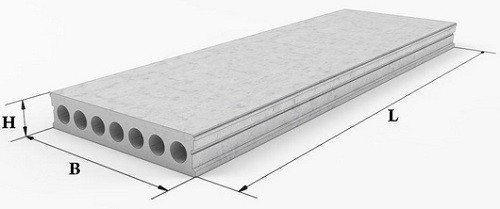

Wetting plates of overlap: dimensions and weight

The final cost depends on the type and size of the product. The sizes of the plates vary from 1.18 to 9.7 m in length and from 0.99 to 3.5 m wide. The most demanded products, the length of which is 6 m, and the width is from 1.2 to 1.5 m. The height of the hollow slab of the overlap is a constant value: it is equal to 22 cm.

Given the large weight of the wet floors of the overlap, the mounting crane is used for their installation, the power of which is no more than 4-5 tons.

Materials and features of the design of hollow slabs overlap

The raw material for the manufacture of hollow plates is concrete, mixed on the cement M300 and M400. The qualitative characteristics of the material are taken behind the numbers, which will subsequently be inherent in the finished product. So, the cement with marking M400 withstands a single-time (not constant) load of 400 kg per 1 cm 3/ sec. Cement M300 brand is a derivative of the mixture from M400. And although this material is withstanding a more modest load, it is distinguished by sufficient plasticity so as not to be broken during deflection.

In addition to concrete, in the production of hollow -genic plates is used intense or ordinary fittings: the high carrier capacity of concrete is achieved due to the reinforcement. Honeycomb plates reinforced using stainless steel class A3 and A4, which is characterized by increased corrosion resistance and temperature drops from - 40 ° C to + 50 ° C.

Modern production of reinforced concrete structures practices stretch reinforcement. This happens as follows: the reinforcement is stretched in advance in the form, after which the reinforcement grid is placed there. It distributes the tension of the stretched components to the entire area of \u200b\u200bthe hollow plate. Then the shape is filled with concrete. When it becomes solid and strong enough, the stretch elements of reinforcement cut.

This method of reinforcement allows the wetting plates of the overlap not to sag and not be fed, withsting a solid load. In the ends of the hollow plate, which it rests on the bearing walls, is mounted double reinforcement, thanks to which the ends are not only not deformed under pressure from their weight, but also withstand the load from the upper bearing walls.

Types of loads on the hollow reinforced concrete construction

In the structure of any overlap, three parts are distinguished:

- top with a residential floor located above. It includes flooring, screed and insulating elements;

- lower part with a residential area located below. It consists of the ceiling finishes and suspended elements.

- the construction part, which combines the upper and lower parts and holding them in the air.

The wetting stove of the overlap fulfills the function of the third, construction part. Finishing elements that are used in the design of the floor and the ceiling have a constant static load on it. Under the decoration of the floor and the ceiling, they mean all the elements that hang to the overlap or put on it: chandeliers, suspended ceilings, boxing pears, columns, baths, partitions.

In addition, there is also a dynamic load on the wetting plates of the overlap - it creates objects moving over the surface of the overlap. Moreover, not only the effect of the mass of a moving person, but also a mass of his pets, which are very exotic (lynx, tigers, etc.)

Now consider the distributed and point type of load. For example, a huge boxing pear hanging to the ceiling is a point load. But the suspended ceiling, which in its frame at an equal interval of the distance contacts the suspensions with overlapping, can be called a distributed load.

Point and distributed load can act comprehensively, in this case the load calculation is complicated. Thus, installing the bath, the capacity of which is 500 liters, take into account both types of load. First of all, this distributed load that the filled bath has a support area between the legs, as well as the point load that each leg of the bath is separate.

Brands of hollow slabs overlapping

All reinforced concrete products that are produced at the factory are subject to labeling, which is essentially encoded information.

The slabs of the overlap are denoted by two capital letters of the PC. This abbreviation follows the number indicating the approximate length of the product in decimeters. The following numbers are an approximate width of the plate in decimeters. The last indicator reports what weight in kilograms is withstanding 1 dm 2.products, taking into account its own mass.

For example, the data on the plane of the overlapping PC 12 - 10 - 8 reports that the length of this product is 1, 18 m (about 12 dm), and the width is 0.99 m (about 10 dm). The highest load that the product can withstand is 8 kg per 1 dm2 (800 kg / m 2).

Note that the load of 800 kg / m 2 Almost for almost all hollow slabs overlap. The exceptions are products withstanding up to 1000 and 1250 kg / m 2: Their marking ends, respectively, figures 10 and 12.5.

How to calculate the maximum permissible load on the wetting plate of overlapping

Consider the features of the floor slab mounting. Its installation depends on the support scheme, as well as from the quality and weight of the slab itself. It is very important to make the right calculation of the hollow slab overlap so that the product last time. How never is the most accurate mathematical calculations, if the building is built on the territory with increased seismic activity.

Overlapping slabs Empty (GOST 9561-91) produce different sizes and different thickness, which ultimately determines their ability to hold one or another load.

In order to determine the greatest load that the overlap will withstand, draw a detailed scheme of construction (houses or apartments) and calculate the total weight of everything that will "put pressure" to overlap. First of all, take into account:

- gypsum concrete partitions;

- warming of floors and clamzite floors;

- cement screeds;

- mass of floor plates or parquet coating.

The total weight of the load shall be divided into all the plates that will keep this load.

Bearing walls and supports for the roof are placed only by the ends, since the inner parts are reinforced so that the main pressure accounted for ends. The fact is that the center of the hollow plate does not withstand the load that massive structures give, even if the slab is supported by support columns or capital walls.

How to determine the optimal load for the stove?

First of all, you need to know the weight of the slab itself. The algorithm of mathematical calculations to determine the necessary data will consider on the example of the PC-60-15-8 plate (GOST 9561-91), the weight of which is 2850 kg.

Calculate what weight is 1 m 2 Square in 9 m 2: 2850 Delim to 9, as a result we get 316 kg / m 2. Now, from the maximum possible load, we will take our own product weight: 800 kg / m 2 - 316 kg / m 2 \u003d 484 kg / m 2.

I will estimate how many a total of items can weigh the objects that subsequently put on the floor: screed, insulation, outdoor coating. Suppose this weight this approximately equals 150 kg / m 2. Now, from our own weight, we take a common mass of objects that create a load on it: 484 kg / m 2 - 150 kg / m 2 \u003d 334 kg / m 2.

In addition, from the remaining 334 kg / m 2 we need to take away 150 kg / m 2 - This is a "alive" weight of people, as well as furniture, without which it is possible to do. So, 334 kg / m 2 - 150 kg / m 2 \u003d 184 kg / m 2. The location of the doors and partitions are planning, calculating 184 kg per 1 m 2.

Features of repair in old rooms

When planning a major repairs in the apartment of the old house, after dismantling the old floor insulation and the coating, it is necessary to determine their approximate weight. If possible, new plates, parquet or screeds need to be picked up so that their mass is about the same as the old top coating plate.

With extreme caution you need to place in old apartments. Modern plumbing of increased volumes - jacuzzi, huge baths. Ideally, a literate specialist should be engaged in detailed calculations to determine the maximum permissible loads.

Always take into account the workload features: short-term and constant static loads - not the same thing. Short-term pressure is tested how strong the stove is, while static over time leads to its defunitions and deformation.

Successful and reliable operation of empty slabs of overlapping is possible only with the steady observance of all rules and thorough preliminary calculations before assessing them.