Plaster Plasterboard: Step-by-step instructions Walls

Plasterboard is a universal building material, which today is applied more and more. With it, you can not only sow walls, but also create unique design solutions. Despite all the positive properties of plaster material, it is also necessary to think about the high-quality plaster of its surface.

Some experts claim to apply plaster on plasterboard - not the best solution. This is due to the fact that gradually the gypsum material begins to deform, and this is no matter what quality is this construction resource, and with what scale we are dealing with. Accordingly, during deformations, plaster will begin to actively crack. After some time, the surface of the plasterboard will be just terrible.

Fortunately, several interesting decisions have recently appeared, with which you can easily achieve the desired result. It also comes to the fact that no deformations and warranties of plaster will not be guaranteed.

Content

Features of choosing plaster

To date, there are a large number of plaster options in the construction market. Of course, all these finishing materials are distinguished by the properties. Accordingly, some plaster options can be applied in the construction of industrial workshops, and some are exclusively in residential buildings.

Very often, it is possible to find plaster, which is intended solely to cover the gypsum material. Most likely, it will cost somewhat more expensive analogues, however, ultimately the result will be quite decent.

In any case, if the plaster is purchased, you should consult from specialists who will offer the most suitable option for certain conditions.

Conducting gypsum carcarter

It rarely occurs in such a way that after arranging the wall, curvatures and other surface flaws are manifested by leafs of plasterboard. In such conditions, it is necessary to carry out a putty material. In this way, we perfectly prepare the surface to the main process of plaster.

If there are serious bends of drywall, it is likely to be re-installed.

Immediately it should be noted that moisture-resistant plasterboard should be used for such work. Otherwise, the material will begin to deteriorate significantly, making the appearance of the room is not the most attractive.

At the very beginning, you need to carry out the primer of plasterboard. This process will significantly improve the quality of the most construction resource, and also to do everything possible so that the putty and the plaster for a long time spent qualitatively on the surface.

Below are the main properties of most primer compositions for drywall:

- resistance to large amounts of chemical factors;

- improved adhesion;

- moisture resistance;

- heat resistance;

- binding dust.

Moreover, the primer prevents the fungus, bacteria on the surface of the drywall, and mold. This is especially important in cases where there is relatively high humidity in the room.

If you combine all the factors presented, we can safely say that the primer makes drywall more durable.

Often the primer comes in small canes. Application occurs using a roller, although the usual brush is quite suitable.

It is not too diligently to apply material, and not a very large layer. At the same time, all seams need to be carefully filled with primer, since they are the main source of many problems.

When buying primer, you need to pay special attention to the manufacturer. The market is simply filled with poor-quality products, which can adversely affect the condition of the plaster material. Also primer has a shelf life. After some time, the properties of the material can change significantly.

As for the choice of putty, then there is a cement, polymer and gypsum material. All three options can be used, however there are some limitations.

For example, cement putty is often used in rooms where there are temperature differences. This is a bathroom, as well as a kitchen. Gypsum putty is most often used in ordinary rooms, where people spend most of their time. Polymer putty, as you can already understand from the name, is universal. She recently appeared on the market, however, he had already managed to gain a huge share in the construction market.

Immediately before putty, you need to carefully check the wall surface so that nothing bothered the main process. It is about the fact that the walls should not be stitching, as well as other fasteners. If you can tighten the fastening in such a way that they are on the same level with plasterboard. However, it is necessary to do it carefully, so that it is not accidentally pressing the self-tapping screws into the material.

It also happens very often that at the edges of the sheets of plaster material there is a detachment of the paper component. If you cover this part of the plasterboard with plaster, then after a short period of time, the finish can simply fall off. Accordingly, on the edges, the material is best trimmed. It is necessary to do it so that with the help of a putty it would be possible to hide all the flaws. Cut the part of the cardboard coating with the help of a stationery knife.

The main process of spacure

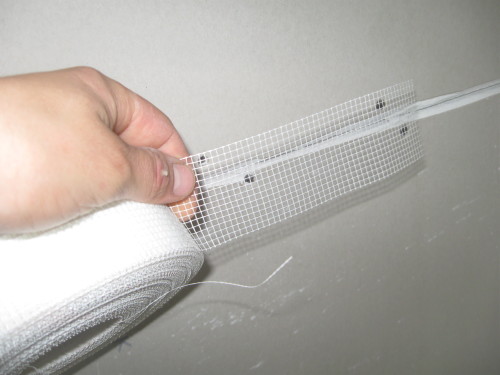

Immediately before putting on all the corners and joints, the grid is pasted, which is often referred to as CERPYAN. It will allow you to sharpen all the problem areas. Definitely, it is not necessary to do without it, because in the corners and joints, the putty keeps far away, as in the other places.

It is necessary to breed putty in minimal volumes that should be enough for specific work. It is worthwhile that this material will dry very quickly, but to store it in a divorced state - it does not make any sense.

For seams, we will need medium and large spatulas. The putty is applied with a thin layer, but it should be done so that after the putty the glued grid it was not visible. First, the spatula needs to spend along the wall, and then it is across to fill all the hard-to-reach places with a putty.

For putty in the field of self-sufficiency, it is necessary to use the cruciform appliance technique. However, the most difficult is putting the corners. In this case, you will have to spend a lot of time to get the desired result. To fill all emptiness, it is necessary to apply the material again along and across.

The process of plastering surface

Plastering of the drywall surface is carried out in those strict cases when small irregularities are present. Accordingly, in such cases, the material is applied a very thin layer.

To begin with, it will be necessary to clear the surface of the plasterboard. It is impossible to assume that at least a little dust in the plaster material. After that, the main process begins. Plaster is applied, as in the past case - along and across, with a thin layer. It is necessary to do everything possible in order to ultimately the plaster dropped immediately after smoothing. This suggests that the thickness of the layer is ideal for the presented requirements.

Creation of decorative plaster

Of course, the usual smooth surface of the plaster is good, but this is not the result that the owners of apartments want to get owners. Of course, we are talking about decorative plaster, which is capable of improving the appearance of the room several times, as well as all housing.

It is worth saying that there is nothing complicated in the process of creating a directive plaster. Just just know a special this process to get a really good result.

Most often, it is necessary to apply a sufficiently large layer of putty to the surface of the decor. It is also possible to apply this layer on the already aligned surface. However, that layer that will perform the function of the decor must have a gypsum component.

The field of applying putty can be activated with a malarious roller. If they spend on a spacious surface, it will immediately be possible to notice a unique texture. Such a drawing can be applied by waves or diagonally. The main thing is that it looked quite solid and harmoniously. Given that the texture turns out to be large, this option is best suited for large housing.

With the help of a conventional spatula, you can smooth out too large texture. Even in this case, we will get an excellent designer solution that is ideal for any room. The resulting texture can be observed on the external walls of a large number of buildings. However, in our case, the texture will be in a measure smooth and pleasant eye.

Special mixtures are also available on sale, which are great for creating a leaf-based texture. Bad news is that the flow of these materials is very large, so here we are dealing with great financial costs.

Decorative plaster and textured rollers

Surely many have seen rollers who have a certain texture. They are used precisely to create the original texture based on plaster. Interestingly, with the help of such rollers, you can create a wide variety of design solutions, choosing between drawings and depth texture.

Unfortunately, when buying such tools it is quite difficult to imagine how it will look like a wall after the work performed. Sometimes rollers are divided by image textures, which is very useful.

Again, it is recommended to use textured rollers, the texture of which is not too deep. In small rooms it will be best to look like barely notable images.

After applying plaster, you need to spend such a roller from the very top - down. The same procedure should be carried out throughout the wall, creating a certain interval between the decorative elements of the surface. As in the past case, the resulting images can be slightly smoothed with a spatula.

The process itself should take place very quickly, as even decorative plaster dries quickly.

Such decorative reception can be used in separate places. All this should look harmoniously. It is likely that in front of such works it is best to analyze various photos on which such a finish is present.

Immediately after drying, the plaster starts painting. Small recesses can be left in the original color of the finishing material.