Methods of fastening pipe Plumbing

Reliable fastening of engineering communications pipes has a direct impact on their service life. For cases where water supply or sewage is not laid in the stroke, use various ways to fasten the pipe.

Content

How and what fasten pipes

The outer fastening of pipes, depending on their material, is most often carried out with the help of plastic clips or metal clamps with rubber gasket.

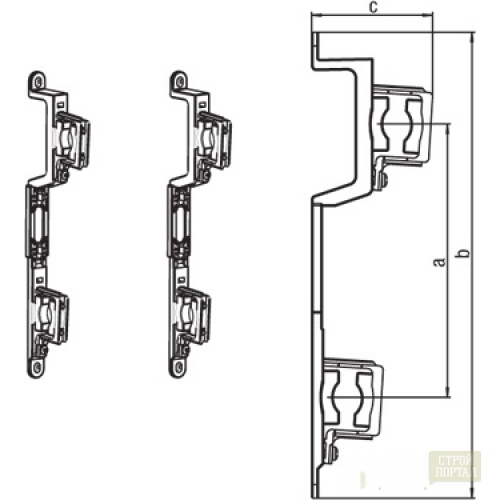

Clamps for fastening pipes

Made clamps made of zinc coated steel. They are harvested with screws from two semi-colts, one of which is attached the stud. The semiring is connected by screws. To reduce noise from the vibration of the pipe, the kit includes a rubber gasket. The diameters of the clamp are different - from 14 to 222 mm. The fastening of pipes is performed in such a sequence of actions.

- On the axial line of the pipe at its fastening on the walls of the wall put marks of fixation points.

- Using the perforator in a brick or concrete wall in marked points, the holes under the plastic dowels are drilled. The distance between the attachment points is chosen in this way (usually 0.5 m) so that the pipe is not deformed. Near the pipe bends, additional clamps are set at a distance of at least 150 mm from the angle.

- Insert dowels into the wall and screw the clamps until it stops. The steel clamp for fastening pipes must be focused perpendicular to the pipe itself.

- Lower the lower screw, connecting the semiring of the clamp, and move the front half rings down.

- Place the pipe into the clamps and fix it, tightening the semiring screws. Tighten all the screws until you stop.

Important: For fastening the hot water pipeline or heating, clamps that do not prevent the expansion of the material are chosen.

Clip for fastening pipes

Plastic clips are most often the fastening of polypropylene pipes for water supply in rooms. Clips are double (for fastening the water pipeline of cold and hot water, laid in one direction) and single. Use such fasteners for pipes to fix light communications with a diameter of no more than 50 mm. This is performed as follows.

- There are places for drilling holes for clips.

- The perforator is drilled by holes.

- Paste plastic dowels clips into the holes and pressed against the wall. If design is provided - screwed screws into the hole of the dowel (for better fixation).

- The pipe is inserted into the clips, which first expand, and then compress and tightly clasp the element.

IMPORTANT: Fastening the pipe to the wall, the floor or ceiling must be performed taking into account the temperature expansion of the material. For hot water pipes or heating, additional pipe fastening nodes provide. It is necessary to minimize the bends of the pipe under direct and acute angles to avoid blockages. Pipes to the ceiling are fixed with the help of anchor bolts.

Metal Pipe Bracket

It is possible to securely fix the pipe from metal plastic using special brackets. Unlike clips, at the top of the brackets there are special clasps that do not allow the pipe to shift. This is important when installing vertical communications.

Fastening sewer pipes

The fastening of plastic sewage pipes by an outer method is carried out using metal clamps. A plastic bracket can also be used for fastening pipes with a special clasp. They need to be located near the connections of sewage parts to increase rigidity. The following rules should also be observed.

- When laying pipes into a screed or stroker, you need to put them in a corrugated sheath or polyurethane cuff: this will allow plastic to extend freely. In the extreme case, you can use corrugated cardboard.

- Fastening for risers should be placed coaxially, the pipe should defend the wall at least 5 mm.

- Placing points to install the sunbeds, for normal runoff there must be a minimum bias - 20 mm per 1 m.

- The distance between the wall and the pipe is lying bed must be minimal: it is important for the rigidity of the entire system.

- For a dialing sewer system from pipes with a diameter of 100 mm, the fasteners are installed at a distance of no more than 800 mm from each other, for pipes with a diameter of 50 mm. This distance is 400 mm.

- For the installation of a large diameter of the pipes of the sewer system, only metal clamps are used. The interface of the elements will be the best if you use all the fastens of one manufacturer and one brand.

- The use of wooden aggregates instead of plastic dowels is not allowed.

Important: For pipes, you should choose the fasteners of only the corresponding diameter. A small clearance is allowed to compensate for temperature expansion, which is especially important in the unheated room.

Fastening steel pipes

In some cases, it is necessary to solve the problem of fastening pipelines from metal. Such material is still used when installing heating and water pipes: pipes made of copper and stainless steel serve longer than plastic.

Molding for metal pipes is also made of metal. It may be:

- bracket for fastening pipes;

- clamp with rubber gasket and without it;

- bracket.

During installation work, the following nuances should be taken into account.

- With horizontal laying of pipes, fewer fasteners are required than with a vertical: in this case, the weight of the metal does not have bending effect. The distance between the clamps for the vertically laid water supply increases by 10%.

- For thin pipes, more fasteners are needed than for thick.

- In the lower part of the vertically installed pipe, turning into a horizontal plane, an additional rigid metal clamp must be installed for fastening pipes. The deforming load should not be transmitted to the sun bed.

In the event that it is necessary to fix or connect the pipes of the rectangular (square section), use fasteners repeating its contour. This is used when assembling greenhouses with a metal frame and racks. The fastening for the profile pipe can be t-shaped, cruciform and direct.

How to mount warm floors

The collector cabinets establishes a set of special brackets for distribution comb. Pipes in them are clamped with plastic or metal clamps. On the floor surface, the pipeline is fixed with brackets to the insulation, to the reinforcement grid or to a special tape.

The information set out in the article will help independently perform installation, the quality of which will not give way to professional when complying with the basic rules.