Welding and welding for beginner. Tips of professionals Useful advice,Construction

Without welding work, almost no industry, and the welder services are relevant at any time. Having received the profession of electric welder, you can be sure that the employment will not be particular problems. The profile of possession of welding equipment is determined by the professionalism of the wizard. But first should you deal with the Aza welding and consider the main techniques.

What any welder should know

Any welder should thoroughly know how to manage with welding equipment, to know the principles of its functioning, skillfully and quickly prepare it to work and eliminate possible breakdowns. To do this, you need to be familiar with the device of the mechanism and understand the mechanics of impact on metals.

Also, the welder should know the properties of the metals used in the industry and, guided by its knowledge, choose the optimal welding option. The complexity of the activities of the electrode welders lies in the fact that even a small change in the mode of operation of the device may be adversely affected by the quality and durability of the entire structure.

Initial training of electric welding can be divided into several stages:

- study of the principles of equipment;

- safety;

- aza electric welding;

- study of welding seams.

Each stage is associated with practical lessons along the course of learning. Ideally, next to the student, an experienced welder must constantly be. If you intend to learn the welding yourself, it is worth ensuring maximum safety and clearly follow the instructions.

In order to get a job as an official welder, it is necessary to obtain a corresponding diploma on the end of the educational institution. If you want to just understand the principles and technology of work and enjoy welding for personal needs, you can explore the material yourself.

Aza welding

Before you begin learning, you need to buy or rent a welding machine. Also does not hinder a large number of electrodes, because during their studies most of them will be spoiled - they will not get anywhere. Before you reach a permanent less than a decent result, it will take more than a dozen electrodes. To carry out welding work with your own hands at home, it is better to buy electrodes 3 mm in diameter. This is the best option for beginners, because if you buy more subtle, it will simply blown, because they are intended for more "jewelry" works, and thick electrodes provoke an overload of the power grid.

Manual meadow welding will require a lot of patience from the student and even more perfection. Only with constant practice can be achieved good results. If you have familiar welders, it is better that training takes place under their control, because it should be done wrong much more difficult than to immediately do everything right.

Progress:

- For the practice of metal cooking, a piece of unnecessary metal is suitable. Prepare a workplace, set a bucket of cold water near it. Do not work on a wooden workbench - remember the rules of fire safety, since even the smallest particles of the electrodes can cause fire.

- Firmly fix "Ground" to the details. "Earth" must be well isolated.

- Stop the required current power in accordance with the electrode diameter.

- Light an arc, putting an electrode at an angle of 60 degrees to a metal surface and spending them slowly. When sparks appear, touch the electrode to the metal, lifting it so that the space does not exceed 5 mm. With properly performed actions should be lit arc. Maintain a distance of 5 mm is necessary for the entire workflow. It comes with practice, it is necessary only to "fill the hand." Remember that the electrode is unborn over time, then it must be moved immediately. Shipping the electrode is easy to eliminate if gently swing it to the side. If it fails to burn an arc of up to 3 mm long, increase current strength. Ideally, you must try to keep the arc to 5 mm between the electrode and the detail.

- When you got a steady arc, work out in the roller surfacing. Light and slowly move the electrode in the horizontal direction, producing oscillatory movements and as if "edrebing" painted metal to the arc center. As a result, you must have a cute wavy seam.

Technology welding

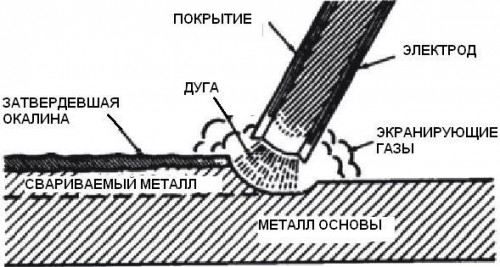

When a positive pole of anode is connected to the product, straight-polar manual welding is carried out. If you connect a negative pole, we will get inverselyolar welding. The melting of the metal "body" of the electrode, its coating and the product itself occurs under the influence of the arc. Melted, the electrode metal turns into drops that are covered with slag. These drops go to the welding tank, where mixing with the main metal and the removal of the slag.

The dimensions of the welding reservoir depend on the position of the apparatus in space and mode of operation. It also affects the design, shape and size of the processed edges, the speed of the arc stroke, etc. Typically, dimensions vary under certain limits: the width is from 8 to 15 mm, the depth does not exceed 6 mm, in length from 10 to 30 mm.

The length of the arc is the space between the two active stains, and one is on the surface of the welding tank, and the other is located on the hot surface of the electrode. When the electrode melts over the welding tank or next to the arc, gas is released, which pushes the air from the welding space and prevents it from entering the liquid metal.

The slag, which covers the entire surface of the welding tank and drops of a hot electrode, does not allow the metal to interact with oxygen, thereby clearing them from impurities.

The gradual removal of the arc crystallizes the metal in the welding tank. Thus, seam is formed, which connects metal parts, and on its surface you can observe a layer of solidified slag.

To always hold high-quality welding, you need to learn how to maintain and move the electric arc. Too big arc provokes oxidation and saturation of molten metal nitrogen, it will sprinkle, and the seam structure will become porous and not strong enough.

Secrets of professional welders

The key to good work is the stable maintenance and movement of the electric arc. The too large arc oxidizes and nitrates the liquid metal, its drops are sprayed, and the seam becomes porous and not strong enough.

Stable arc stroke and fixed dimensions can be carried out by methods:

- Progressive - movement along the electrode axis. This movement will allow maintaining the desired length, which directly depends on the speed of melting the electrode. In the process, the length will be reduced at the time as the distance between it and the welding tank will grow. To avoid this, move the electrode along the axis by holding the stable length of the arc. Do not forget to synchronize the shortening of the electrode with its movement to the welding tank.

- The longitudinal - the electrode is mixed along the axis of the seam being processed longitudinally, thereby forming a thread welding roller. The thickness of this roller directly depends on the diameter of the electrode used, as well as the speed from which it moves. Usually its width is about 2-3 mm. It is already ready, but satisfied with a narrow seam. To create a solid and durable welding connection of one of the thread roller, it will not be enough. To enhance the seam during the move of the electrode along the seam axis, perform another movement by sending it across.

- Transverse - the use of this movement makes it possible to make the seam necessary width. It should be done by making oscillatory reciprocating movements. Their width should be determined "in place", based on the individual characteristics and design destination. The parameters of the oscillation also affect the location of the seam, the characteristics of the welded metals, etc. Typically, the width of such a seam is 1.5-5 diameters of the electrode used.

Over time, you will develop your own trajectory selection skills to move the electrode, but in any case, the movement should ensure the melting of the edges of the combined parts and the formation of the desired mass of the metal of the metal and the necessary seam shape.