How to adjust the carburetor from chainsaw Instruments

The speed and result of the work depends on the quality of the tool. If we talk about a chainsaw, then there are not so many details that need manual configuration. Nevertheless, there is one mechanism that requires constant control and accurate calibration is a carburetor.

Content

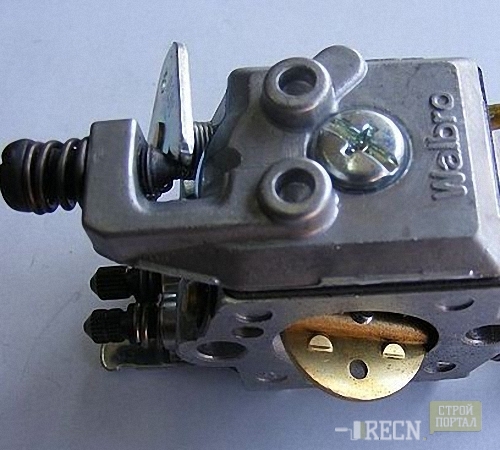

What is a carburetor and its principle of work

In modern gasoline engines, the carburetor plays, perhaps, the most important role. This device adjusts the fuel supply and optimizes it for the engine. As a result, the tool economically consumes fuel, and its service life increases significantly.

The carburetor consists of:

- air supply channel,

- diffuser

- sprayer

- float Camera.

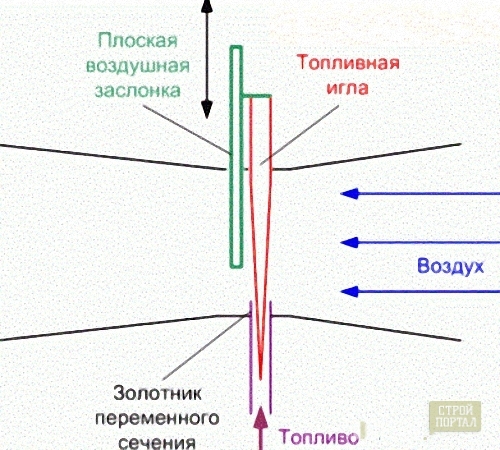

The fuel mixture for the engine is prepared as follows:

- fuel is fed to the float chamber, which adjusts the volume and feed rate of gasoline,

- further, through the sprayer, the fuel falls into the air supply channel,

- in the canal, gasoline is enriched with air, which speeds up the fuel combustion rate and saves gasoline consumption,

- the diffuser is a variety of damper, which is responsible for the speed and volume of the air supplied.

Various options for setting the carburetor allow you to use the same chainsaw in different modes. Incorrect customization of the carburetor, factory marriage or setting failure will result in a quick tool breakage.

Causes directly indicating the carburetor malfunction:

- The engine does not start either start and stalls, the reason can be just the "poor" fuel mixture.

- Fuel consumption increases and gases is highlighted much more, the reason may be a suspicious fuel mixture.

- After a few minutes of operation, the saw stalls, most likely the fuel mixture channel is scored.

Causes of the failure of the carburetor

Like any other technique, the carburetor flashes that the drive to the appearance of defects in the operation tool. In addition, there are other reasons affecting his work:

- Manufacturing defects. Not the most typical, but still the situation is. Regardless of the type and complexity of the repair, the product must be exchanged for a similar one. The presence of a marriage in one of the device nodes directly indicates that other malfunctions will also be.

- Carburetor wear. From a technical point of view, this device has no restrictions on the service life. But in practice, the carburetor works in a rather aggressive environment, which leads to the appearance of deposits on fuel and air channels. Over time, these sediments almost completely block the filing, as a result, the saw stops working.

- Low-quality fuel. Unlike the car where the carburetor is a sufficiently massive unit, a miniature device in a chainsaw. Consequently, it critically reacts to low-fledged fuel. In addition to obvious deficiencies, gasoline brand below 92a contain small particles damaging carburetor.

- Opening of protective casing. To avoid arbitrary change in settings, the carburetor is equipped with a protective cap. If it is likely to damage it during work, then the control screws are likely to change their position. As a result, the settings will be bought. This is the most typical reason that is easiest to eliminate.

- Wear of the feeding fuel of the mechanism. This reason arises in the event that the chainsaw work incorrectly. Frequent switching on and off the device leads to the erasure of the mechanism. Load at the start at times more than during operation.

Requirements for chainsaw

To avoid the tool breakage before the start of operation, as well as extend the service life, you need to use it correctly. Basic recommendations:

- A new tool before work must be driven by idle. This is done in order for all parts of the engine to get. Enough 30-40 minutes. If you give a load, non-rolled parts that are not yet fully treated with machine oil, will begin to straighten themselves, which will cause damage.

- After idling, you need to check all the basic nodes of chainsaws. There should be no soot, traces of oil. Pay attention to the smell. If the motor works correctly, the combustion process occurs inside, while the outer part of the case is not heated. Otherwise, an unpleasant characteristic smell of burned plastic and engine oil will appear.

- The next step is to check the chain. This action must be done every time before starting work. The chain is tensioning the tight as possible to the sagging to be minimal. In addition, pay attention to the securing chain, it must be firmly fixed along the entire length. If the hollow for a long time did not use, the tensioning mechanism will most likely weaken, and the chain will need to tighten. Schedules allowed for three or more months. If the defect is observed earlier, it means the tensioning device is marked.

- Check fuel and oil tanks. Gasoline has a property evaporate, and oil flows. Because of the limited size of the engine, it is difficult to achieve tightness, so after work it is better to drain fuel and oil into separate containers.

- The last moment is the adjustment of the carburetor. In many cases, the bad job of the tool is associated with the failure to fulfill the previous points. But if the problem did not leave, consider the calibration of the carburetor chainsaws.

How to set the carburetor chainsaw

If you saw a new one, up to one year, and it worked not very often, calibration is carried out without disassembling the device. To do this, you will need a screwdriver, gasoline reserve for one hour of work, and tachometer.

Most carburetors are equipped with three control screws:

- idling screw is denoted by the letter T, and is responsible for engine speed without load,

- screen increases, denotes the letter H,

- screen reduction screw is denoted by the letter L.

Advice: Not in all chainsaws, the marking is precisely this, so you should contact the technical passport and check. In addition, some carburetors are equipped with additional screws that are responsible for the diffuser and the float chamber.

The setting comes down to the adjustment of revolutions to the value specified in the technical passport. Rotate clockwise increases the selected parameter. Screws are equipped with a stopper. In the factory setting, turn them counterclockwise impossible. If the screw is left, then hit by a factory calibration.

- As a general rule, the reduction of revolutions leads to an increase in fuel supply and imposes a mixture. As a result, fuel consumption increases. The procedure must be performed if the saw is badly started or constantly stalls.

- The increase in revolutions enriches the mixture by air. This reduces fuel consumption. Excessive interaction of the mixture accelerates the engine wear.

- For accurate calibration, you need to bring down the settings. For this, the idling screw until the stop turns counterclockwise. And revolutions screws are installed in the original position until it stops.

- Then gradually rotate the screw increase. Turning should be done by 2-3 degrees. After changing the position of the control screw, start the saw and check the engine.

- It is necessary to find such a position when the saw starts from 2-3 times. This moment means that the mixture has become too saturated air and the gasoline is not enough in it.

- After experimental calculation of the restenuation point, the control screw turns 4-5 degrees to the left. This provision will be perfect calibration of specific chainsaws.

In the process of further operation and maintenance, the adjustment is performed using both screws, depending on the nature of the problem.

Important: Before starting the carburetor, you need to warm up the engine.

How to disassemble and clean the carburetor chainsaws

Unfortunately, not always the problem is solved by simple calibration of the carburetor. If the debugging did not help, then the problem is to clog the air and fuel channels.

1. To eliminate it, you need to fully disassemble the carburetor and clean it. For this:

- unscrew the protective cover

- remove the air filter

- turn off the fuel hose

- turn off the carburetor from the starter,

- remove the carburetor.

2. The next step is to inspect the carburetor:

- check the integrity of the case,

- check gaskets,

- check the heat insulator,

- disassemble the outer case,

- check the inside of the for mechanical damage.

Advice: in case of any defects, the spoiled part you need to replace and repair components are not subject to the carburetor.

3. The final step - washing parts:

- completely disassemble the carburetor, while the action better record if there is no experience in such work,

- clean fuel needle valve rag

- dry clean feed tubes from plaque,

- using a special flushing liquid carburetor wash all spares.

Advice: to better effect it is necessary to purge all the air feed tube, it will remove the detergent mixture and the residues adhering microparticles.

After complete drying of the spare parts, the carburetor is going. It is advisable to give at least a day that the detergent composition completely evaporated. He will not bring much harm, but it can negatively affect the first launch of the saw after repair. If the carburetor is gathering immediately, then the remnants of the detergent together with the fuel will fall into the engine. Since the cleaner is not intended for burning, it will change the color of the exhaust to the darker and will make it more toxic. There will be no other problems.

Another thing you want to know when disassembling the carbusopile carburetor is setting the needle valve petal. The petal must be installed and fit perfectly exactly, otherwise the saw will not start. For this take the blade from a dangerous razor and put on top of the petal. If it is spinning without problems, then installed correctly. Otherwise, it must be either bent or drown.

New comments

Add a comment

To send a comment you need authorize.

very valuable information. Nowhere could not find, and the specialists do not want to explain.