Formwork Mounting Technology Construction

Before proceeding to the construction of any building structure - a large building or a small room - it is necessary to pour a durable, durable foundation. And in this building process, the installation of proper formwork plays a huge role. What is a formwork, and what is the technology of its installation, will help to understand this article.

Content

www.kramos.ru/opalubka. Kammos - one of the leaders in the market of building formwork in Russia

Types of formwork

According to the method of operation and the possibility of repeated use of this design, three large groups distinguish:

- Removable formwork - removes, after the solution fully hardened. It is collapsible, so it is easy to dismantle and transferred to the next construction object. Ease of assembly and the ability to repeatedly use the same formwork and the construction itself and itself.

- The non-removable is that that does not dismantle after use, but becomes part of the erected structure. Basically, such a formwork represents the design of polystyrene or foam plates into which the solution is poured. It additionally performs the function of insulation of the erected parts, so it is widely used in the construction of the "Warm House" technology.

- The "floating" formwork is used when pouring the monolithic submersible foundation. From the boards prepare shields of a slightly larger than the planned height of the concrete structure. These shields are attached to the walls of the pit, dug through the foundation. On the perimeter to the shields, self-drawing is mounted only, rubberoid, you can cardboard.

According to its practical purpose, the formwork happens:

- Wall - for the construction of walls, vertical structures,

- Horizontal - for the construction of the foundation, ceiling,

- Formwork to create curved unusual forms of fused parts.

Formwork Mounting Technology

So, how is the formwork in practice is installed and used? If it is a removable collapsible formwork, then it is cheaper to collect from boards, bars or plywood low varieties. The main thing is that they are as long as possible. Stages of construction:

- To begin with, it is necessary to clear the entire platform on which the construction of the building is planned.

- To accurately place the area of \u200b\u200bthe construction and wooden bars to designate the angles of the area of \u200b\u200bthe area. These bars will be attached to the rest of the formwork.

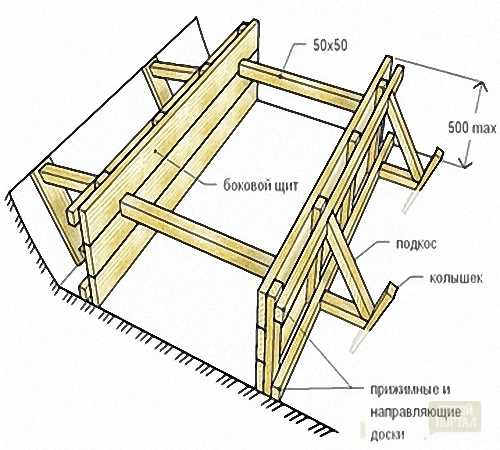

- Further, the distance between the bars is measured and according to it, the shields of the formwork design are assembled.

- Alternately, they are connected to the bruises of self-drawing or nails so that the bars remain with the outside of the formwork.

- In parallel, at a distance of the thickness of the future wall, another row of shields are built. Thus, a box frame is obtained throughout the perimeter of the site.

- Boat shields should be securely and firmly, so that with the expansion of concrete they do not break down and did not give a crack.

- A crushed stone or sand is covered in the finished formwork - it will protect the water from the solution with a soil from strong absorption.

- Also, it is recommended that the inner side of the formwork is noted either runneroid or film (using a siplair or self-tapping). It will save the foundation from the unwanted leakage of the solution.

- At the end, before the solution is poured, with the help of the level, the ideal evenness of the built formwork is checked in height, length and, most importantly, the vertical of the two rows of shields - they must be precisely parallel to each other.

All, removable formwork is ready, the solution is poured into it. If a further erection of the walls is planned, then the rods of reinforcement are inserted into a slightly hardened solution around the perimeter.

www.kramos.ru/opalubka. Kammos - one of the leaders in the market of building formwork in Russia

If this is a non-removable formwork, for example, from polystyrene foam, everything is much easier. The site is also prepared, the armature is clogged around the perimeter and there are no blocks from this material around, and then the solution is poured into them. This type of formwork allows you to build buildings in height, overlapping blocks to each other. One substantial minus of such a design is the price.

Construction of wall formwork

Wall formwork is harder. Two main types of wall formwork are distinguished:

- Small-out - going out of small plywood shields and is used to build country houses, yard buildings and indoor inland partitions.

- Large - applied in the construction of high-rise buildings. It is based on large plywood shields or metal sheets.

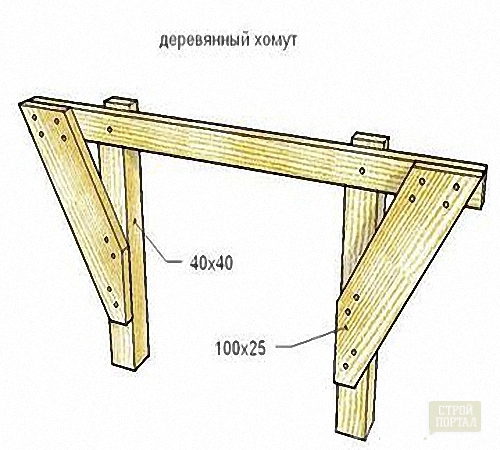

To build the walls, you must first construct a perfectly smooth metal frame, can aluminum, less often from bars - for thin walls or partitions. Just as for the foundation, this frame is a two-round. It is erected around the reinforcement in advance in the foundation. From the inside, it is laid out of plywood shields that are tightly adjacent to each other.

Previously, for additional sealing, the seams in the places of compound were drained with construction glue or resin so that the solution did not flow. And today a special plywood for formwork appeared on the building materials market. Her shields have a fastening fastening technology - one sheet is inserted into another. Thus, the formwork is collected as a designer. It is strong, hermetic and does not require the use of additional leveling bars, harnesses and other subframes.

A solution is poured into the collected formwork. Of course, for the construction of the wall formwork, they hold the calculated and sketched scheme, since the construction of walls requires a particularly clear and perfectly smooth formwork.

Installation of the formwork of floors

For the construction of floating overlaps, a similar method is applied as in the construction of walls.

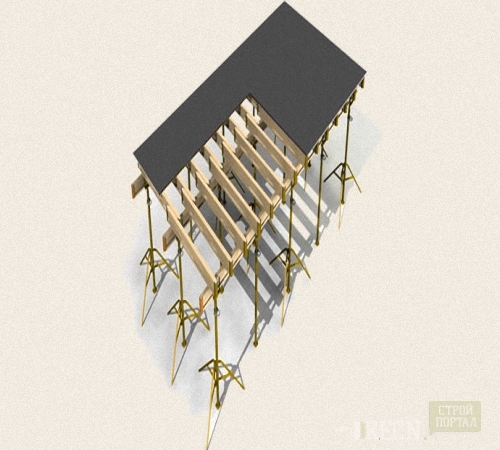

- Special building tripods are metal retractable racks that serve as a support for formwork - are installed throughout the installation area.

- Wooden beams are laid out on these tripods and fixed with ready-made walls. Cross beams are superimposed on these beams - the lattice turns out.

- On it all over the area, plywood or metal sheets are laid out - this is the bottomwork.

- Then, the lateral shields of formwork. They are strictly aligned in height and parallels to each other. For this process, you need at least two people. One - looks from above, so that the beams lay strictly horizontally, and the other - the bottom adjusts the height of the racks - tripod.

- You can also be fastened by the inner part with polyethylene for maximum tightness.

- The formwork is flooded with a solution of half. When he slightly grabbed, the rods of reinforcement and concrete are inserted on the perimeter completely.

Be sure to leave the opening in the formwork for the construction of the staircase, if it is a high-rise building.

Dismantling formwork

The analysis of the formwork can be started on the twentieth day, after the concrete is flooded. During this time, it dries and reaches about 70% of strength. She is filmed gradually.

- On the first day, all the elements from the corners are removed, since in these places the smallest power load.

- The next day, bars are dismantled, metal brackets that fastened shields from the outside.

- And only at the end, shields from the concrete surface are neatly removed.

The dismounting process is carried out carefully and neatly so as not to abandon the edges of the concrete formed foundation or overlap.

The better the formwork assembly and its alignment will be made, the greater the concrete structures.

And, of course, we recommend purchasing formwork systems from market professionals, such as part www.kramos.ru/opalubka.