Device monolithic column foundation Construction

Creating a ribbon foundation is an irrational occupation in the construction of small buildings that are characterized by a small weight. In this case, the most acceptable solution will be the device of a monolithic column foundation.

Content

What is the basis

The main elements of the column foundation are:

- sole (transfers the load from the carrier elements to the soil);

- a glass (is the basis for supports and racks).

The construction of pillars is made in places with maximum load:

- in the corners of the building;

- over long walls;

- in areas where the external walls come into contact with internal.

In addition to low-rise construction, a columnar monolithic foundation is applied when the carrier bed of the soil at a depth of over 3 m. In this case, it is ineffectively to build a ribbon foundation.

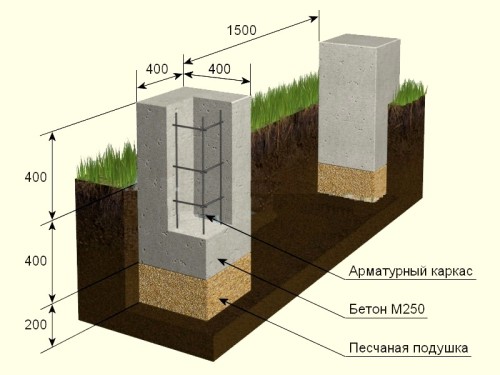

Usually laying the soles is carried out on the concrete slab, which is placed on the sandy pillow. When using metal columns, the top point of the foundation should be located at an altitude of 0.7-0.9 m above the ground surface. The columns themselves should be lower than floor overlaps.

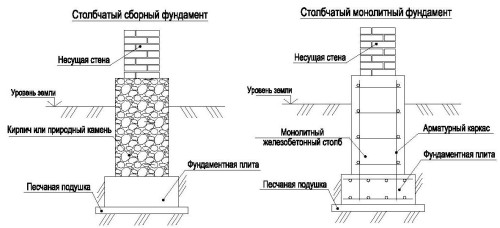

The monolithic column foundation under the column can be made from various materials:

- reinforced concrete;

- stone;

- brick;

- tree.

But the best solution will be the construction of a monolithic design with metal pipes and a frame that is poured with a concrete mixture.

Preparatory stage

At this stage, the following works should be performed:

- surface waters are discharged from the construction site;

- the reinforcement grid and frame elements are purchased;

- placed base;

- trenches (or pits under the poles).

Design work

The calculation of the monolithic column foundation includes a definition:

- accurate load on the base;

- the optimal number of support pillars, material for reinforcing and concrete.

To calculate the total load on the foundation, many parameters should be taken into account:

- the type of material from which the house is built;

- number of walls;

- roofing type;

- the presence of seasonal loads (snow, wind);

- the number of objects inside (fireplace, furniture).

To determine the optimal number of support columns, two formulas are used. With the first, the area of \u200b\u200bone sole is determined: S \u003d d² (the diameter of the widest part of the sole) * 3,14: 4. Suppose that the diameter is 50 cm. Then the area of \u200b\u200bone sole is equal to: 50 * 50 * 3,14: 4 \u003d 1962.5 cm².

According to the second formula, the number of supports is determined. To do this, the calculated load (for example, 180,000 kg) is divided into ground resistance (taken from a special reference book: for the sand soil, this indicator is 6 kg / cm²) and the area of \u200b\u200bone sole (1962.5 cm²). Based on the calculations carried out, the minimum number of columns is 15 pieces. Due to the fact that the columns themselves bear the load, 2-3 supports should be added.

The calculation of the monolithic basement fittings is carried out based on the sizes of piles. If their diameter does not exceed 20 cm, then 3-4 rods with a cross section of 1 cm. The total number of rods depends on the size of the support pillars. Vertical fittings binds with smooth 6 mm thick rods.

Marking of the base and digging trenches

In the design process, the drawing of the houses of the house indicating all carriers and inland walls. After that, begged on the marking work on the surface.

In the corners of the future foundation, pegs are driven. Checking the corners is carried out with a triangle. For measurements of distances used roulette. The correctness of the installation of pegs is checked by a diagonal method. Between the spicks installed in the corners, the line was stretched on the diagonal. Distances on both diagonals should be equal.

On the perimeter of the foundation, the twine is tensioned and driven by additional wedges (both on the outer and inside). The thickness of the columnar monolithic foundation by 12-15 cm should exceed the thickness of the walls.

The foundation is influenced by the level of primerization of the soil. Ring trench can be made both manually and mechanized way. If the trench dig over the entire perimeter, then it is better to use the technique. Their depth should exceed the level of soil freezing by 1-1.5 cm.

But it is more advisable to dig a pit in places where monolithic poles will be constructed. All wells must have the same sizes in both depth and vertical plane. The bottom of the holes falling asleep with sand and rubble, which are carefully compacted. Ruberoid or several layers of polyethylene film are placed on them.

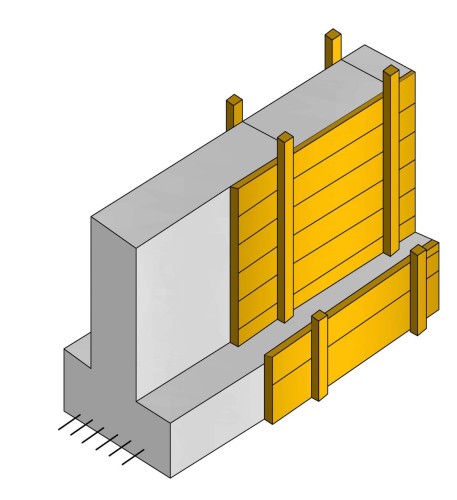

Device formwork

Before the implementation of formwork work should collect shields. For this:

- from the carrier elements (bouts) a box is made;

- shields are attached to the fights;

- the ribs of shields are covered with paint marks that show the placement of the axes.

To create a formwork for foundation, produce:

- installation and mounting panels at the bottom;

- mounting made of box;

- fixation of the lower part of the formwork to the base with the help of metal pins;

- application to the lower box of marks showing the location of subsequent prefabricated elements;

- assembly and installation of the following boxes.

Reinforcement work

After cooking the bottom of the well, a pipe is inserted through which a small amount of concrete is poured. The pipe is lifted by 12-15 cm, as a result of which the concrete solution spreads throughout the pit.

Next happens:

- final mounting pipe;

- bookmark in it metal rods with a diameter of 1-1.4 cm;

- fixation of anchors (when installing metal columns) and the pouring of the concrete mix;

- fastening the metal column on the anchor.

When applying the frame, the ends of the rod are produced out. It is thus the design binds and is all done.

Installation of anchors is carried out in two ways:

- In advance made holes. Anchor mount is performed using an adhesive mixture.

- Their installation to fill with concrete solution. Anchors come into contact with reinforcement.

To install anchors correctly, you should consider:

- their compliance with the axes of the foundation;

- distance between adjacent elements;

- height of the anchors from the concrete surface.

To simplify the installation process, anchors use a conductor-template on which there are holes under the fasteners. This conductor is mounted at a predetermined level, providing the correct location of all anchors.

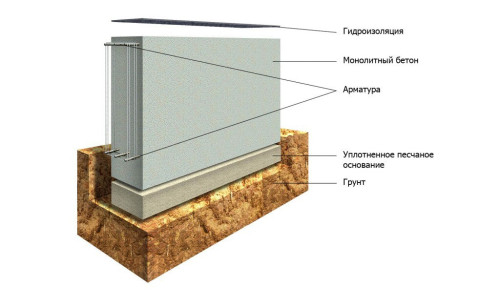

Concreting foundation

Before concrete work:

- the correct installation of formwork and reinforcement is checked;

- all existing defects are eliminated;

- cleaning of reinforcement and formwork from dirt and garbage.

The concreting process itself consists of two main stages:

- coating with a mixture of the base of the foundation and subds to the liner;

- pouring the top of the subsklonik.

The pouring of the concrete solution is made by layers, the thickness of which is 0.4-0.5 m. Each layer is subjected to a seal. A construction vibrator is used, which is immersed in a concrete by 8-10 cm.

Special attention is paid to sites near the walls of the formwork and in the corners, where additional sealing of the solution is performed. It is forbidden to touch the vibrator of reinforcement rods. The sealing process is considered completed when concrete ceases to settle, and cement milk appears on its surface. The vibrator is taken out in such a way that the emptiness arises in the concrete is uniformly filled.

In the implementation of concrete works (between the fill of the subsequent layers), it is necessary to take a break with a length of 40-45 minutes.

During the fill, the foundation should closely monitor the formwork. If its elements underwent deformation, the installation of additional fixtures is carried out. It is impossible to allow too large gaps.

The removal of the formwork is carried out after the complete pouring of the concrete solution. Moreover, when it dismantle, the concrete design should not be damaged. The process of removal of formwork is performed in order, inverse installation work.

For filling of the foundation, you can use ducklings. But the best solution is the use of clay, which is placed in several layers with rabbing.

Video about the monolithic base foundation device: