Vibrotol for paving slabs with their own hands Instruments

Handicraft production of paving slabs for their own needs should be carried out in compliance with technology. Quality components, vibrotols, plastic forms, drying racks are needed. But the vibrostol for paving slabs is not cheap. It can be made independently, saving to the means. We offer to explore the information about it.

Content

Principle of operation of vibrationtol, design

Vibrotol is intended for sealing a concrete mixture and displacing air from it. This allows you to get a homogeneous structure of concrete, which is important for high-quality tiles.

There are various designs of vibrationtol.

- Horizontal vibration. Such a vibrationtol (see photo below) consists of a bed suspended on chains (or straps of durable rubber) countertops and an engine with an eccentric attached to the shaft. The engine location is vertical, eccentric rests on the part of the hard frame of the table top and transmits it to move in a horizontal direction.

- Vertical vibration by shaft with eccentric. Allows the use of any asynchronous motor of sufficient power. The disadvantage of the design is the presence of wearing components (eccentrics and belt) and complexity of assembly.

- Vertical vibration with a vibrator engine. The simplest design without additional mechanisms, so that the vibrationtol (photo below can be made independently.

Answering the question of how to make vibrostol itself, we will focus on the latest version.

The main details of which consists of the device:

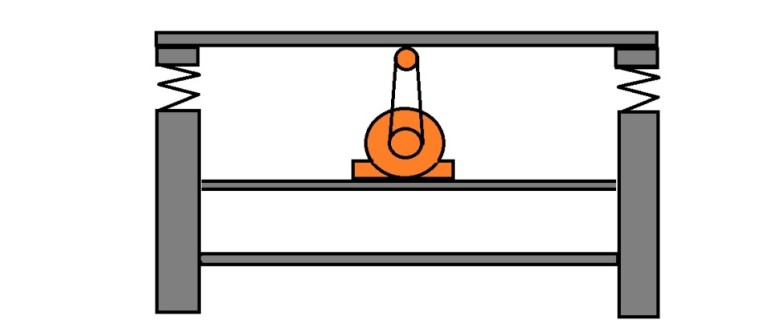

- Rectangular stand with springs fixed in the corners.

- Metal table top with sides.

- Electrical engine.

- Broadcast system with pulleys and eccentric.

The molding vibrotol for the manufacture of paving slabs works as follows: the rotation of the motor shaft with the eccentric attached vibration by the belt to the pulley and then - on the worktop.

Another option does not provide for belt transmission: an eccentric engine (or the finished vibration motor) is attached directly to the tabletop from the back.

It should be borne in mind: the molding vibrationtol can be used to knock out the finished products from the forms, for which it is necessary to install the nozzle with the holes in the form of tile on top of the countertops. In addition, it can perform the function of the sand sifter, for this design is complemented by a steel fine grid.

Vibrotol manufacture: Tools and materials

It will take the following to work:

- bulgarian with a circle for cutting metal;

- welding appack;

- roulette;

- profile pipe with a cross section of 40 × 20 mm;

- metal sheet with a thickness of 3 mm;

- corner 40 × 40 × 2 mm;

- steel springs.

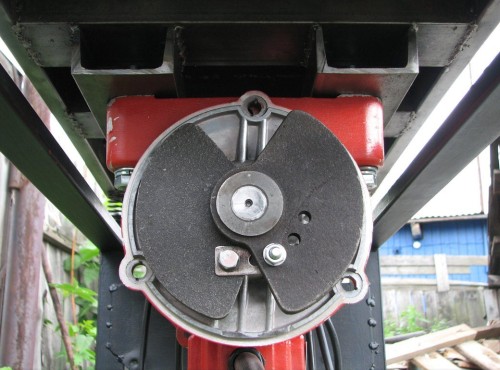

Springs are suitable from the moped or from Timing Kamaz. You can use a platform single-phase vibrator Vibrator VI-99E or VI-98E, the rotor of which makes 3000 rpm. The design of the vibrator allows you to choose the optimal frequency of vibration by changing the position of the eccentric.

Vibrotol for paving slabs with their own hands

After everything you need is at your disposal, you need to perform a working drawing of vibrationtol for paving slabs (by hand) with exact dimensions.

How to make vibrotole for tiles: phased instruction

Further work is made in such a sequence.

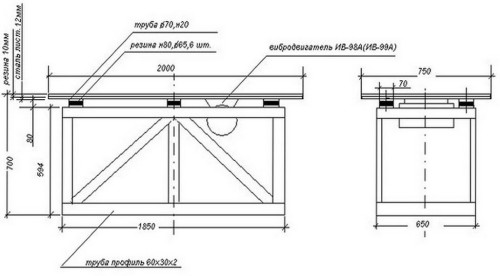

- From the profile tube (can be replaced by the corner), we make parts and weld them in such a way that the standard of the specified dimensions is obtained (for example, 1850 × 650 × 594 mm).

- At the bottom of the cabinets, we weld fifth and install rubber washers - for greater vibrotol stability during operation.

- In the corners of the beds, we weld the rings with a diameter of 50-60 mm. It is necessary that the springs are kept in place and did not pop out from the "nest".

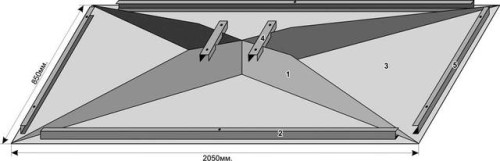

- With the help of a leaf iron grinder, cut the rectangular part for the table top.

- We enhance the tabletop: from the bottom side you weld the rigid ribs made from sheet metal or segments of the profile pipe.

- On the perimeter of the countertops of the Fresh Corner: it will prevent the shape of a solution with a solution during vibration.

- Confirm with welding to the bottom side of the table top two plates with holes: they are necessary for fastening the vibration motor. The dimensions of the plates, the distance between the holes must correspond to the parameters of the mating elements of the vibration motor.

- Plates are welded to the springs with screws to the corners of the table top from the bottom.

- Installation of springs and countertops, engine mount, wiring and control unit (on-shut-down buttons).

- The cabinet and the countertop must be painted.

Tip: Vibrotole should not be higher than 900 mm, otherwise the cabinet will not be stable. Too low (less than 750 mm), the device is not convenient to operate.

Vibrotol for paving slabs: video with constructor comments.

How to make a vibrotol for paving slabs using a regular asynchronous electric motor

If your disposal is a suitable asynchronous electric motor, it can be adapted for vibrostol. To do this, do the following.

- External parts are dismantled from the drive shaft.

- From both sides, the shaft is cleaned for welding bolts of type M12.

- Using the emery circle, bolt hats are processed and welded to the shaft.

- Two identical parts are made from the profile tube with a length of about 150 mm. With the edge of both parts that will serve as the eccentric, drill holes for fastening on the threads of the bolts.

- Eccentrics fix on the shaft with nuts. They should be oriented to one way. The threaded connection is grabbed by welding.

- The engine is installed in place and a test start is performed, while the tabletop must be forms with a solution for the manufacture of tiles or a replacement cargo. In the event that the vibration is excessive, the eccentrics will need to shorten by circumcalling the grinder. It is possible to increase the vibration amplitude by jumper welded between the eccentrics.

How to make a vibrotol intended for the production of a large number of tiles

- We make increased in size (in comparison with the project described above), countertop and an end.

- We divide the table top for three identical parts and spend the transverse lines along their boundaries. On the marked lines weld the plate for fastening two vibration engines.

- Synchronize the frequency of rotation of the vibration engine, adjusting the position of the eccentrics.

- Confirm the legs of the vibrotol to the floor using anchor bolts.

Now you know how to make a vibrotole independently and save money.