Make metal benches with your own hands Useful advice

For recreation in the country or in the household site, take care of the presence of benches. They are installed in the arbors and along the gardens. Considering that such specific garden furniture is operated in the open air, strict requirements are presented to benches. Their material and design should be reliable, durable, resistant to moisture, as well as aesthetically attractive. For such conditions, the metal is best suited: metal benches serve longer than others. We offer to familiarize yourself with the information on how they are manufactured.

Content

Metal benches manufacturing: Step-by-step instruction

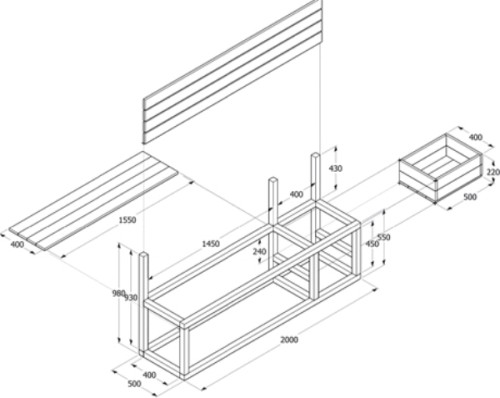

Before proceeding to the purchase of materials and directly to the manufacture, you need to perform drawings of metal benches. The size of the main parts on the overall drawing and the size of all parts in detail should be affixed. Details are numbered. After that, it is necessary to take care of the presence of materials, tools and devices from the following list:

- Bulgarian with cut-off and sharpening circles.

- Electric drill with drill set.

- Welding machine with electrodes with a diameter of 3 mm (optimally for a metal thickness 2.0 mm or more).

- Welder hammer.

- Electrolzik.

- Electrolake.

- Grinding machine with sandpaper.

- Kern.

- Roulette.

- Marker.

- Pipe bender: We are necessary for making a design with rounded forms of some parts.

- Profile pipes (rectangular or square sections). Such pipes are characterized by durability, and in addition, it is easy to mount any details. Such material wins compared to others by aesthetic appeal.

- Brussia 40 × 80 or 50 × 80 mm (for the device seats and backs).

- Hardware: Screws are needed with a length of 80-100 mm with a diameter of 6-8 mm (the selection depends on the parameters of the profile pipe and the bars), as well as the vehicle's self-tapping screws.

- Soil and enamel for anti-corrosion metal protection.

- Antiseptic and coating for wood processing.

Metal Cead Bench: Production of Parts and Assembly

From the harvested materials, parts are manufactured in the dimensions specified in the drawing. Ready details are numbered.

Important: When cutting a metal, it is necessary to take into account the thickness of the abrasive circle (the allowance is about 5 mm). The exact fit is performed using a grinder with a sharpening circle.

Next, the bench is made with your own metal hands with the next sequence of actions.

Metal frame manufacturing for benches

- For the device, the part of the profile pipe is connected in the form of the letter "P". The optimal height of the leg is 400 mm, the seating width is 400-500 mm. Accordingly, the height of the billets is reduced, given the thickness of the BRUSEV.

- Details are harvested for the back. The upper part bends under the radius of 300-400 mm.

- Using welding, the parts for the back are attached to the P-shaped billets. The bench with the back of the metal will be a convenient place to relax, if the back will be attached under a stupid angle to the seat. To implement it in practice, the bottom of the parts should be bent. The height of the back is usually 0.8-0.9 m.

- The finished parts of the bench must be joined by long pipe segments: two are attached horizontally - for the seat of the seat, and two more - vertically, in the backrest area. In order for the design of the bench for the cottage from the metal was more rigid, it is recommended to weld the extra elements between the legs. Strengthen the Bench Diagonal Details.

- In the lower part of the metal frame, as well as on the side and in the backbone area, you can breed forged elements in the form of a plant ornament.

- "Pigs" are welded to the legs so that the bench is resistant even on the ground.

- Metal parts benches are processed by primer and covered with enamel.

To your attention a photo of metal benches made with various stylistic solutions.

Production of the seat and backs benches

How to make a metal bench comfortable? The best material for the device seats and backs is wood. It does not heat up in the summer and not cooled in the fall. In order for a bench well and lived for a long time, you need to do the following.

- Pre-prepared and well-dried boards or bars are collected in size specified in the drawing.

- Wooden parts are processed by electrourub and grind. After careful cleaning from chips and dust, wood is covered with protective equipment and decorative enamels.

- To the short parts of the metal skeleton of the seat and backs with screws with washers and nuts are attached to the sizes of 50 × 50 mm. For this, the holes are drilled in profile pipes.

- Wooden parts for the back and seats are fixed to bars with self-tapping screws. In order for the screws of the screws to be recessed, drill holes at the top of the relevant diameter drill.

- We disguise hardware putty, selected in color.

After that, the bench can be installed in place. By the same principle you can make a table for a gazebo.

Some nuances of how to make a bench do it yourself from metal, will be shown on the video.