Board floor. Sounds of laying, leveling and repair Floors

Wood in construction is already applied long enough. Even today, she does not lose its popularity, despite the emergence of new modern materials. For example, wood is often used as an outdoor coating. Especially good flooring out of wood looks in a private wooden house. It has many advantages. Of these, durability and environmental friendliness are especially allocated. In addition, such sex is very warm and easy to care for it. How to mount boarding coatings next.

Content

Stages of mounting

The laying of the board is recommended to do at the end of the heating season. It is important that normal air humidity attended during the work. Such conditions will be completed if there will be no precipitation during the week.

When the board of milking floors, you must consistently perform the following works:

- Select the material.

- Put on the base of lags.

- Produce flooring board.

- Planing and cleaning the floor surface.

- Installing plinths.

- Ventilation arrangement.

- Finish finish.

Choosing practical wood

It is very important to choose the material correctly. For this purpose, coniferous woods are considered one of the best budget options. They are distinguished by durability and wear resistance. If the floor is covered with varnish, without pre-staining, then additional requirements used by the material are its beautiful texture and high strength. Here you can offer a nut or a red tree. If the income does not allow the use of expensive wood species, then you can stop your oak. It is also worth paying attention to the t-shirt of the coniferous wood of wood. It is characterized by good operational properties and it looks good.

In any case, the material must be well succeeded, but not reheated. It should not have any defects. In addition, before the floors, the boards from the bottom must be treated with the compositions that protect them from rot, fire and insects. From above processing material by these means it makes no sense, because this side will be covered with varnish or paint.

Materials

The following materials will be needed for the adobe device:

- Lags of 5/5 centimeters 3 meters long.

- Special substrate for sound insulation.

- Heattel.

- Nails, selflessness.

- Anchor bolts.

From the tools for laying floors can be useful:

- Saw either electrolybiz.

- Building level.

- Hammer.

- Small power drill or screwdriver.

- Nail holder.

- Axe.

To lay wooden floor, it is better to start when all the basic works will be completed, i.e. Already after installing doors and windows, as well as the final decoration of the walls and the ceiling. One of the important factors to pay attention to when installing is the humidity of the indoor air. It should be no higher than 60%. Too low value of this indicator is also unacceptable.

Floor laying methods

When all materials and tools are prepared, proceed directly to laying floors. This can be done in different ways. Consider a few of them.

Lagam board floors

Lags are bars of 5 × 5 or 4 × 6 centimeters. They should be aligned in a horizontal surface with a construction level. At the same time, a soundproofing substrate is placed under each bar. On the concrete base, they are attached to anchor bolts or screws in such a way that there are about 60 centimeters between them. After installing the lag, you need to make sure that they are all at the same level. In order to check this, you can use simple smooth bar, putting it into several neighboring lags.

The procedure for installing lag is important. The first mounted those that are located near the opposite walls of the room. At the same time, they must be placed perpendicular to the output of the beams of light from the windows. In the corridors, where there are usually no window openings, the lags are installed across the movement. Thus, the flooring boards will be laid along.

When all lags are in their places, you can start the installation of the planks. These works are customary to start with the angle of the room. The first row is located with a tongue to the wall. It is important to leave the gap of about 1 centimeter. This will be enough to compensate for possible deformations of the floor covering during operation (drying or expansion). The following boards are stacked in a checker order, i.e. With the displacement of the relative first row. This allows you to reduce the amount of excess material. Boards are adjusted with a small trimming of a bar and a hammer. After a dense fit, they are attached to lags on nails or self-tapping screws.

Laying of female floors on adjustable lags

This option is suitable for cases if the base of the floor is uneven and has significant height differences. Thanks to this method, you can save time for installation, reduce the load on the supporting structures, pave the necessary communications and make not bad thermal insulation.

Assembling floors in this case is as follows:

- In the lags at a distance of approximately 40 centimeters, holes are made.

- They screw the rack bolts.

- Then the lags are placed on the basis. At the same time, between them should be a distance of about 50 centimeters.

- Lags are aligned with level and attaching dowels to the base.

- Excess parts of the racks are cut.

- The boards on top are lined up by the same scheme as in the first version.

Laying with shoes

There are different types of shifts:

- Shot-bracket.

- Wedge shy with a movable bracket.

- Locking shy without a bracket.

For connecting boards, wooden wedges are required with a cone angle of 15-20 degrees and a thickness of the same as the size of the floor board. One of them will perform the role of laying, and the second (from solid wood) will become a "working" retainer.

Laying with the help of shifts is performed as follows:

- The first board is strengthened.

- Next to her are tightly stacked another 10-15 boards.

- The last plan is set at least two complications. At the same time, it is important that there is a distance in which the narrow side of the wedge is placed between the boards and retainers.

- With the help of a hammer from one compression to another, wedges are sealing. It is important that there is no clearance between the boards, i.e. It is necessary to ensure a dense fit of the planks to each other.

- When the boards are connected into a ray, nails are clogged at an angle. Their caps are "taken out" in the wood.

- The ends of the boards must be located on the lags, not allowing the formation of gaps. After laying all the slats, the gaps between them and the wall are closed by a plinth. In addition, ventilation holes are performed in two opposite corners. After installation, it should be closed with stainless steel grid.

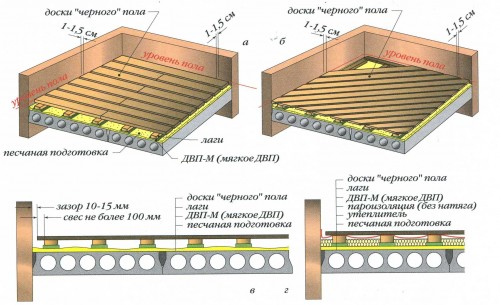

Paul overlapping beams

In this case, beams are used as carrier elements. Such an outdoor coating has its advantages and disadvantages. Benefits include what it is reliably isolated from the soil. In addition, such a design strengthens the construction framework. From the disadvantages it should be noted that the beams are tightly attached to the base of the house, because of this, all oscillations and sounds are transmitted from the floor to the walls of the construction. Therefore, the wooden floor is not recommended to arrange directly on the beams of the overlap, i.e. Using them as a lag.

To reduce the level of noise, you can use materials that can repay vibrations, for example, insulating rubber gaskets or felt, impregnated with antiseptic. Although it is more important to establish an additional lags across the beams, which should be laid special gaskets that absorb noise.

In some cases, over the beam overlap has to arrange a draft floor. It is usually needed to support heat and sound insulation. Two types of draft coatings distinguish:

- Promfort.

- Set.

The prosest board floors are solid flooring from boards, jacket and bar. It usually stacked over the beams of the attic floors. The material thickness is selected depending on the aggregate used. Between the boards are connected "in a quarter", after which they are nourished to the beams.

A typical draft floor is distinguished by the fact that the boards and plates of small length are stacked on the nailed bars. At the same time, they are rally (recruited) in a quarter.

Floor grinding

Grinding is needed in order to align the wooden flooring, give it a complete view. To do this, you can use both manual and floor grinding machines. Before starting these works, the entire garbage should be removed from the surface. It is still necessary to carefully inspect the floor coating. It is necessary in order to make sure that there is nothing on it than you can damage the abrasive tape (brackets, nails hats, etc.). In addition, the angles should be viewed for the presence of chosel and irregularities. All defects need to be eliminated before the floor is polished.

For grinding, not only the instrument will be required, but also protective equipment (mask, glasses, headphones). During operation, in order to prevent the chips, the grinding machine must be moved along the flooring. At the same time, it is impossible to allow a strong pressure to the tool. Usually work starts large, and finish with small skirt.

Floor staining

Before painting the floor, it should be well adding. Staining is carried out both with a brush and sprayer. When the floor is dry, the paint will become lighter than immediately after applying.

In order to make the coating a more beautiful shade, a transparent varnish is applied. For this purpose, it is recommended to use acrylate forces soluble in water. Such substances are easily applied, do not smell, quickly dry and much safer for health than nitrolakes. Typically, the floor is covered with two layers of varnish (the second is applied two hours after the first).

Repair of board facilities

Repair of the board can be carried out without much difficulty independently. Consider some of the most frequent defects found on such a coverage, and possible ways to eliminate them.

- For example, because of the drying of wood between the boats can form gaps. To solve this problem, you must carefully with the help of a nail to pull the nails, which hold the boards on the lags, and then remove the old flooring. Next, drunk and fiddled strips are replaced with new ones.

- If there are boards in good condition, they are not replaced, but stacked again. In any case, the material must be laid tight towards each other. Therefore, even if all the planks are good and without visible defects, you may need additional. If there are small cracks, it is recommended to close them with a putty.

- Very often the boards begin to spring. To solve this problem, it is necessary not only to rebuild the entire floor, but also add a few more lag for stiffness.