How to make a sunflower oil olive with your own hands paints and varnishes,Useful advice

Sunflower oil belongs to plant types of this raw material. It has long been used for different purposes, including for the impregnation of wooden surfaces. Since the oil in the raw form did not supply the proportionate function of the wood coating, then it began to boil. Welded sunflower oil began to call - Olife.

Content

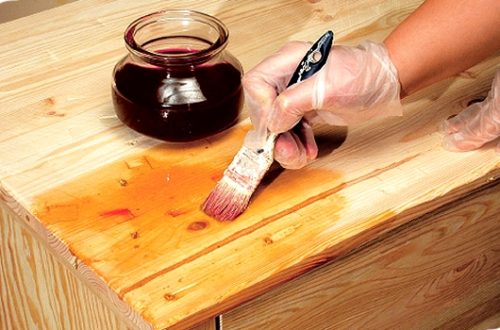

Olife from sunflower oil. General

Since ancient times, Olifa was used as protection of wooden structures. The facility covered and impregnated with the oil was operated longer than the usual, since the olive protected it from rotting, tree insects and weather factors. Over time, other, more efficient protective agents appeared on replacing the boiled oil. In this regard, the range of applications of Olifus narrowed. It began to cover wood indoors, as well as for processing porous surfaces under painting. In addition, the Olif can often be found as the main component for oil paints.

Classification Oliffs

To better understand the nature of this material, it is important to distinguish its characteristic features. With the movement of progress, various additives have begun to add various additives, designed to improve the operational means of the application surface. It is additives that played an important role in the formation of types of boiled oil.

Among the total number of protective remedies from Olifa, the following types can be distinguished:

- Natural Olife. To make such a mixture, use vegetable oils, such as: hemp, tung, sunflower, linen, etc. They are treated, and sometimes mixed with each other, combining in different proportions. Since in its composition, they practically do not contain solvents, this species is most environmentally safe, since it practically does not release toxic substances. For example, oil is used directly for the preparation of flaxseed oil and, made on its basis. Such a olif has a bright transparent look. For example, the olife, welded on the basis of hemp oil, also looks transparent, however, has a less dark outline. For its preparation also use Sikkativ.

Sunflower Olifu also refer to this kind. However, note that such a olif will stick much longer, and will give up linen and hemp olife with its durability, water resistance and hardness. Even after the day after applying, it has a slightly sticky structure. - Semi-human oil. In the cooking of such oil do not use surrogates and mineral supplements. The composition includes: 55% compacted sunflower oil, 45% of volatile solvents and 5% of sequivations. Such a solution is of deep heat treatment, after which they give to cool. The olif has a transparent structure of light brown. This allows objects covered with such an oil, possess high indicators of moisture protection, hardness and weather resistance. It is often used in a pair with other finishing materials to achieve excellent painting qualities. In addition, the semi-natural olif glitters very well and absorbed into almost any porous surfaces.

- Combined Olife. In the process of producing this mixture, drying and half-having oils are involved, which are mixed and then dehydrated. As a result, it turns out a polymerized product, which is used mainly for the manufacture of densely chopped paints. On the complete drying of this type of olifa will need a little more than a day.

- Shale Olife. Refers to an inexpensive type of protective coating. It is a dark fluid that is used in the production of a dark spacker intended for dilution of various types of internal and outer paints. To achieve the desired consistency - oxidize shale oils, after which they dissolve them in acid. Such a olive has good performance indicators from climate change, and for complete cooling it takes only 24 hours.

- Synthetic Olife. Have a very dark structure, due to oil refining products contained in the composition of products. It also includes waste obtained in the production of synthetic rubber and coal. The release of such olifa is limited because it has a fairly low quality and sharp smell. The use of this mixture is unacceptable inside the residential premises and on wooden surfaces.

As you can see, the choice of olif is great enough. Each of them consists of various materials, and serves to protect all the roots of coatings. However, the preparation of most of them is impossible at home, because it will require the presence of raw materials that simply cannot be purchased. The easiest way to make a natural olive from sunflower or linseed oil itself.

Purpose of Olifai

As you can see, the nature of the olifa is quite wide and diverse. One remains unchanged - its purpose. The main function of the Olifa is the protection of the coating from the external influence of various factors.

Olife is designed for use in the following areas:

- the primer of wooden, metal, plastered bases inside and outside the premises;

- giving brilliance to old subjects;

- production of mastics for various types of paints (emulsion, oil);

- breeding densely paints;

- as a masonry for window structures.

Rules for storage and use of Olif

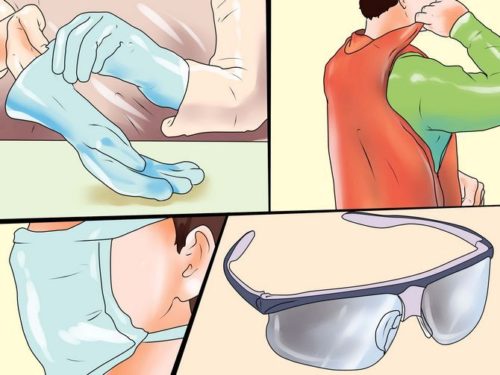

Since the oil is made of oil, solvents and other additives, it is attributed to fire-hazardous materials. When working indoors, it is necessary to establish forced ventilation, if natural ventilation, for example, is not possible. Provide yourself with all means of protection to avoid getting mixes to open skin. Get yourself with glasses, gloves, and overalls. Since some types of olifa have a rather sharp smell and toxic, it is better to produce work in a respiratory mask.

Make sure the container in which the oil is located is tightly closed. This will protect it from the impact of humidity and ultraviolet rays. Make sure that there are no electrical appliances and other potential foci of ignition near. In case the Olife thickens, dilute it with any solvent for oil paints in the ratio of 1:10. Follow the storage and operation rules. Do not forget also about safety equipment.

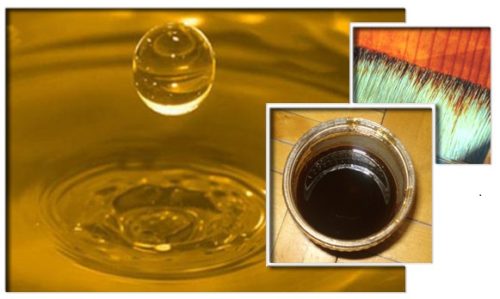

Independent manufacture of natural oils

Now, when we studied all the features characteristic of this material, you can pay attention to the independent production of Olifai based on natural oil at home. Frequently invented protective coating has various preparation recipes that have a similar character. Further in the article we will try to explore one of the ways of cooking the oils from sunflower oil. We chose the sunflower oil as the main ingredient, since it is more accessible and cheaper, compared, for example, with flax or hemp.

Subscribed tools and materials

Before proceeding to the independent manufacture of Oliflates, it is necessary to arm well and prepare, then the work will pass quickly and easily, and the result of you will undoubtedly please.

To make a homemade oil from sunflower oil, we advise you to purchase the following set of tools and materials:

- heating element (electrical, kerosene or gas stove);

- metal capacity (pelvis, bucket, saucepan, cauldron, boiler);

- felt march;

- protective clothing, glasses, gloves, respirator;

- manganese peroxide, rosin;

- sunflower oil, siccative.

Such a simple set will simplify and speed up the manufacturing process and cooking of natural olifa. Do not forget about safety technology. Boiling oil is heated to high temperatures. Get high-quality protective facilities in order to protect yourself from getting hot mixes on the skin and open mucous membranes.

Preparation of the base for sunflower oil

Before proceeding with the main cooking process, it is necessary to pre-prepare oil. Regardless of how the oil can be boiled, the oil must first be treated under high temperature. This is necessary in order to remove water from sunflower oil, and oxidize all impurities in the mixture. Such procedures are mandatory. Without these preliminary actions, it is impossible to cook high-quality Olif, whatever the boards you would use.

To prepare sunflower oil to preparation directly, the oils are applied as follows:

- Fill oil into a metal capacity by 60% of the total volume. Put everything on a slow fire.

- Heat the oil until the foam starts on the surface. This means that the mixture was heated to 110-120 ° C and the process of dehydration began.

- After the beginning of the appearance of foam discharge, continue to cook the mixture at 170 ° C. Depending on the volume of the container, the oil is warm about 3-5 hours until the water is completely evaporated.

- Increase temperatures up to 260-280 ° C. After some time, you will notice that dark flakes will be distinguished from the oil.

Useful advice: To understand that the mixture was heated to 280 ° C, lower a pigeon, goose or chicken feather into it. If the edges of the pen began to twist, then the mixture is ready for the following actions. If the pen is not deformed - continue to warm the mixture until readiness.

- Disconnect the fire so that the oil is cooled. After you have cooled a mixture, pull the gauze in the containers of an identical volume. Strain through this filter cold mixture.

Cold Varka

The first way is conditionally accepted to call "cold", although it is carried out under the influence of high temperatures.

To make the olif, the method of cold cooking come as follows:

- Mix the sequivator with the oil base in the same proportion. Note that the number of the sequence depends on the amount of oil, an average of 5-8% of the total volume.

- It is necessary to heat the filtered cooled base up to 120-150 ° C.

- Start stirring the mixture by simultaneously adding a sequivator.

- In case of abundant pencil divisions, accelerate the stirring. At the same time, keep in mind that the speed of the administration of the sequence is better reduced.

- When the entire sequing is entered, and the foam ceased to stand out strongly, turn off the fire. Leave the mixture cool.

Hot varka

The second method provides for a slightly different production technology of oils from sunflower oil.

For the manufacture of natural oils by the method of hot cooking, use the following algorithm:

- Distribute a sequivator with an dehydrated oil base in the same proportions.

- Heat the filtered mixture to 170 ° C, that is, before the appearance of foam.

- Gently add a mixed sequiva (about 2% of the total volume).

- If the entire sequing is entered, and the foam is not released, continue heating to a temperature of 280 ° C, constantly stirring the mixture.

- Support the temperature for 4 hours so that the future olifa acquire the desired viscosity.

- Give the olife to cool.

Expert Council: If you want oil faster dry, add a mixture of zinc, calcium and manganese into it. Cooling rate, in this case, will decrease by 2.5 times.

Replacing Olife

It happens that the possibility of buying or self-preparation of olifa is absent. In this case, it is necessary to choose a similar tool that will perform similar functions. This will not require special skills and technologies.

To prepare analogue of olifa, come as follows:

- Mix the ingredients in the following proportions: casein (100 pieces), greased lime (25 parts), soap solution (15 parts).

- During the knead, add a gradually turpentine (30 parts).

- Dilute the mixture with water to thick consistency (similar to the oil).

- Add a bit of ammonic alcohol to the solution, because there is a precipitation of casein lime.

The result is a mixture, no worse than the oils, and perhaps even better. Such analog will be cheaper, while the quality will be higher, and the time of the mixture is much smaller. The scope of the mixture is the same as in natural oil.

We hope this article we maximally disclosed the question associated with the independent manufacture of natural oils from sunflower oil at home. Since the cooking process occurs under the influence of high temperatures, then do not forget about harmful allocations that can adversely affect your health. Always use protective equipment, then the cooking will pass quickly and painlessly.