Lighthouses for screed. How to install lighthouses Floors

Any base for flooring has irregularities. In most cases, the alignment of the surface is carried out by means of a screed device. Our article will talk about how to set lighthouses under the tie.

Content

Preparation of the foundation

In order to install the lighthouses and correctly fuel the screed, it is necessary to carry out a number of preparatory work.

Elimination of defects and dust

At the initial stage, the defects of the draft floor are eliminated: detachments, bugs and large cracks. Close up all the gaps that are between plates of overlapping. The concrete solution is poured into cracks, rolls up with a spatula and dries. The slots do not need to be perfectly alumped with a solution because the screed will be poured.

After eliminating large defects, the draft floor is cleaned from garbage. To remove dust in the corners and joints, you should use the vacuum cleaner. If the base is covered with smooth shiny propellants, then such sections must be cleaned with a brush for metal. Otherwise, in the future, the screed can be deformed.

Similar to surface

After cleaning the concrete base from dust, the surface is used. The composition is used that is designed for a strong absorbent surface. It is impossible to acquire primer, the instructions for which it is indicated that the pouring of the screed can be performed on a low surface.

Protecting the draft floor is made in two layers. The second layer of primer is applied after complete drying of the first. It is not recommended to use a roller. If there are small irregularities, they will not cover the primer. Therefore, it is better to use a wide brush.

Laying of damper tape

Thanks to the damper tape, cracks in the screed in the process of drying out are not allowed. Sticking the material will not cause special difficulties. The protective layer is removed, and the tape is pressed against the wall.

Subsequent pieces of ribbons are stacked and jointed. When climbing the corners, the material cuts into the lower part, where it will dock with the floor. Installation of the damper ribbon is required when the floor is aligned with the "wet" screed.

Determination of the zero level and the amount of material

Before laying beacons under the tie, determine the zero level. For this, the following works are carried out:

- from the surface of the floor, 1 m is measured and the first point marks on the wall;

- after this point, a smooth horizontal line is carried out;

- in several places from this line, the distance to the floor is measured;

- it is determined by the highest and low points;

- the highest point is a guide for a zero level;

- zero level is 3 cm higher than the highest point;

- this suggests that the minimum screed thickness will be 3 cm.

Sometimes you can encounter the fact that the highest point can be in the center of the room. This is checked by pulling the fishing line from one wall to another and diagonally diagonally. When this point is detected, one of two ways come:

- the new zero level is determined;

- with the help of hammer and chisel, the concrete base in the center of the room is considered.

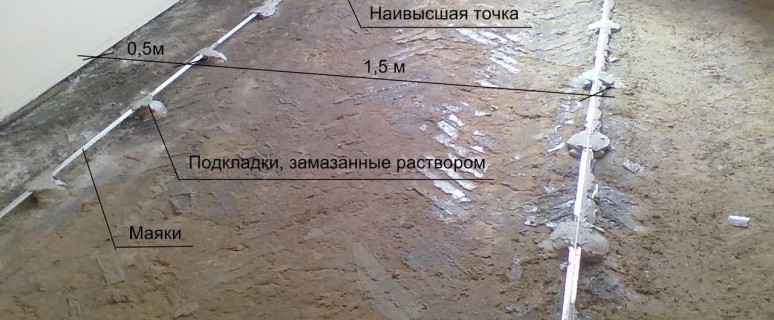

The calculation of the number of beacons for the screed is made, based on the distance between the walls and the length of the rules that the laid concrete solution will be resurrected. The montage step of beacons also depends on the length of the rule. So, if the tool will have a meter length, the distance between the beacons should be 65-70 cm.

Mounting work

Installation of lighters for a screed directly depends on the surface alignment technology used. Three main technologies distinguish:

- concrete coating;

- self-leveling floors;

- dry screed.

Lighthouses for concrete coating

When using a concrete solution, as lighthouses can be used:

- plastering profiles;

- profiles intended for installation of plasterboard;

- steel tubes;

- wooden bars;

- cement mortar.

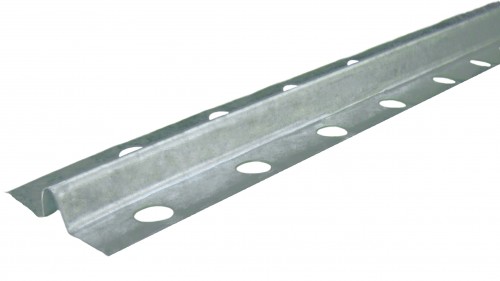

Plastering profiles

Plastering profiles are most often used as beacons for a concrete screed. They are especially indispensable when the floor alignment occurs in a small room, and the thickness of the floor screed around the lighthouses does not exceed 3 cm. Otherwise, the concrete can get a profile.

The technology of installation of plaster profiles involves the following work:

- during the location of the lighthouses, self-tapping screws are screwed;

- between them stretches the fishing line, which is located on the zero level;

- on the same line, small bugs of concrete solution are stacked;

- profiles are pressed against the solution and spread with a fishing line.

Plastering profiles pressed to the solution very carefully. Since it can be easily rumbled and break.

Profiles for plasterboard

This material has a P-shaped form. When laying a profile, the base should be on top and rely on the self-tapping screw and concrete solution.

Installation of beacons consists of such steps:

- at a distance of 0.4-0.5 m, screws the screws in the dowel;

- self-tapping screws must be in a dowel by more than 50% of their length;

- screwing the screws along the wall occurs taking into account the zero level;

- between the self-drawing stretches the fishing line;

- adjustment of the horizontal level of the fishing level is carried out by screwing / disintegrating the screws;

- near the screws is carried out by laying a solution;

- profiles are mounted on a solution and self-tapping screw;

- using the level, the correctness of the installation of lighthouses is checked;

- profiles lay concrete on both sides;

- after drying, the solution is embarking on the pouring screed.

Instead of self-tapping screws, you can use a brick battle or just make slides from the working mixture.

Steel tubes

These beacons are the most optimal option for the arrangement of rooms that differ in the large area, as well as when pouring a heavy screed. Pipes are characterized by maximum strength and are not deformed.

There is the following beacon setting:

- on zero level stretching the fishing line;

- in a straight line, slides from concrete are stacked;

- pipes are pressed into the solution;

- their horizontal location is checked.

If the pipe is above the specified level, then it must be pressed into the solution. If on the contrary, the mortar is placed under the lighthouses. After the proper installation of the pipe is coated with a solution that should be seized. After filling and drying the screed, the pipes are removed, and the holes close.

Wooden bars

Nowadays, this technology is practically no applied. As lighthouses protrude rains, over 3 cm thick. To create a single horizontal plane, wooden wedges or lining made from another material are used.

Before the installation of installation works, the timber is wetted with water so that it does not absorb moisture from the cement mortar. Lighthouses are covered with concrete. After grappling the solution, the bar is extracted, and the holes are poured with concrete.

Cement mortar

This method of montage of lighthouses is characterized in that after the work, nothing needs to be extracted. What significantly reduces the duration of the fill of the screed.

The process of installing beacons itself is as follows:

- in the base of several rows screws screws;

- a fishing line is stretched between them;

- the laying of the solution occurs along the strained fishing line;

- this work involves creating a low wall;

- the upper part of the wall is a lighthouse.

Lighthouses for bulk sex

This coating is characterized by the fact that it itself is distributed on the floor, fills the recesses and levels the surface. Lighthouses are used for the liquidating floor;

- stittle lights with tripod (references);

- saws.

Reperas

The reper is a design that has a rod (central) and three legs. Due to the rod that can move up and down, the specified surface level is set. Before installing the references, the entire surface is ground. The distance between the trenoogy pin beacons is 0.9-1 m.

Selfless

Of course, the references are very convenient in use. But if there is no desire to spend extra money, the lighthouses for the bulk can be made independently. This will require conventional screws. Self-tapping screws in a dowel. Between them stretch the line or punched. After the fill of the bulk sex, the screws can be unscrewed.

Lighthouses for dry screed

As a lighthouses for a dry screed, a profile is used with which they create a frame design for drywall.

It is not recommended to use a subtle material for two main reasons:

- the profile is prohibited to be fixed with self-drawing to the base, which consists of a layer of waterproofing;

- to secure it, you will have to acquire and carefully install additional fasteners.

For this reason, the most optimal option will be the use of plasterboard profiles of the P-shaped-shaped-shaped width of 60 mm and a thickness of 27 mm. Their styling is carried out by sharp corners. For reliable lighting fixation, clamzit is usually used, which is embanked both into the inner part and between the rows of lighthouses.

There is a rule between profiles. Using the level, the horizontal location of the beacon is checked, as a result of which the excess material is removed or the missing clay is added. After the device, the dry screed lights are not removed.