How to drill tiles. Practical guide Tile

After the main stages of repair in the bathroom or in the kitchen behind, it remains to put the furniture, strengthen the hooks for towels, soaps, shelves, and so on. This is where the question arises: how to drill ceramic tiles? It is important that it does not split. Moreover, it is often necessary to make several holes in one tile. In order not to spoil the facing material before proceeding to work, learn the following recommendations.

Content

What tools can be used to drill tile

Depending on the hardness of the tile, the drilling can be carried out with:

- perforator with the drilling mode "without impact";

- electric drill;

- hand drill (for small holes);

- rechargeable or network screwdriver.

How to drill a tile so that it does not split: the basic rules

- You should try to avoid drilling holes near the edge of the tile. It is necessary to retreat at least 15 mm.

- If the tile is not yet glued - it is soaked in water for 30 minutes. This makes the material softer and reduces the risk of splitting.

- The tile fastened on the wall or on the floor during drilling is recommended to be periodically enabled with water. This prevents the formation of chips.

- If possible, the hole needs to be located between the tiles. This makes drilling easier and safe.

Some tropping tile drilling

How to drill tiles on the wall, not afraid to spoil it? This question is especially relevant if there is no replacement tiles. At the very beginning of drilling, it is already difficult to consider:

- with a glossy surface, the drill snorkels towards even with a slight pressing tool;

- the facial side of the tile is usually more hard and durable;

- conventional drills for concrete and brick are not suitable for work;

- ceramics has poor bending strength, which increases the risk of splitting when a tool is pressed.

To reduce the risk, you should use some tricks.

- The glossy surface at the drilling point must be scratched with a core or other sharp tool. If you break the outer smooth layer of tile - the drill will not slip.

- Cross-closets are placed in the place of drilling. This method will help to avoid the "enzysting" tool.

- If a large diameter hole is needed (10 - 15 mm), it is necessary to start working smaller drill diameter, after which it is changed to the appropriate one.

What drill drill tiles

The main requirement for drilling is its cutting part should be harder ceramics. This requirement corresponds to the following drills.

- With diamond spraying: they are relatively roads and therefore for one-time work are not the best choice.

- Specialized drills for glasses and tiles.

- With a winning tip: Such drills are cheap, they are recommended to acquire all homemade masters.

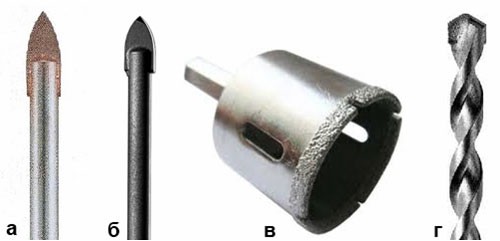

On the picture:

a - drill with diamond spraying; b - drill with a win-off "; B - crown with diamond spraying; G - drill on concrete and brick.

How to drill tile: work technology

- We celebrate the place of drilling hole with a marker.

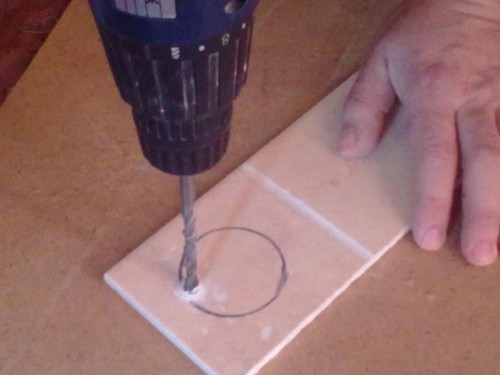

- We glue a segment of painting tape to the marked place.

- Greased the shank drill with solidol or any other thick lubricant, insert it into the drill cartridge (perforator).

- In the "Drilling without impact" mode, we begin to drill on low revs, gradually enhancing pressure on the tool. You can't "download" from side to the side. It is advisable to apply a special tripod.

- After the tile is drilled, it is recommended to replace the drill and continue drilling in the "with a blow" mode.

- After removing the drill, clean the hole with purging (using the vacuum cleaner).

Important: In order for the depth of the hole is not unnecessary, you need to apply the limiter or put a mark with a bold marker on the drill.

Big Diameter Hole Drilling

How to drill tile in the bathroom or kitchen to install a socket? It should be noted that this work is performed after electrical work, and therefore it will have to drill the tile not yet glued. Perform work in such a sequence.

- The marker should be noted the center of the hole after the exact definition of its place: it is necessary to predict the location of the outlet on the surface of the tile. It is important that it is closer to its center (especially if a small tile).

- The center of the opening is sealed with a piece of painting scotch.

- A crown with diamond spraying is installed in a drill.

- We establish a centering drill to the outlined place and begin drilling on low revs (without impact), gradually increasing them.

Important: The tile must lie on a flat, stable surface (for example - on the chipboard). The edge of the tile during drilling needs to be held in order to avoid turning the latter.

What to do if there are no crowns with abrasive spraying at the disposal? It can be replaced by its crown with carbide metal teeth. There is another way to get large holes: We note the place of drilling hole, and then use the following technology.

- According to the marked circle, a thin drill with a win-attack (or diamond spraying) drilled around the circle as many holes as possible (30-40 pieces).

- In one of the drilled holes, a string with an abrasive tungsten spraying is inserted and installed it in the holders of the jig.

- Make the circumference of the circumference, connecting the holes.

- Disassemble the jigsaw, remove the string.

- The edges of the opening are treated (if necessary) with a file.

For convenience drilling, you can use a special template.

Drilling tiles balleriny

In the event that the location of the communications is already known, the technological holes can be drilled by a special device - a ballerina. Outwardly, it resembles a cirkul: for installation in the center there is a special point, and the distance from it to the cutter determines the diameter of the opening.

A feature of the ballerina is the ability to adjust to obtain the desired diameter of the hole. But after drilling the edge, it is necessary to "refine". They will be even if the drill fix strictly perpendicular to the tile and during the drilling process the tool will not deviate.

Using the ballerina, drill holes for attaching a towel rail to install mixers and for internal sockets. Comparatively low cost and universality of the ballerina makes it convenient for domestic use.

How to drill a porcelain tile

To drill this solid ceramic material, use:

- diamond crowns with galvanic spraying (enough about 5 holes);

- drills sintered diamond ring.

The latter are used to process natural stones and concrete. Such drills serve for many years, but relatively roads.

The technology of drilling a porcelain stoneware is as follows.

- The processed tile is laid on a flat, not too solid surface.

- The tile is drilled without a blow on a small (medium) speed and exclusively on the front side to avoid the appearance of spoils of the species of the chip.

- The drill oriented strictly perpendicular to the tile.

- The cutting edge of the drill is cooled by water directly during operation. You can do this with a moistened sponge or bottle with holes in the lid.

- The hole can be deepened by 2/3 of the thickness of the tile, after which the excess fragment is dropped.

- Skin on the back of the process is not necessary: \u200b\u200bafter laying a porcelain stoneware they will not be noticeable.

In conclusion, on how to drill tile (video with explanations of a specialist).