Natural linen Olife: characteristics, composition, application paints and varnishes

In the modern market, all the variety of building materials can be divided into 2 large categories - natural and synthetic. The second is becoming more and more, and they are popular at the expense of less than high cost. At the same time, natural no less interesting to consumers, for example, linen olive are constantly in demand, the price of which is quite accessible even for the economical budget for construction.

Content

Natural Olife - composition and types

This material is based on natural flaxseed oil, which can be heat treatment at 300 ° C. In the finished form, this is a transparent liquid of a light yellow excavation of an oily character. The composition of linen oil includes only 2 components according to the GOST Regulations:

- flax oil - at least 97%;

- syccats - metal particles or carbon salts to accelerate the drying process, not more than 3.

Important! A manganese, cobalt and lead are most often used as sequivles for natural linen oil. Their use allows you to reduce the natural period of drying in 6-8 days a maximum of up to 1 day.

Depending on the applied production technology, there are 2 types of Oliflates:

- polymerized or standard - it is made by heat treatment without purge;

- oxidized or oxidized - when taking oils at high temperatures, purge technology is additionally used.

Important! According to the principle of a drying rate classification, natural linen olifa refers to drying solutions.

Natural linen Olife - specifications and advantages

Linen oil production is carried out according to GOST 7931-76 standards. According to these requirements, the technical characteristics of the finished substance correspond to such indicators:

- the percentage ratio of oil and sequivos - 97/3;

- natural pleasant fragrance;

- drying speed corresponds to 3 degrees - no more than 24 hours at air temperature in 20-22 ° C;

- shade on iodometric scale - 200;

- density - 0.93-0.95 g / m3;

- sucks - no more than 0.3;

- acid number - 5 (mg con);

- full transparency after settling for 1 full day;

- the inclusion of phosphorus-containing elements is not more than 0.015%.

Important! If you decide to buy natural linen Olif, note that packing can vary from 0.5 to 50 liters, as well as go on sale in barrels and drums weighing 20, 43 and 197 kg.

As for the advantages of this substance - they are as follows:

- almost 100% inconsistence of moisture;

- absolute mechanical stability;

- environmental purity, and as a result, harmlessness;

- a wide range of applications;

- savings on other consumables, for example, with finishing finish by painting.

Application of natural oils

Historically, "linen boiled oil" was used for impregnation and coating of all wood products and items to eliminate their rotting, strain during wetting, as well as to increase the resistance to parasites.

Today, the field of application of linen natural oils has significantly expanded - these are areas:

- domestic and external finishing works - staining of windows, floors, walls, doors;

- primer of metal and wood surfaces;

- inclusion in the component composition of thick oil paints, primers, putty;

- processing any items made of wood to extend the service life;

- restoration of furniture;

- pre-processing of surfaces and objects before painting to increase adhesive properties;

- protection against water permeability in the construction of small vessels - all metal and wooden surfaces are processed;

- breeding solutions of paint, putty, primer, to obtain the desired consistency;

- as an antiseptic in the construction of wooden log cabins;

- as a decorative finishing of floors, for example, parquet, and for further care of such coatings.

Processing Olphoy

The principle of this solution is as follows:

- when exposed to oxygen, heat and light outdoors, vegetable oils are polymerized - in linen oil, the content of acids that contribute to about 80%;

- some of the substances penetrate directly into the porous thickness of the material, and the rest creates a thin layer on the surface, as a result of which the efficiency of protection is achieved.

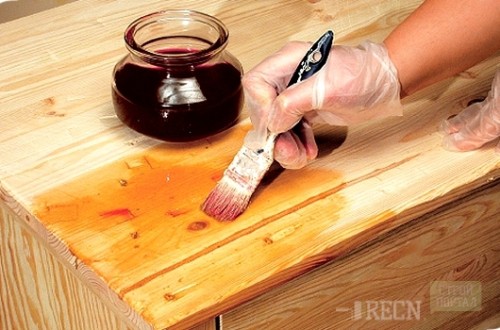

The rules of application of the Olifa are as follows:

- Before treating with a solution of any surface, clean it from all the garbage and dust. Wood materials are better polished.

- Make sure the processed material is dry.

- Application is carried out in several layers - depends on the requirements for attractiveness and the level of protection.

- Perform painting with a brush or roller - an indicative consumption will be from 50 to 100 grams per 1 m2.

- Upon completion of all the work, take away from the room and throw away all the rags impregnated with oil.

- Well ventilate the room, and if you allow the weather conditions, leave the windows open throughout the dyeing process.

- Getting started at the expiration of 1 day when the solution is completely polymerized.

Important! Before and after use, keep the natural linen olif in tightly closed containers in order to prevent drying it.

Conclusion

Natural flax oil-based olifa is a time-tested excellent alternative to many modern protective equipment. If you can not decide on the appropriate option for finishing and protecting wood, which would fully respond to your safety requirements, the yield is obvious. This is exactly Olife!