How to make a colon formwork with your own hands Construction

Columns in architecture are used to support slabs of overlapping and beams, for the design of the front entrances of cottages. With the help of columns, you can create rooms with a large area without partitions. The most durable are monolithic structures, for the construction of the column formwork. On how to choose the most appropriate formwork and how to perform its installation, goes on speech.

Content

About formwork for columns

Classify formworks for columns according to the method of application and by manufacturing material. According to the first character, the same and reusable, as well as non-removable. On the second feature of the formwork are divided into the following types.

Metal opal

- Made from metal. The advantage of them is the ease of installation and dismantling shields. Due to the accuracy of geometry, steel formwork columns forms a high-quality surface of the monolith.

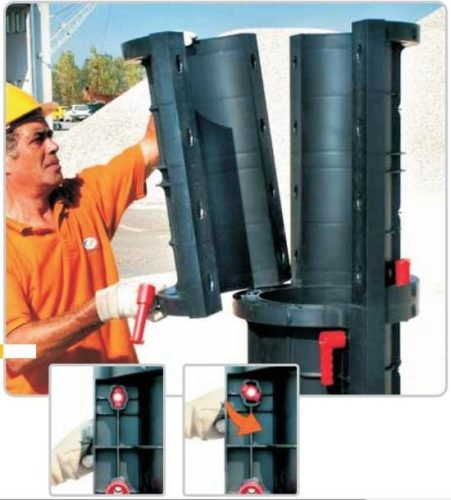

- Plastic formwork for columns: more often used for casting round structures. Such a formwork can be made of a plumbing pipe, selected in diameter.

- Wooden: Collected with the help of boards, plywood sheets and bars. Such a formwork is made independently and is suitable exclusively for casting rectangular columns. The disadvantage is the complexity of the assembly to obtain a design with proper geometry.

- Cardboard formwork for columns, which is disposable. It is a cylindrical form design of dense cardboard protected by special impregnations.

Installation of plastic formwork round column

Basic rules for mounting formwork columns

The wall formwork and columns are established in accordance with the general rules.

- The column, as well as the wall, has a small (compared to height) thickness. Such a feature must be considered when calculating loads on the formwork material.

- The pressure on the formwork in the upper part is significantly less than the pressure at the base of the column or wall.

- The big difference between height and width does not affect the stability of the mounted formwork. To prevent collapse, the design is strengthened by the backups.

- The formwork must be strong enough to withstand the weight of the concrete fill.

- The curvature of the design is invalid: the column with such a defect will be fragile.

- Strictly vertical should be a wall formwork and columns. The theory of calculations suggests that otherwise deforming forces arise that can destroy the architectural element.

Column Formwork Technology

Installation of wooden formwork rectangular column

Disposable formwork for the columns is going, most often, is assembled from wooden boards or plywood shields. This method allows to obtain an architectural element of a rectangular (square) form. To your attention a phased description of the process.

- The working drawing of the column with the size of the sizes is prepared.

- Formwork shields are collected from smooth boards. At the same time, their parties in contact with concrete must be academic and are stung.

- The ribs of wooden bars are fixed to the boards.

- Separate shields are connected using nails and self-tapping screws into parts for filling concrete.

- The reinforcement frame is manufactured. For this, steel bars with welding or knitting wire are connected to a rectangle shape.

- Wooden parts are connected around the reinforcement frame, a monolithic formwork of columns is formed. It is important that at the bottom of the construction the mount was reliably, since in this part the column a large load on the formwork.

Tip: In order for formwork to be easier to dismantle, its inner part is frown with a linoleum or polyethylene film.

In addition to boards and plywood for the formwork device, you can use sheets of extruded polystyrene foam or foam. Such a formwork may be non-removable. In the center of it is plastic pipe, which is poured with concrete. Before filling out the shape of the concrete, reinforcement performs and establish strengthening backups from different sides.

How to collect a formwork from cardboard

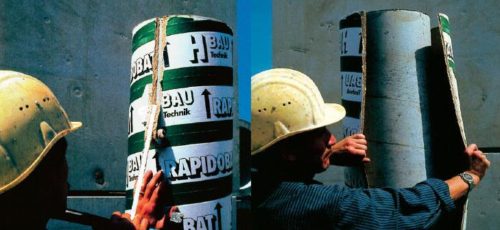

Construction of the column using cardboard formwork

If a formwork is needed round columns, a special cardboard is used. The advantages of such a material:

- relatively low cost;

- a light weight;

- ease of installation;

- the ability to create complex forms;

- good thermal insulation qualities (important in the cold season).

If there is no special cardboard, the column formwork can be carried out from ordinary cardboard. To do this, you must comply with the following conditions.

- The finely reinforcement grid of steel is collapsed into a roll (in one layer) in advance of the calculated diameter. The edges are fastened with wire.

- A roll is collapsed from the cardboard and stacked inside the grid so that it can crack and tightly lie on the grid.

- The finished formwork is installed in place with backups.

Note: In order to get a cardboard sheet of large sizes, it is necessary to connect the flashes using the needle the desired number of small sheets.

Dismantling cardboard formwork

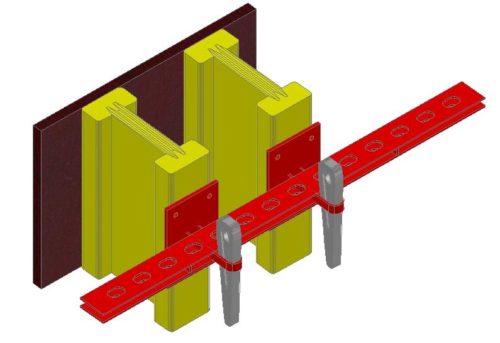

Beam-burglar formwork: design and installation

The formwork of this type is used to build walls and columns. The latter can be both rectangular sections and round. The advantage of such a formwork is accessibility for self-installation, without the use of special equipment and technology.

Phased description of the installation technique.

- The smooth place is selected for assembly work.

- On the planned distance (depends on the size of the column) on the flooring there are riglels.

- Wood beams are mounted perpendicular to the rigels. Fixing is performed using screeds.

- Shields made of thick plywood are screwed to beams with self-tapping screws.

- Wooden beams in the upper and lower part are strengthened by bars. This is necessary to prevent deformation under the influence of the mass of concrete.

- The collected shields are connected to each other with the screeds for which the holes should be provided. In order for ties in the corners reliably attracted shields to each other, wedge-shaped inserts are necessary.

Ballen formwork element

Note: All parts of the beamiboral, plastic, metal and wooden formwork can be used repeatedly. One-time is only a cardboard formwork.

In conclusion - video, clearly demonstrating how with the help of modern formwork systems, you can perform installation with your own hands, without the help of specialists.