How to make noise insulation walls Insulation,Walls

On the day off, it's nicely in the midwerome in bed longer, because you do not need to hurry anywhere. But it was not there - in the morning the crying of the child hears in the morning, the lessons of music are replaced at lunch, and in the evening the neighbors begin to find out the relationship. To get rid of sounds behind the wall, noise insulation of the walls will help.

Content

Do not hurry to ring up construction firms and artists on ads. If we think about everything and calculate, you can make noise insulation with your own hands.

Preparation of walls to work on noise insulation

Work is not very fast, so nothing can be missed. Do not sore purchasing drywall and other materials for noise insulation. The photo shows an irregular device of noise insulation. It may seemed to someone that wallpaper would serve as an additional layer of isolation. This is not true.

It is important not only to spend money insulation, but also know how to make noise insulation of the wall.

First of all, remove old wallpaper from the wall. View the wall. Fly loose plaster - possibly cracked under it. It is impossible to close the cracks with noise insulating materials - the results of your works will be impaired by half. Pay attention to the corners. If the walls in the corners do not converge more than 10 mm - close them with the mounting foam. Cracks on the wall need to be sewed and attached. Severe a crack - it means to increase it, projection and fill the plastering mixture.

Pay attention to sockets. In old panel houses a hole for a socket with you in common with neighbors. At best, it is filled with a thin layer of plaster. Remove the outlet. Increase the wire, taking into account the fact that the wall thickness will increase and the outlet will still have to be mounted again. Remove dust and dirt. The hole itself can be filled with circles cut from the ceiling tiles, better by mounting foam. Surplus are removed from above the plaster mixture. Wall abandoning will fully add its contribution to the quality of noise insulation of the wall, but the essential role will not play. The main thing is to close all cracks, sockets and corners.

When cracks remain on the wall, all the angles are with a neighboring wall, the ceiling and floor will be shuffled - you can start the choice of noise insulating materials.

What are the materials for the noise insulation of the walls

Materials are produced in two categories: sound insulation and noise absorbing. To get rid of sounds behind the wall use sound insulation materials. To get rid of yourself from the appearance of neighbors when you turn on the full power of the TV, use noise absorbing materials.

Fontar Panels (PhoneStar)

- This is a unique material that copes well with sound absorption and sound insulation. The panels consist of a cellulose frame made of cardboard and mineral fillers in the form of quartz sand. Have a small thickness - 12 mm are easily mounted. Mixed on noise insulating dowels in a checkerboard order. The seams are closed with an acoustic sealant. Cost - from 1200 rubles per square. What is a panel in the context, shown in the photo.

Ursa Geo Noisezashita

Good reviews have a material for noise insulation of the walls of the URSA GEO SHUOHO. Ursa is made from staple fiberglass. It has a small weight. Roll weight no more than 13 kg. It is used with noise insulation using a framework method.

Mineral Membranes Tecsound

TEXSA products (Spain). Made on the basis of aragonite - mineral substance. Have a high degree of density. Have excellent soundproof properties. It passes on plasterboard from the inside. Frames and frameless method are applied. As an independent material or in combination with mineral insulation, such as Urs, an avo.

Available in rolls 1, 22m width, 5 m long. Roll weight 7 kg. Roll price 800 rubles in roll 6, 1 m square.

Penophol

The best noise insulation of the walls is created with a combined method of using noise insulation materials. A good effect gives a layered material consisting of a solid layer - foil and soft - rubber or polyethylene.

An important value for the device noise insulation plays the price of the material. Compare the cost per square meter of noise insulation, which exists in your city and decide on the choice.

The total cost of noise insulation of the walls is also taken into account by the price of fasteners, profile, plasterboard. In the event that you use the frameless method of noise insulation, you need to calculate the cost of sound insulation materials and materials that will go to their fastening - dowel, fungi or mounting glue.

When noise insulation is performed by the framework method, add the cost of the frame of the aluminum profile or bar and drywall.

The costs of the device for noise insulation frame method are obtained above, but they justify themselves. The device noise insulation on the frame allows combining noise-proof materials, which affects the quality of noise insulation.

How to make noise insulation walls

Instruments

- level

- perforator or drill

- scrupovyurt

- construction knife

- hacksaw

- roulette

- hammer

- stapler

- capacity for kneading glue

- mixer, spatula

Noise insulation with framework

This method implies the walls of the walls with plasterboard on a frame with a laying of noise insulating materials between the wall and layer of drywall.

• The frame is mounted from a wooden bar or aluminum profile. It is impossible an aluminum profile to fix directly to the wall. Starting profile is attached to the ceiling and floor, the starting profiles are attached to the vertical frame racks. Pre-installation on the profile is glued with a special tape.

You can use the tape insulating dichunchshband from foamed polyethylene, or isolon. Ribbons are sold by rolls. Width 30, 50, 70 and 90 mm.

• After installing the frame, the insulation is mounted. The noise insulating material of URSA is cut by an ordinary building knife. To the wall, the material is glued with polyurethane glue, or glue for gluing URSA XPS plates.

• After installing the frame, the insulation is mounted. The noise insulating material of URSA is cut by an ordinary building knife. To the wall, the material is glued with polyurethane glue, or glue for gluing URSA XPS plates.

• Top is trimmed with plasterboard.

Combination of several sound insulation materials

When used for noise insulation, the membrane Texound material is glued along the inner side of the GLC.

When using foam, the material is glued onto the wall before starting the frame of the frame.

Frameless way

With a frameless method, the prepared wall is trimmed with soundproofing panels that have a surface for finishing finish. The panels are glued onto the wall or are attached to special dowels.

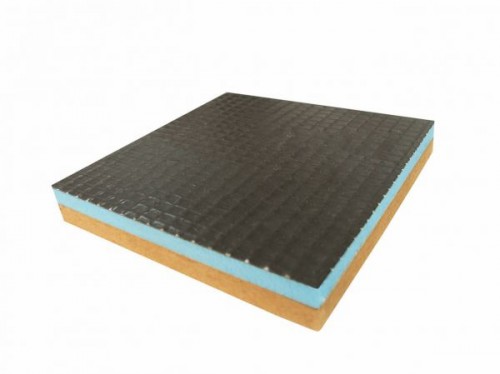

Sandwich panels for Soundproofing Comfort. Size 2500x600. Plates allow you to make high-quality noise insulation of the walls. The cost of the square meter of such a panel from 800 to 1500 rubles, depending on the thickness of the panel. The panel is made of three layers, it is a MDWF softboard, extruded polystyrene and an outer surface coated with a polymer compound with a reinforcing grid.

The panels are glued onto the wall on pelifix glue or with a glue plastering mixture. The surface of the panels is ready for further finishing finish - putty.

The panels are glued onto the wall on pelifix glue or with a glue plastering mixture. The surface of the panels is ready for further finishing finish - putty.

The illego-insulating panel system (SIPS) is performed by two-layer sandwich panels. The panels are - puzzle-coopweed gypsum fiber sheets coated with a layer of mineral sound-absorbing composition.

Panels are fastened with a frameless method. The thickness of the panels from 40 to 120 mm. The size of the working surface without grooves 1500x500 mm or 1200x600 mm. Panel weight from 18 to 21 kg. Cost of one panel from 900 to 1,300 rubles. On the panels there are mounting nodes through which the panel is attached to the wall with anchors.

Panels should not be mounted close to the corners of the walls, the floor and ceiling. In the corners, a special gasket of Vibrastek-M is laid. When mounting the sandwich panels do not appear slots due to the puzzle joint on the panels.

After the panels are fixed, the wall is trimmed with plasterboard.

How to make noise insulation with your own hands. Video.

Very good detailed lesson about the installation of the SIPS system.

Video. Noise insulation of walls with the use of URSA material.

Another very useful video.