How to choose a concrete mixer Instruments

Regardless of which materials a house is built, road or utility structures on the site, it is impossible to do without a concrete solution. It is this inexpensive and easy-to-manufacture mixture that allows you to securely fix all the design details and ensure its reliability. But all this, provided that the solution is really high-quality and properly cooked.

Content

If large volumes of the mixture are required, it is manually prepared by manually and long. More advantageous and correctly from a technical point of view, use specially intended for this technique - concrete mixers. From this article, you will learn how to choose a concrete mixer, what are the types of this technique, its differences, and you can also choose an optimal model for yourself based on the review of the most popular options.

What a concrete mixer choose - criteria, requirements

Depending on how much the solution is needed, as often to prepare it and in what conditions, the perfectly suitable model of the equipment is selected.

At the same time, such criteria are taken into account:

- The principle of action of the concrete mixer.

- The voltage of the power grid on the site and the power of the unit.

- Theoretical fuel consumption.

- Pears sizes for kneading.

- The permissible period of the cycle of continuous action.

- Concrete kneading time.

- The number of people involved in the process.

- Reliability of the manufacturer.

- Additional functionality affecting speed, quality and simplicity of component mixing procedure.

Important! It is extremely desirable to consider not one or more selective parameters, but a full range of requirements on points. Otherwise, the incorrectly chosen concrete mixer may result in braking of the development and generally provoke solid inconvenience for the person serving equipment.

Principle of action of a concrete mixer

To date, there are 2 basic and several types of special purpose concrete mixers.

Main species

- Concrete mixer forced. Distinctive features:

- the drum is fixed;

- the mixing of the mixture occurs by means of internal movable blades.

Important! Great for the manufacture of liquid, viscous, plastic mixtures of large volumes, and for the compositions with the inclusion of large-scale particles, it is not recommended.

- Concrete mixer gravitational. Unlike the previous type:

- rotation is carried out by the drum;

- the blades at this point remain in one place.

Important! Gravitational devices are more versatile, as it is used in the manufacture of rigid mixtures with the inclusion of large stony particles and in the production of lightweight watery concrete.

It is such equipment that it is better to purchase for private construction.

Modern types of special purpose

As additional varieties in a number of classification, these options can be distinguished:

- The turbulent concrete mixer is distinguished by an increased speed of mixing components without loss on quality indicators. Great for mixing foam concrete and other mixtures to quickly complete the construction of large scale.

- The planetary concrete mixer is a kind of compulsory cyclic type, but instead of the blades has a more complex element in the device (drive asterisk). Fully justifies its application in conditions of large construction sites due to the preparation of a mixture of high quality in abbreviated time, but requires special preventive maintenance. A significant disadvantage is a high energy or fuel consumption in the functioning process.

Mechanism device

Another important factor in relation to the principle of the concrete mixer is the device of the main working element. This feature distinguish concrete mixers:

- Reducer are more reliable, but respectively - expensive.

- Crown will cost cheaper, can break during operation, but in contrast to the gearbox units are subject to repair.

Important! There is a separate group of this equipment - concrete mixers, in which the mixing equipment is built into the transport facility. They are used mainly to work at remote areas of large scale buildings.

Power of concrete mixers

The power potential of concrete mixers has quite wide parameters - in the range of 150 W-3 kW. This indicator affects the possibilities of uninterrupted effects and the available amount of preparation of the mixture for 1 cycle.

To determine the appropriate parameters, consider such recommendations:

- up to 700 W - such concrete mixers are quite suitable for use in domestic conditions, that is, for private construction;

- from 1000 W - applicable in large-scale projects with large volumes of concrete mix, as they provide a sufficiently long cycle of continuous functioning.

Important! Choosing aggregates with a long continuous cycle, note that such equipment requires specific complex maintenance, respectively - a certain amount of technical knowledge and skills.

Parameters of mixing pear

At this point it is necessary to take into account several characteristics:

- Volume. From different manufacturers, it varies in the range of 50-1200 liters. Universal indicators for use in the context of private construction are aggregates designed for a mass of up to 150 liters. Please note that this is theoretical volume, and not an indicator of the output of the finished mixture, in reality it will be on average for a third less.

- Thickness and method of manufacturing walls. The thickness indicators vary from 2 to 4 mm. The walls of less thickness are usually made by one-piece, in thicker - the grip assembly is performed from individual elements by welding. Despite the presence of seams, more reliable, resistant to rupture and deformation, are the second-type concrete mixers.

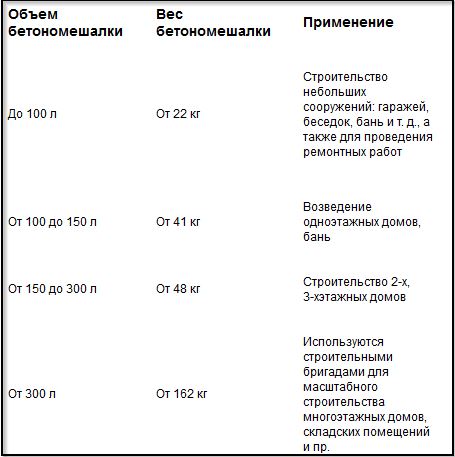

Important! Based on what type and scope of work you are planning to hold, make a suitable concrete mixer to the table below:

Additional functions

The convenience of operation, maintenance, as well as the level of safety in the process of preparing a concrete mix, largely depends on the presence of additional functions in the concrete mixer. These include:

- Method of loading and unloading components and finished mixtures. In cheaper models, the process is carried out manually, but for large volumes it is preferable to acquire a boot concrete mixer.

- The method of regulating the position of the pear. To make a mixture when the mixture is not poured, and in the finished form, the solution was conveniently unloaded into the desired container, it is desirable that the concrete mixer can be installed on the concrete mixer.

- Appointment and permissible conditions for work. These characteristics are meaningful in the case when frequent and regular use of concrete mixer is assumed, regardless of natural and seasonal conditions.

- Noise level. Additional noiseing elements will allow not only to make the process more quiet, but provide a pleasant atmosphere throughout the construction site.

- Waste volume. The volume of dust entered into the atmosphere is taken into account here. So that the process of cooking concrete was relatively safe, choose an aggregate with dust emission limiters.

Manufacturers and models of concrete mixers

Many companies are engaged in the production and sale of concrete mixers of different classes, destinations. Some of them showed themselves to a more profitable side, for which they received recognition from users. Basically, it concerns brands, such criteria are taken into account:

- reliability and durability of equipment;

- latitude of the range of model range;

- the duration of warranty obligations;

- availability - both with respect to the initial cost of the unit and if necessary to repair it.

The following trading stamps are considered the best today.

Guy Noel (France)

Supplied to the sale of optimal quality aggregates, mostly automated. The main advantage is often becoming their disadvantage, since it is the electronic control board most often fail, and quickly getting service and repair in our country is quite difficult due to the lack of a large number of service centers.

Altrad Spomasz JSC (Poland)

Expanded network offering excellent concrete mixers for various purposes. The species line allows you to satisfy all user requests. Including it includes the aggregates of a specific device designed to work in conditions of too high or low temperatures, with private natural precipitation or the absence of access to the power supply. Attracts attention and deserves confidence in Altrad Spomasz AO and for the reason that the experience of many engineers in its state is about half a century.

Limex (Croatia)

Concrete mixers of this brand have proven themselves as wear-resistant units operating with a small noise background. Products of this company, according to consumer reviews, quite rare fails. Fully justified with acceptable price reliability, even with a limited model range, does not reduce the popularity of Limex concrete mixers.

Bart Import Poland (Poland)

This Polish manufacturer competently approached the manufacture of its products. You can see concrete mixers with different capacity in the range of 120-460 liters, which are more compact, than other brands.

Special attention is also paid to the amplification of the coronary element, the engine, the engine, which causes their sufficient reliability and the possibility of long-term operation without additional funds for repairs.

It is the technical side that contributes not to such a significant disadvantage - the relatively low external attractiveness of the equipment.

Tsunami (China, Assembly Russia)

Under this brand is mainly produced by household concrete mixers of a small volume - up to 180 liters. The aggregates have proven themselves in operation in the conditions of our country in the direction of private construction.

Optimal indicators of reliability, functionality with a combination of maintainability, accessibility of service and low price. The perfect choice for many whose budget is limited to a small amount and is not expected frequent and long-term construction.

The RM125, 140, 160, 180 model range (nominal indicator corresponds to the volume of pear).

HERZ (Germany)

Herz is one of the leaders of concrete mixers. Justified German quality at quite an affordable price makes the equipment of this brand and in the conditions of our country.

The line has professional appointments, which initially correspond to high strength, reliability, functionality. Engineers in the development of aggregates are taken into account not only inquiries to the low consumption of diesel fuel, but also the technical conditions for access and transportation of concrete mixers at the unprepared track.

Lebedyan (Russia)

Lebedyan is one of the most popular domestic brands. The manufacture of concrete mixers is not the only direction of the company's activities, but meaningful branch.

The species line contains units for any user requirements - manual and easy to manage household aggregates and professional high-function systems.

When developing technical projects, all global developments are used in this direction, and their own ideas are being introduced to extend the service life, reliability, security and improvement of ease of operation of Lebedein's concrete mixers for users.

Affordable price and a widely developed service network in the CIS terms - an additional, but very important advantage over import brands.

Profmash (Russia)

Another domestic brand, whose products are characterized by a high quality class. The entire assembly cycle is carried out in Russia, due to which the price of concumbles is more than affordable.

Most often, a concrete mixer enthusiast is used by 130 liters, although other models also do not ignore. The technical compliance of the specified characteristics is confirmed by numerous tests at each stage of production, as well as at the end of the equipment assembly.

The advantageous advantage is the equipment of most models with a reinforced frame and transport wheels to move the equipment to a more convenient area of \u200b\u200bthe construction site to obtain a mixture.

Zitrek (Czech Republic)

Zitrek concrete mixers are advantageous for European equipment. Various models of this brand gained steady demand in our country due to a wide species series, including both household aggregates and professional industrial purposes.

Each plant is equipped with not only production lines, but also by special workshops for independent quality tests.

Concrete mixers of the following models are particularly popular for use in domestic conditions:

- B-1308-FK (0.8 kW, 690-600-660 mm, 52 kg, 130 l).

- B-1510-FK (0.8-1 kW, 700-700-700 mm, 56 kg, 150 l).

For more large-scale construction - B-1910-FK (1 kW, 800-800-800 mm, 64 kg, 190 l).

Kraton

The model range of this manufacturer is represented by 15 variations, among which there are brand concrete mixers from 46 to 300 liters. Depending on the specific execution, the equipment can operate from a network of 220 and 380 V, in some units not necessarily grounding.

Particular attention to the manufacturer has given noise insulation and strengthening the mixing pear, in particular, working units are closed with superproof casing. Due to this, the reliability of Cton concrete mixers increased. Accordingly, any consumer can with confidence choose a model suitable in all parameters without worrying about the need to repair.

Important! The above review is far from a complete list of popular brands. For example, concrete mixers PRORAB, ELITECH, scout use no less demand. What exactly to give preference - choose yourself, based on the suitable price range and other designated criteria.

Video

To more clearly imagine that and how it should be placed inside the concrete mixer, look at the video review below.

Conclusion

As you have already seen, not only from the technical side there are a lot of differences between concrete mixers. Different manufacturers each year find new solutions to improve their own products. Choose equipment only after clearly designate your goals. There will be a proven simpler design option or expensive with innovative functionality - to solve only you.