How to choose blocks for construction. Tips and recommendations Construction

More and more developers prefer to apply wall blocks in the construction of low-rise or industrial buildings. The big popularity of such products is due to the qualitative characteristics of the material used in the process of manufacturing products.

If you want to build a reliable home in a short time, you will be interested to learn what building blocks are.

Content

Types of wall blocks depending on the composition

The most popular wall blocks are made of heavy or lightweight concrete.

Produced products made of heavy concrete have high strength, waterproof, frost resistance.

The disadvantage of concrete is bad sound insulation and increased thermal conductivity. Walls of the house, which are elevated from heavy concrete require additional insulation. Most often, developers use concrete building blocks in the foundation arrangement.

When building a residential building, light concrete products are most applicable. These include wall blocks from cellular concrete, and these are foam blocks, gas blocks or clay products.

The structure of the cellular concrete consists of a hardened binder (cement, plaster) with uniformly distributed air cells. The porous structure of foam concrete is created by adding a foaming agent when mixing the mixture.

Gas-silicate or aerated concrete products are manufactured by introducing a gas formation. Having a loose structure, blocks from cellular concrete have a light weight, which greatly facilitates labor costs.

Wall blocks made of ceramzite concrete differ from cellular, the presence of inclusions from the clay, which is produced by firing clay by special technology. The density of the blocks from this material is higher than that of other types of light concrete. The strength of the material can compete with heavy concrete.

Any subspecies of light concrete has a number of advantages: the heat efficiency of the wall block, high frost resistance, light weight. The house built from such products has a good indoor microclimate, as the porous material of the walls allows you to create natural ventilation.

Purpose of wall blocks

Depending on the purpose of the product, the product is divided into structural, thermal insulation, partition, decorative.

1. Construction

Structural types of blocks are used to erect the bearing walls of the building.

If the house is erected using cellular concrete, then subsequently requires additional wall cladding, since the material porosity has high water absorption. Ceramzite concrete or aerated concrete building blocks do not have such a shortage. For example, building blocks ytong.of the aerated concrete, there have such a feature as the absorption of excessive humidity indoors or on the contrary, the return with its disadvantage.

2. Heat insulating

The thermal insulation species is used to further protect the building in a harsh climate.

Such type can include products made of cellular concrete, to which the requirements for strength and density are not presented, since the main task of thermal efficient building blocks to maintain a comfortable temperature indoor temperature.

3. Partition

Partitioning wall blocks are used to separate the common space on separate rooms or zones. Products for mounting partitions have a smaller width in contrast to structural. All positive characteristics of the material remain unchanged.

4. Decorative

If the facade of the building has an unsightly species, then decorative wall blocks that can be of different textures and shade are used.

This type of product is inherent not only all the quality characteristics of the material (strength, frost resistance waterproof), but the necessary decorative effect. Modern production manufactures blocks imitating natural stone or wood, which allows to diversify the facade of the building.

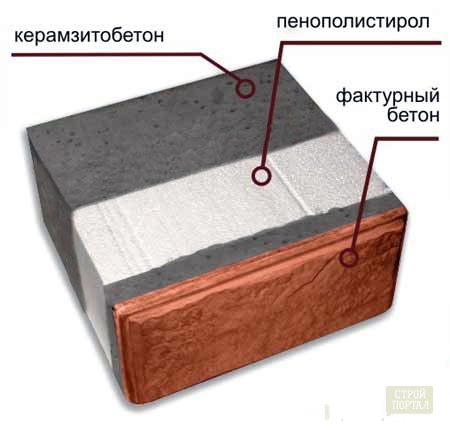

The new development in industrial production is a wall-wall thermostable, which combines in one product, all of the above properties and characteristics.  Buing a building from this type of material, you can get rid of additional heat-displacement measures and decorating walls.

Buing a building from this type of material, you can get rid of additional heat-displacement measures and decorating walls.

If you need to build a non-residential building in a short time, then you can use large wall blocks that are made of heavy concrete. To perform the installation of the walls, the lifting equipment will be required, since the lightest block weighs about 300 kg, and the largest reaches 2 tons.

What to draw when buying products

First of all, buy products from proven manufacturers. Serious companies are conducting full control over the production of products. Do not be lazy to read on the Internet reviews about the manufacturer.

High-quality building blocks have the same dimensions, with a flat surface. This can be checked by setting several products, close to each other. Orthodoxes on the surface of the products will result in the overrunning of the cement mortar, and also create cold bridges.

To assess the strength of the material, take a small piece in your hands and try to open it. If you managed to do it easily, it means that the manufacturer saved on the number of binder, violating the manufacturing technology.

Well storage and packaged goods will not lose their qualitative characteristics. Therefore, pay attention to the storage area of \u200b\u200bthe goods. The company, which is currentlying its reputation, stores blocks on wooden pallets, preventing a detrimental effect on the effects of the earth's surface.