How to choose a manual circular Instruments

Woodworking is one of the most popular and labor-intensive types of construction activities, and half of success depends on the quality of tools. In the early 20th century, manual circular saw was invented, which largely simplified the process of working with wood and increased productivity. Every year the design of the disk saws is improved, and choose the optimal option becomes more and more difficult. This article will help you understand the design features of the instrument and choose a manual circular for home and work.

Content

Common instrument characteristics

At the very beginning, the console woodworking machine was invented, thanks for which he follows the brilliant Rammond of the Devolt. The principle of operation of this machine was mastered, adopted and began to develop on other manufacturers. As a result, some time later, Mitchel and Salivan collected a manual circular saw. Later, A. Styl got a patent for the integrated drive of the cutting disk, and Emmons - on the side. In the end, the first "full-fledged" manual circular was represented by the German company AEG, which launched a line of power tools with a power supply from 220 V.

Modern circular is different from the first developments primarily with the widest functional, which allows you to declare with confidence that there is nothing more to add here. Therefore, new models that appear every year on the market differ only to the improvement of existing options - more compact dimensions without loss of power, more acute and durable blades, etc.

The disk saw design is quite complex, since this tool simultaneously meets the high requirements for settings and accuracy, and also provides fast, efficient and safe operation. Due to the complexity of the device, repairing the saw with their own hands without professional skills is urgently not recommended. Circular or "Barquet" are used to obtain longitudinal and transverse cuts on wood and any of its derivatives (laminate, parquet, plywood, chipboard, etc.). It is worth noting that to work with laminate, sandwich panels, plexiglass and plastic materials, you must use special discs and set the appropriate job settings. Powerful multifunctional devices are able to cope even with slate. Restrictions exist existed by the nature of the cutting - the circular can "go" only in a straight line.

Important: Circular saw is designed for working with relatively soft materials and cannot be used to treat brick, concrete or other hard materials. However, there are exceptions in the form of improved models of type Makita 4101RH equipped with a cooling water supply system and a high-strength diamond disk.

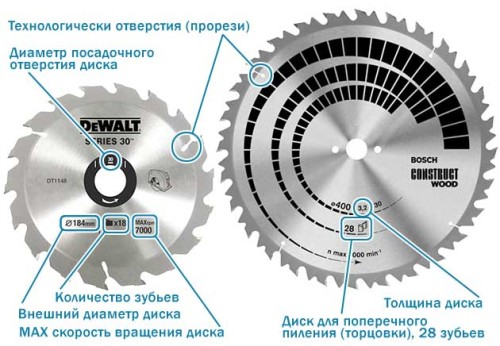

How to choose discs for circular

So, we smoothly switched from the design features of the circular to the varieties of disks used to work. The final result, the speed and materials with which the Master will be able to work are depends on. First of all, you should know that the discs can be with or without carbide attacks. The latter use when working with soft wood varieties to obtain neat smooth propyl. With solid rocks and all the more metal, the disk without attack does not compact, and if a nail or thick bracket is accidentally falling in the tree, the disk will lose the "teeth" and it will have to just throw it out - repair and sharpened is useless.

For this reason, many masters prefer to be reinsured and use discs with carbide attacks. They are not terrible random nails and other obstacles, however, the result is more coarse and not so smooth, as in the case of a "delicate" disk.

There are not only disks themselves, but also forms of teeth on them: active and passive. In the first case, it means that the sharpening angle of the teeth is positive, that is, the tooth is bent along the rotation of the disk, in the second - negative, that is, against the stroke. What does it affect? If you work as an active disk, you can not be afraid of nails in the tree and cope with plexiglas or solid plastic. If there is a passive disk with a negative tilt angle, the tool will cope with particularly solid materials: copper, tin, etc. In principle, such a disk can work with wood, but it gives the too "shaggy" cut, because the teeth do not cut, and we speak the material. Therefore, before choosing this device for manual circular, decide with what materials you will work.

Types of circulars

All circular saws are designed for rapid flowing and creating a smooth cut. This is an indispensable tool for any builder or dacket, but to choose the optimal option, you should learn a bit of theory. So, there are several varieties of hand circulars, characterized by the principle of exposure to the material.

Submersible circular

One of the varieties of disk hand saws used to create gutters, removal of grooves, cracks, etc. With it, it is very easy to make a hole in the tabletop for the sink - the design of the tool allows you to work not only with the edge of the material, but also in any other place.

The submersible circular saw is indispensable when repairing the floor and roofing works. To get a smooth cut without chipping, the work of a manual circular should be made in two stages: first the blade goes to a small depth, and with the second occasion - completely squeezes the material. The tool allows you to do both perpendicular cuts and at any given angle.

One of the most popular Makita SP6000SET models is notable for the fact that it does not have a lower casing, and the cutting element is located above the support plate. Thus, when the circle is turned on, the material is lowered and cuts. The cutting depth can be monitored and varied at its discretion with an accuracy of a millimeter.

Rechargeable Circular

Rechargeable disk saws and other autonomous tools are particularly demanding because they do not need nutrition from the network, and therefore mobile and convenient to use. Especially useful such a tool will be for high-rise works, which is not possible to supply food and have to "fight" with ubiquitous wires and extension cords.

The main problem of all rechargeable saws until recently was the lack of battery capacity, which was not enough for continuous continuous operation of a powerful tool. In low-cost models, this situation has not changed, so you need to look for a good accumulatory circular among professional lines of high price categories. Specialists recommend immediately choosing a saw, equipped with two batteries: one in work, the other - on charging. One of these models is Makita HS300DWE. To fully charge batteries, just 30 minutes just 30 minutes, which provides non-stop operation and high labor productivity. If we consider other technical parameters, such as power and speed, it is worth paying attention to the GKS 36V-Li saving of the German Bosch manufacturer - it makes a sharp up to 54 mm and is very convenient at work.

Circular metal

Most circulars are designed to work with wood, but you already know that if you put a special disk with inverse teeth on the tool, then some types of metal can be cut. However, there is a separate class of circulars created specifically for metal cutting. In essence, these are advanced woodworking tools that work well with metal and excellent - with wood and other less solid materials.

Usually on tools for working with metal, such as Bulgarian or angular grinding, it is worth an abrasive circle. In the circular, the gearbox from particularly durable steel is used, which gives a lot of advantages compared to other devices. So, the productivity of labor increases several times, because the saw is faster and more convenient. As a result, labor intensity is reduced, because the circular has a support sole that takes the load. The noise of saw is much less than the same Bulgarian, while it does not heat the metal and does not allow sparks. Working with this tool is much safer than with an angular grinder, since the cutting element is almost completely closed by a protective casing.

Cutting discs for metal circulars are distinguished by a high resource, and therefore they are enough for a long time. For this reason, the cost of cutting metal products is practically kopeck, and the quality is at the height - the slice is flat and without burrs.

In the West, almost all professional builders and domestic masters are used in the Western metal, but they appeared in the domestic market relatively recently. Nevertheless, Russian specialists have already managed to appreciate the comfort of working with such a powerful device. One of the most remarkable models of Evolution 230 Extreme is capable of gently and quickly cutting sheet steel up to 12 mm thick or steel pipe with walls with a thickness of up to 4 mm. Accordingly, the saw with the wood and polymer materials, the saw copes just joking.

How to choose a circular?

Of all the above, it becomes clear that the number of sentences on the market is very large, and you need to know what to pay attention to when choosing to find "your" tool. So, all manual circular chairs are distinguished by power consumed, productivity and depth of cutting.

Depth of sawing

The depth of sawing can be from 40 to 46 mm, from 50 to 55 mm and from 65 to 70 mm. The most popular is the second option, because it is precisely such a depth often needed for household construction and various carpentry. There is also a professional tool with a depth of cut to 140 mm, but it is used to work with thick logs or bars in production. For domestic use saw capable of immersed by 70 mm more than enough.

The greater the depth of cut, the more with thicker blanks you can work. This parameter also depends on the size of the most cutting element. The maximum disk diameter for household and semi-professional circular can be 190 mm. In many autonomous models there is a regulator of the inclination, which makes it possible to do a cut at an angle with respect to the base to 50 °, but the depth of such a cut is limited - a maximum of 49 mm.

In most cases, the indicator of the depth of the propyl point is indicated on the package or in the technical documentation, but some manufacturers do not consider it necessary to focus on this. If you have not found this data yourself, inquire yourself from the seller-consultant.

Rotation frequency

However, the most important quality indicator is the frequency of rotation of the cutting element. When choosing it, it is necessary to pay attention to the first place, since it is precisely from the number of revolutions to the instrument's performance. What it is more, the more solid materials you can work. It will also be useful to inform about the additional function of smooth descent - with its help you can avoid sharp jumps in the engine and extend the "life" of the instrument several times. In addition, the smooth descent protects the engine from overload and ensures the fastening of the spindle.

Circular saw is considered a relatively safe construction tool, but since there is automation and cutting element, a certain risk is still present. Carefully inspect the saw for protective casing and rubberized linings.

The rotational speed indicator also indicates the purity of the cutting surface - the faster the disk is spinning, the cleaner and smaller cut. The minimum speed of rotation is 1400 rpm, the maximum - 5000 rpm. Judging by the reviews about manual circular, it is very convenient if you can adjust this indicator and adjust it to work with various materials. However, it is not necessary to think that the rotational speed is directly dependent on the power, and vice versa. Among the most popular models with the highest turnover, you can select AEG BKS 18 LI-302C, Makita DHS 710 RM2J and Bosch GKS 36 V-U Professional.

Battery capacity

So, if you need a circular, operating autonomously, the first thing to pay attention to is the battery capacity. With the advent of lithium batteries, which came to replace Nickel-Kadmiev, the range of autonomous electrical instruments has expanded significantly. In the case of circular saws, the maximum duration of continuous operation on one battery is 25-30 minutes. If you have only one battery, you have to take a break and wait until it charges. That is why it is more rational to buy models, equipped at once with two batteries with a large capacity.

In low-cost autonomous circulars, the battery capacity rarely exceeds 3 A-h, which allows you to work no longer than 15 minutes. This is enough for one-time manipulations, but not for serious repair or construction work. If you need a device with high performance, choose models with two batteries of 4 A-h, the total voltage of which is 36 V. Then you do not have to be distracted too often for charging.

Useful advice: Lithium batteries are good in that you do not need to wait for their full discharge to charge. If there is no need to work in non-stop mode, during breaks, put a recharging tool for a few minutes. Then you can work for several hours without being distracted by a full battery charging course. For such work, the Makita DHS 710 RM2J model is well suited. Also recently, more "live" models with 5.2 A-h batteries, for example, Festool TSC 55ReB and Metabo KSA 18 LTX appeared on the market.

From the battery voltage directly depends on the power characteristics of the instrument, therefore, for regular use, it is better not to choose a model with a total battery voltage less than 18 V. Of course, it is significantly reflected in the cost. Thus, energy-intensive models with a large number of revolutions and deep cuts are not less than 35-40 thousand rubles, but it is not at all necessary for household use that all parameters are maximum. If you need a good tool for a home or workshop, you can stay on the device with one battery and not too high rotational speed, the cost of which is about 20 thousand rubles.

The manufacturers of the power tool are very much, but special trust uses AEG, Makita, Bosch. From domestic producers, you can allocate the Moscow Radio Engineering Plant, which produces circular at affordable prices, not inferior in quality to foreign analogues. The name and reputation play your role when choosing, but repel all the most reasonably not even from the cost, but on the technical characteristics of the tool. It is also important that specifically you would be comfortable to keep it, so do not hesitate to take a circular in your hands. What it will be easier, the longer you can work with it. For example, saws from Makita and Bosch weigh about 3.5 kg, Dewalt tools are a little harder - about 4 kg.

In addition to the saw itself, you may need a table for manual circular. It can be ordered, but, as a rule, people finding themselves with a disk saw, know the felt in a joinery, and therefore they can make the table for hand circular with their own hands. We hope this article will help you make the right choice. Finally, we suggest to see a useful video review.