Sharpening chain for chainsaws with their own hands Instruments

The performance of any cutting tool depends on how well it is sharpened. In the case of a chainsaw, the situation is a bit different - the plug-in tooth chains not only reduce productivity, but also make work more severe, long and inconvenient. Many professionals agree that a qualitatively sharpened chain is much more important than the engine power, and today you will learn how the sharpening chain is carried out for chainsaws with your own hands.

Content

Technical moments

By and large, the sharpening chain for chainsaws is practically no different from working with other tools for cutting wood. However, in order to get a high-quality result and make the blade correctly, it is necessary to know its configuration. Teeth chainsaws have a complex form, and therefore injecting users there are difficulties with their sharpening.

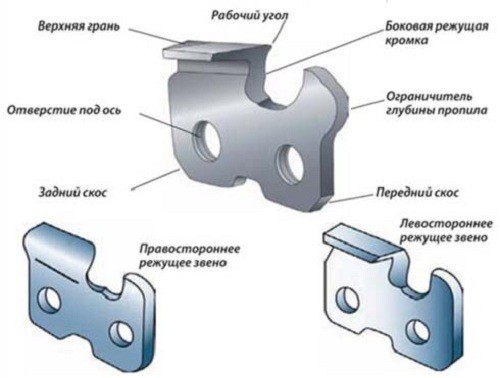

Teeth device

Teeth chainsaws are not like ordinary blades - everyone has two edges, bevelled at a certain angle, which makes it easy to cut the wood, but to gear it as a plane. In this case, depending on the height on which the limiter is set, you can control the thickness of the chips. With intensive work, the chain is blinking quickly, so it is often necessary to sharpen it several times a day, even if you work with soft wood, not to mention solid rocks. In addition, if I accidentally hurt the saw with the palate, the teeth are instantly blocked, and further work will become impossible.

Specialists recommend not to wait for the complete blurring of teeth, and to sharpen the chain after each use - for prophylaxis. The fact is that with a regular corrective assessment you remove less metal with teeth than with a solid sharpening stupid saw, therefore, you extend the life of the tool. To achieve maximum cutting indicators, teeth blades should be sharpened under a certain bias. The part of the tooth, leaving back, is responsible for the formation of the rear angle of the upper blade, which is included in the wood.

The front angle of the cutting element can be 60 ° -85 °, depending on which saw you use and what work are you planning. The rear angle can be 50-60 °. It is difficult to measure it difficult, and this parameter more depends on the observance of all technical values. You can change the angle if necessary, the main thing is to remember the simple rule: the more the indicator, the easier it is to work with soft wood. If you have to deal with frozen material or solid rocks, the corner reduction will reduce vibration.

Useful advice: Try not to make an angle sharper 25 ° and dumber 35 °. The exceptions are special chains for longitudinal saws with an angle of 10 °.

Each link is equipped with a cutting stop limiter. The position of the limiter determines how deep the upper blade will be included in the material, respectively, the very effective efficiency itself. Stop the parameters of the limiter in accordance with the chain step. Most often this value is 0.5-0.8 mm. If it is higher, the saw will have a strong return, too big capture and tangible vibration. If below - fees performance. Since the distance of the limiter becomes less after each procedure (the top edge of the tooth is stepping), it is also necessary to direct it from time to time (after every 5-7 sharpening sessions).

When should I sharpen a saw?

So, how to understand that the time has come to sharpen the saw? First of all, you will notice that the speed of the passage has decreased significantly, the tool began to vibrate stronger, and even it became harder to work. The speed of the chain is largely affected by the intensity of work - the more often the saw, the more often it must be sharpened. The second fundamental factor is the materials that you solve. If it is a soft wood, the teeth will be blurtled slowly, but if there was a contact with the soil or solid elements, for example, with bitch, the saw quickly fails.

How to understand that I saw fucked:

- Pulling and sagging chains.

- The saw blade works inaccurately and stuck in the material.

- Slowing the sawing process.

- Strong tool vibration.

- Changing the appearance of sawdust - their edges become torn, sharp, size decreases. Well-fulfilled saw gives a rectangular neat chip of the same sizes and shapes.

Not only uncomfortable and slowly work, it burns much more fuel. In addition, due to high vibration, the tire and leading asterisk are rapidly destroyed. In fact, each working tool node wear out, and several sessions of the work of a stupid saw can lead to serious breakdowns.

Sharpening sawmills

You can find several adjustable chainsaws on sale. One of the most popular is a special set consisting of several files, templates and a small hook. The round file is installed in the holder, the flat is necessary for processing the depth limiter, and the hook cleans the chain from the stuck pieces of wood. On the holder you can see several lines for the correct positioning of the tool in relation to the chain. The holder put on the tooth, which must be sharpened, in accordance with these landmarks. The plate at this time will become on the upper edge of the tooth and the limiter, so that the file will be located down from the cutting edge. You can buy a set of films for sharpening in almost any specialized store tool store.

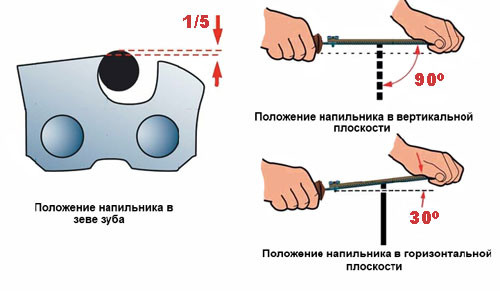

The holder allows you to clearly control the height of the edge of the file to the tooth. It is chosen depending on the chain step. If it is correctly chosen to the diameter of the file, its tip will perform over the edge of the tooth on 1/5 of the diameter. Sets for sharpening chainsaws in this regard are very convenient, since all the tools are already selected there in size.

Sharpening saw file

Before proceeding to work, carefully fix the bus using a clamp. Install it on the edge of the working surface (it can be a table or workbench). Using a chain chains for sharpening a chain chain, you will save on renting or acquiring equipment. This is a budget option that still has its drawbacks. The most obvious is the time consuming - in order to put all the teeth of patience and strength, and this will also take a lot of time. In addition, the sharpening spoils the tool itself, so in this case it can be considered a disposable.

To obtain a qualitative result, it is necessary to properly select a chain sharpening tool, or rather its diameter. If you work with a chain of 1.3 mm, the file diameter should be 4 mm. For chains by 1.6 mm, a round file is 5.2 mm. Flat are used to remove the limiters in the cutting elements.

Below on video - sharpening chain chainsaws County:

During manual chain sharpening, chainsaw is important to save the same angle. To do this, on each of them there is notice indicating the maximum allowable level.

In addition, you will use another tool - leaf or template for sharpening chainsaw chains. Secure it on the bus, select the desired angle and secure it. After that, you will only stay a few times with a file in the direction of yourself.

Useful advice: Make 2-3 light movements in the template. Do not apply excessive effort - lead a hand measured, scrolling the file, in order to prevent one-sided erasing. Experienced masters advise first to sharpen all the teeth, "looking" in one direction, and then change the position of the template and sharpen opposite elements.

To sharpen each tooth, make the same number of movements and observe equal pressure on the file. So all the teeth resulting in the same length. Otherwise, the chain will walk unevenly and can even crack. This is one of the most serious dangers that prompted many inexperienced users to donate saws into services. Chain sharpening price for chainsaws is lower than the cost of a new chain, plus you get a guarantee from the wizard.

If you draw the chain of 4 or 5 times, then the teeth have become shorter and you need to not forget to apply the depth limiter. Take a template on it so that the limiter gets into a slot, then descend the protruding tip flat file.

Sharpening saw with manual machine

Unfortunately, the method described above is not suitable for all chainsaw chains. So, if the cutting edge has lost its original shape, the file will have to work for too long and certain skills will be required. For such cases, it is recommended to use the machine. It can be manual or electric, with a stone or circles for sharpening chainsaw chains.

How to work with a machine:

- Unscrew the chain clamp regulating screw.

- Install the chain by sending it to the links towards the sharpening circles.

- Add the desired sharpening angle.

- Next, you can process the teeth in series, each time I rearrange the polarity, or first sharpen through one, then change the polarity and treat the teeth of another direction.

- If you work on a hand machine, determine the degree of sharpening, focusing on the most dull tooth. It is not recommended to negotiate the chain too deep to not reduce the strength of the links too much.

Useful advice: After sharpening, blow the chain with compressed air, after which it is for several hours to lower it into clean machine oil.

The advantage of this method is the maximum accuracy that it is impossible to reach with files or a grinder, but for this you will need to buy the machine itself.

Sharpening saw Bulgarian

Most experts believe that it is a "barbaric" method of sharpening, which can seriously harm chainsaw, but the practice of using the Bulgarian still exists, therefore it is impossible not to mention it. The only farewell - if you are going to sharpen the chain for the first time in my life, better use a file or machine to understand the essence of the process and "fill the hand." In terms of competent handling of the grinder, you will be able to high-quality teeth and do not spoil the chain.

Features of the proper sharpening chain chainsaw with a grinder:

- The chain can be sharpened without removing the chainsaws.

- To work it is recommended to use a 2.5 mm disc drive. Better, if it is already "started", that is, with rounded edges.

- The complexity is that the sharpening angle here can only be selected visually, for which at least a little experience is required.

- Between the bottom side of the tire and chains, install a wooden wedge.

This is one of the cheapest, unearmable and fast sharpening methods, but it is suitable for experienced users who speak the grinder well.

On the video about sharpening chainsaw chains, this method is clearly demonstrated:

Regardless of the selected technology, you should not forget about safety technician, even if you work with conventional files. Watch out for the evenness of the chain sharpening and in the case of which "customize" all the teeth under the shortest. Otherwise, the uneven stroke of the chain can lead to its cliff and injury.