Installation of chimney with your own hands Construction

Installation of chimney is an extremely responsible procedure. After all, the slightest inconsistency of the requirements and chimney will work incorrectly, it will begin to condensate moisture, or even cease to bring the smoke to the street. Installing yourself quite simply, but simple instructions are required.

Content

Types of chimney

Chimneys are the following types:

- metal,

- sandwich Pipes,

- cast-iron

- stainless

- ceramic.

The choice of whether or other chimney directly depends on the operational features. So, metal or cast iron chimneys are used for baths or boilers. This is the cheapest option, but it has a number of shortcomings. First, it is impossible to completely get rid of smoke leakage, secondly, use in external structures is not recommended. The impact of moisture negatively affects the metal, as a result, the chimney begins to rust.

Sandwich pipes are a design that consists of two pipes separated by an insulator. One of the pipes takes the smoke, the second is decorative. The insulator prevents the heating of the decorative tube and protects against fire.

Installation of the stainless pipe is recommended to be carried out where there is no possibility to carry out the inner gasket of the chimney. Stainless steel is the easiest material, so it is easily fixed even with a minor number of fasteners. In addition, it is enough to work with it. The stainless steel is easily cut as a grinder and metal scissors.

Ceramic chimneys today are practically not applied. This is due to the fact that the construction of such a design is carried out simultaneously with the construction of the whole house. Create a ceramic chimney can also be in the finished home, but for this you will have to disassemble a significant part of the inter-storey floors and roofs. This is the most expensive and practical option of the chimney mounting.

To install, you need approximately the same tool for mounting pipes:

- trowel,

- chisel,

- putty knife,

- bulgarian,

- drill with a set of stone checked,

- lobzik,

- screwdriver with a set of nozzles "Hexagon",

- crosshead screwdriver,

- small hammer

- pliers,

- metal hacksaw,

- gloves.

If something is missing from the list, then you need to buy or rent a missing tool.

Recommendations for the installation of chimney

Chimneys are carried out either indoors or outside. There are fundamental moments, by virtue of which it is more expedient to choose one or another option.

Internal chimneys are used for fireplaces or heating boilers. As a rule, they are mounted in the wall or decorated. Internal chimneys make it possible to avoid condensate formation. In addition, they are not exposed to dampness and wind.

But it should be remembered that smoke has a sufficiently high temperature. This leads to the fact that the pipes are very hot and contribute to the drying of the surrounding surfaces. One of the possible consequences is ignition. Therefore, internal chimneys are not recommended for powerful heating boilers.

External chimneys are designed for industrial heaters that are heated area over 500 square meters. They are used in the event that the inner chimney is too difficult. For example, if the structure has several floors with concrete overlap, much easier will make one hole outward than punching the concrete.

Installation of metal and cast iron chimneys

Installation of a metal chimney is one of the cheapest ways to conduct an internal chimney. The process is divided into the following steps:

- Pipe channel preparation.

- Install the chimney.

- Insulation.

Before mounting chimney, the smooth channel is made, which will pass the pipe. The hole must be 1.5 times greater than the diameter of the pipe.

The chimney itself consists of:

- pipes

- adapters,

- capacitor

- podle.

Some chimns provide a special branch to increase traction - Sewber.

Installation steps:

- Pipe fitting.

- Installation in the pipe canal.

- Constressor connection.

- Connect to heating device.

- Installing the headband.

Each and a half meters, the chimney pipe is attached to the wall with a special clamp. The total height of the chimney over the skate of the house is calculated by the formula in meters : Your height from the beginning of the chimney pipe and to the skate * 0.5 / 3.

Installation of steel pipes involves even high-quality insulation between chimney and inter-storey overlaps. For these purposes, it is best to use clay. Also, the refractory mounting foam is suitable.

Pipe installation technology includes decoring this item. For this, refractory materials are applied.

Installation of cast iron pipes is carried out by the same scheme as metal. But the cast iron is much harder, therefore there are some technological differences:

- mounts are performed every 50 cm,

- the hole under the pipe channel should be 2 diameters of the chimney.

Cast iron is more durable, but it's hard to work with it. This is especially true of cutting. Without the presence of a high-quality tool, it makes no sense to install a cast-iron chimney.

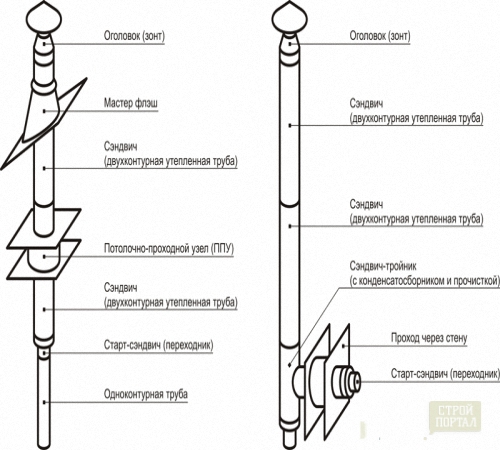

Installation of sandwich chimneys

This technology has replaced with standard metal pipes. Sandwiches allow to minimize the heating of the chimney, so the diameter of the pipe channel should only be slightly larger than the diameter of the pipe.

The technology of chimney from sandwich tube has several differences from metal analogues. Pipes from cast iron and iron are included in the grooves and under their own weight prevent the smoke to the outside. The sandwiches use gluing. Connecting two pieces of pipes, construction glue is applied to the inner edge. Sandwiches are securely fixed and give complete smoke insulation. Glue, in this case, also serves as a sealant.

The only drawback of sandwich pipes is condensate. By virtue of their physical properties, they critically react to temperature differences. Therefore, their applications are not recommended for external work. The service life is from 50 to 70 years, depending on the manufacturer.

Installation of external chimney

By the ratio of price-quality, the most acceptable option for mounting the chimneys on the street will be stainless steel. It is easy, affordable and perfectly processing even without power tools.

Installation of the chimney pipe looks like this:

- Punch in the wall hole at an altitude of at least 50 cm from the boiler.

- Install on the wall of the house mounting for a pipe at a distance of at least 1 meter from each other.

- Connect the inner chimney to the boiler.

- Take the pipe through the corner to the street.

- Install the capacitor.

- Secure the pipe.

- Install the roof over chimney.