Installation of the gas boiler with your own hands - instructions Climate,Useful advice

Autonomous gas heating is a common method of housing heating, both among homeowners and owners of apartments. Today it is the only way to achieve a comfortable temperature in residential space, besides at lower prices than with central heating. But, despite the efficiency of work, the installation of the gas boiler is a rather trouble-free process that requires skills and skills.

Content

Features of the installation process

Heating housing gas recently becomes more and more popular. This trend is due to the following factors:

- gas heating is a fairly convenient option to use;

- the structure of the structure does not require substantial professional intervention, due to which it can even establish a newcomer;

- equipment does not require additional costs when used.

Installation of the boiler provides the following steps:

- Direct installation of the gas unit.

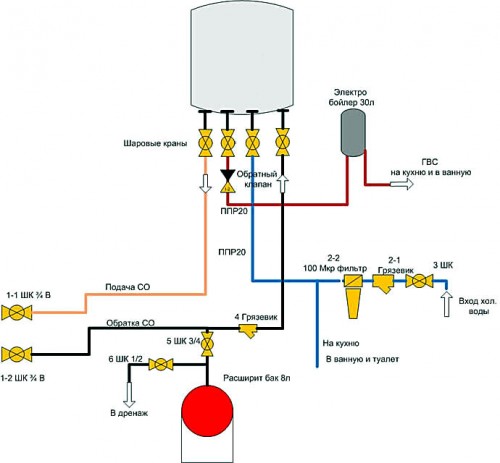

- Connect the heating circuit.

- Connection with heating system.

- Accession to the gas pipeline.

Important! The process and installation scheme of the gas boiler requires certain knowledge and skills. Otherwise, the best output will entrust this process by a specialist who can guarantee security during the operation of the device.

Choosing equipment

When choosing a gas boiler should pay attention to the following points.

- The housing unit must not have any defects.

- Be sure to check the completeness of the equipment - the availability of instructions, fasteners and components.

- You should also pay attention to the material from which made the pot, because it affects its service life. Gas aggregates made of iron and steel. In similar performance capacity and the volume of steel boiler it has a lower weight. However, the service life of steel boiler is between 10 and 15 years, and cast iron - up to 30 years of service.

- In addition the unit selection should take into account the possibility of falling pressure forces in gas networks. This phenomenon provokes "settling" of the flame in the burner of the heating equipment. In this regard, give preference to units with fan burners, and not atmospheric.

- For optimum performance, the boiler should consider setting power. To avoid problems in operation of the unit it is recommended to use a surge protector or a stabilizer, a normalizing voltage. Today, the market can find a boiler that turns off automatically in case of over-voltage standards, while maintaining the technical parameters of the equipment. With the resumption of normal boiler supply restores normal operation.

Important! If you intend to mount the boiler yourself, you should contact the appropriate authorities in order to obtain permits. The specialists will develop the project of gasification of housing, which will be listed characteristics of the required equipment. After receiving such a project, you can proceed to the selection, purchase and subsequent installation of the device.

Site Requirements boiler installation

Consider what options should be considered before you begin the process of installing a gas boiler in your home:

- The first thing to consider - this is footage of the room. It should not be less than 4m 2. It is desirable to allocate to the installation of a separate gas boiler room. This is due to the fact that the heating equipment is more power in comparison with analogues.

- In order to protect the walls of the room where the unit is installed, it is recommended to cover the refractory material.

- In the case of wall-mounted apparatus, the installation area must be located at least 80 cm from the floor and 50 cm from the walls. Also in the room where you plan to install the boiler is necessary to organize the chimney.

- The window should be provided in the fiber opening, while the door width should be at least 80 cm.

- If there is no possibility to equip separate ventilation of the unit, you can buy equipment with an existing turbine. The essence of the removal of combustion products in such boilers is that the outflow occurs through the inner tube. And the external tube at this time provides air flow.

- According to the rules for installing a gas boiler, the unit is unacceptable to install in the bathroom or bathroom. If the kitchen is selected as a place for mounting, then give preference to the products with a built-in gas analyzer, which in case of an emergency will provide an opportunity to establish a problem in time.

- The output of the gas feed should be vertically and climbed over the ridge of the roof at least 1 m.

Installation of an outdoor gas unit

Since the floor boiler has a considerable weight, the surface should be prepared for it:

- for the strength of the base, the floor must be poured with a screed, as well as bonded by a non-aggravated coating;

- pay attention to the walls: If it is covered with refractory material, the boiler can be moved close to it, otherwise, place the device at least 10 cm;

- one of the basic requirements is that the boiler must be installed absolutely smoothly.

After preparing the basis, you must perform the following actions:

- Making the installation of chimney and pipes of the water pipeline.

- Then set a threaded coupling with a filter cleansing water.

- After that put ball valves.

Installation of a wall gas boiler

Before moving directly to the installation, it is necessary to free the internal tubes of the unit from the garbage. To do this, remove the caps from the boiler and passing water through them, clean from possible pollution. Further order of action looks like this:

- The wall on which the installation of the boiler is planned, must be durable and smooth. It establishes the planks on which the boiler will be attached.

- If necessary, you need to attach a non-combustible gasket, the width of which should be at least 3 mm. In this case, the distance between the wall and equipment should be at least 4.5 cm. Between the boiler and other existing equipment, the distance must be at least 20 cm.

- Modern gas boilers are equipped with identically located nozzles that are designed to connect to heating, water supply and gas pipelines. The design fragment serving to connect to the gas pipeline is located at the bottom of the boiler.

- On both sides of the aggregate, as a rule, there are taps for water. On the end of the gas boiler, nozzles are placed for connecting to the heating system.

Installation of a wall gas boiler is presented in video:

Connecting the boiler to the gas pipeline

After installing the gas boiler, the next step is to connect to the gas pipeline. In this paper, it is necessary to show a special vigilance, since non-accurant actions with a gas pipeline can lead to severe consequences. The connection process looks like this:

- Initially, it is necessary to connect the pipe that is located on the boiler with a branch of the gas pipe where the crane and valve is located.

- In the following, it is necessary to establish a filter on a crane that cuts off the flow of gas. This will protect the device from the possible garbage.

- Then you need to take care of the seal of the gas pipeline itself and its connections with the boiler. To do this, it is recommended to use the pass or paint. This work stage in the process of connecting to the gas pipeline cannot be ignored, since gas is easier and leakage may occur during damage to the pipeline.

- After that, you can proceed to the installation of filtration elements developed by a special flexible compound scheme. It is worth considering that this purpose is strictly forbidden to use rubber hoses. The porous structure of this material has the properties to rear and crack, the consequence of the separation of gas appears.

- At the end of operation, you need to connect hoses and boiler nozzles. To do this, you need to install precipitated nuts and pads from the pairs, allowing you to seal and seal joints. The use of pads will create additional protection and eliminate possible emergencies.

Connection of the boiler with water supply system

According to the requirements for the installation of the gas boiler, the connection of the device with the water supply system has the following features:

- Connecting an aggregate to the water supply contour is similar to the procedure for connecting the heating system. The difference is only the type of cranes and the diameter of the pipes used.

- In the process of supplying cold water, it is necessary to take care of the installation of special filters that will prevent ingress in the gas boiler of all sorts of contaminants.

- To cut off the plug circuits, you need to use cranes with detachable connections. This requirement is necessary to simplify the installation process and the possibility of operational replacement of the crane if such a need appears.

- The pipes for the supply of cold water should be located on the left side, and for the supply of hot - with the right.

Important! By fulfilling all the installation work on the installation of a gas boiler, for security purposes, it should be carefully checked to check the quality of installation:

- nowhere should have gas and flow water;

- if fluid flow can be immediately defined by a visual inspection, it is possible to detect gas leakage using a soap solution. You need to wet the passing highway and trace so that there are no air bubbles. Their presence testifies to malfunctions.

Safety during operation

So that in the process of operation of the unit does not face dangerous situations to consider several points:

- The boiler should have a sufficient influx of air. Since its deficiency leads to insufficient fuel moisten. The result of such a phenomenon is the formation of a carbon monoxide, which carries a significant danger to human health.

- No less risky situation may occur if the burner spontaneously roasts. This may be provoked by the extrusion of the stamp, the gas pressure drops below the permissible norm, the absence of thrust in the chimney, as a result of which gas flows into the dwelling. In such a situation, it is necessary to overlap the gas supply to the burner.

- Many gas units are equipped with a flame presence control sensor, a device for turning off the boiler in the absence of a power supply. Also, boilers are often equipped with a thrust control sensor and a device that blocks the device in case of gas disconnection.

Important! If the gas boiler has successfully passed the check, it can be commissioned. But it is necessary to do this in the presence of gas workers. If you neglect this condition and launch the equipment yourself, in the future the resolution of the relevant authorities you will not receive.

In addition, if you installed a gas boiler on your own, connected it to water supply systems, gas supply, heating - the presence of qualified specialists is necessary for your safety. It should always be remembered that gas treatment does not tolerate flaws.

Video instructions on the start of the gas boiler are presented below: