Installation of soft roof Construction

The roof is not only a reliable protection against atmospheric precipitation, but also a fairly important decorative element of the house. Therefore, the choice of roofing carpet is suitable as responsibly. Among others, the soft roofs have become very popular. This is a national name that covers a fairly large group of building materials. Let's talk about their properties and installation methods.

Varieties of soft roof

Under the soft roof, you should understand:

- rolled materials,

- polymer membranes,

- mastic materials

- soft (bituminous) tile.

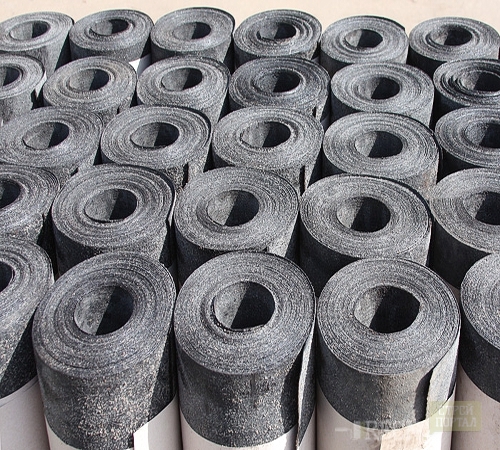

Rolled materials are represented by the Tole and Ruberoid. It is only different from the front roofingoid to its structure and is a roofing cardboard, impregnated with low-wave bitumen mixtures. Between the cardboard and the top coating, a layer of coarse-grained material or sand is made. Tol based on sand is sufficiently short-lived, therefore it is used exclusively as waterproofing. Coarse is used for roofing work.

Ruberoid also consists of roofing cardboard and impregnation. But instead of the inner layer, both edges of the rubberoid are covered with refractory bituminous bases. As a result, such material is rather durable and has increased wear resistance. In order to the roll rolled Ruberoid did not slip, it is treated with a special spript. According to its technical specifications, the division on:

- ruberoid insulating (used as waterproofing),

- euro ruberoid (which covered the roofs).

But in practice it is better to make the choice based on the technical characteristics of the material.

According to the set nomenclature, the marking of the rubberoid consists of three letters and numbers. The first letter "P" is decrypted as Ruberoid.

In second place are located:

- "K" - roofing (suitable for the arrangement of the roof).

- "P" - lining (used as a basis for more durable materials).

- "E" - elastic (duplicates the functions of the lining, in addition, is used as waterproofing).

The third letter denotes the type of sprinkling:

- "K" - coarse-grained.

- "M" - fine-grained.

- "H" - scaly.

- "P" - dusty.

The figure denotes the weight of 1 square. m. Material than it is higher, the stronger rubberoid.

The technology of installation of the soft roof of the use of rolled material with marking RCM - 400 or more, as well as, RKK - 500 or more.

The only drawback is rotting. Therefore, the roof from the rubberoid must be treated with antiseptics at least once every three years. It is applied to the arrangement of a flat roof is rather more likely with an unsightly appearance than with technical standards.

Polymer membranes appeared quite recently and have already begun to outstrett the rubberoid. They are made of polyvinyl chloride, do not rot, and only to a small degree are exposed to temperature effects. This significantly extends the service life. In addition, the cost of mounting the soft roof from this material will be cheaper from this material. The membranes are divided into three types, depending on the basis:

- PVC,

- TPO

- EPDM.

PVC membranes most often found in the domestic market. This is due to the fact that the material includes special plasticizers that withstand Russian frosts. Consist of a reinforcing grid, which is poured with a liquid mixture of polyvinyl chloride. Unfortunately, this material has the stated service life of up to 20 years, which in practice it is often reduced by 10-15 years.

Thermoplastic polyolefins or TPO are manufactured with the addition of rubbers. This allows you to significantly extend the service life (up to 40 years). In practice, such roofing membranes are strongly susceptible to mechanical damage.

Ethylene propylene diene monomer is the most high-tech material for membranes. It allows you to reduce the thickness of the coating of only 1.15 mm, in addition, it is absolutely not subject to temperature drops. EPDM membranes have a practically not limited service life (about 80 years) and do not require any care. It is possible to damage the mechanical way only purposefully cutting the coating. The only drawback is a high price.

Rules for mounting the soft roof allow the use of this material solely for flat roofs.

The latter and most commonly used roofing carpet for a flat roof protrudes motors. This material is a mixture of various bitumen, resins, special additives and antiseptics. Allows you to create perfect waterproofing and easy enough to work.

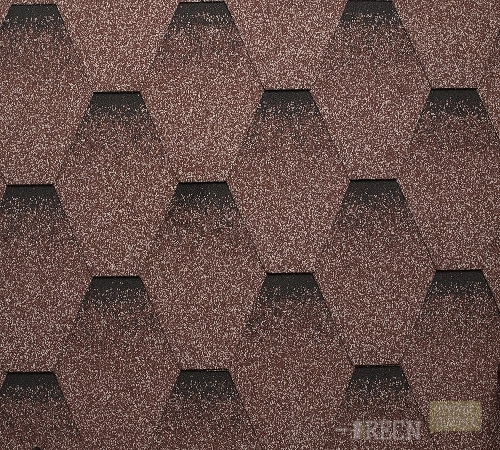

To mount the soft roof on the pitched roofs use bitumen tiles. It is loved by both builders and architects. This is primarily associated with the elasticity of the material and the simplicity of installation. But, if the quality of previous coatings was determined by the chemical composition, then with bituminous tiles are more serious. Given the huge number of manufacturers and various distributors, the optimal option is to select a proven and high-quality manufacturer. By the way, it is worth noting that the deadlines for the installation of the soft roof and the price of this issue at the invitation of specialists will directly be driving from the quality of bituminous tiles. Experts recommend:

- TEGOLA,

- Katepal

- IKO,

- CERTAINTEED,

- Ruflex

- Shinglas.

Among European companies in the domestic market are the Italians Tegola and Finn Katepal. The Italian product is high enough, but still more suitable for the European climate. Bribes the richest model range. Finnish products, on the contrary, sufficiently single type, but withstand any frosts.

Market leaders are American companies IKO and CERTAINTEED. Of the advantages - an acceptable cost, the presence of a fairly wide model range and the highest quality standards.

Recently, the production of bituminous tiles is engaged in Russia. Products of Ruflex and Shinglas companies are practically no difference in quality. Designer solutions are not many more firms. It is worth noting that until 2012, Ruflex tile was manufactured in Finland. But now the production is transferred to Russia. The price is lightly overestimated.

Installation of roofing cake

The installation scheme of a soft roof consists of two stages:

- installation of roofing cake,

- installation of roofing material.

What would you do not wing the roof, roofing pie in all cases is done equally. Therefore, consider the process of its installation. Depending on the type of roof, the cake is divided into:

- scanty

- flat.

Consider the arrangement of the scope design. Mounting consists of the following steps:

- assembly rafted

- inner switcher,

- installation of vapor insulation,

- installation of insulation,

- external fusion,

- installation of waterproofing,

- doom

- outdoor clamping plywood or OSB.

Rafters represent design of two inclined to each other at a predetermined angle beams. The angle of inclination depends on what angle should have a slope of a roof (typically 25 0-350). 20-25 cm below the point of connection beam perpendicular beams bind crosspiece (bolt). The length of the beam is equal to the length of the rafters of the roof, plus a 10-15 cm (to the roof of the house stood for wall and protect it from moisture). The rafters are installed at a distance of not more than 50 cm apart. From above they are associated beam, which creates a single solid frame. Under the rafters set support. If you intend to make a high roof, the better to put the support on both edges of the crossbar. Although the soft roof installation and video tutorials on this subject is not always recommended to install the support, for your own peace of mind it is better to deliver.

Once assembled truss box, move to the inside of the sheet set. For this fit any hem board (the thinner the better, as less). The inner fence filing performs the function for insulation and provides a basis for waterproofing. Therefore, buy thick board makes no sense. The spread between the boards to be 10 cm. Hundredths conventional nails (length 10 cm) was used for mounting.

Vapor is a special film which prevents moisture formed inside the cake. It is attached to the inner (or outer, is not important) side by means of binder stiplera construction. This work must be performed carefully and drive bracket on the first try. If this does not happen, you need to score bracket with a hammer, but not remove, as it violates the insulation characteristics.

Next, put a heater. It is best to fit the foam or polyurethane foam. Foam warmer, but not always close the voids in hard to reach places. To fix this, some sheets crumble and fall asleep in the corners or other bends.

The outer casing serves as a basis for waterproofing. Hem board must be flat. In order not to damage the roll insulation materials, outside of the grind from the large burr. Luft roll waterproofing up to 5 cm, for any other is not allowed.

The process of waterproofing assembly depends on its type. Roll film materials are attached as well as a vapor barrier, bitumen and membrane glued. Liquid foundations are applied according to instructions.

The shap is done to sew plywood or OSB sheets. At the beginning, the beams are fixed with a cross section of 5x5 cm parallel to the roof of the roof, then the same beams are placed perpendicular to the distance not more than 1 m from each other.

As soon as this work is made, go to the final part of the cake assembly and secure the foundation for mounting the roof of soft tiles.

As for flat roofs, they are usually concrete overlaps. Therefore, the cake is much easier.

- The surface is treated with an antiseptic.

- Put the substrate (rubberoid or only).

- Covered with adhesive mastic.

- Once again, the surface of the antiseptic is passed (in order to completely exclude the possibility of the appearance of fungus).

Now consider in detail how the installation of a soft roof is done with your own hands.

Soft roofing installation. Instruction

To systematize the process, the instructions are divided into three parts:

- installation of rolled materials and membranes,

- installation of liquid bitumen materials,

- installation of soft tiles.

Consider each of them in more detail.

Ruberoid and membranes are easy to install themselves. But for the fulfillment of this work, there will be at least three people. The process looks like this:

- the first rolls the roll,

- the second poured under it and smoothes the adhesive mastic,

- the third smoothes the surface of the roofing material.

The speed of performance depends on how much the width and length of the roll are exactly the width. Naturally, it is easier to work with wider rolls. They are from 0.8 to 12 meters. But when placing a roll with a width of more than three meters, you will need another person who will ram the coating. Rolls with a width of 6 or more meters fit in an industrial way. How much is the installation of a soft roof with the involvement of equipment? It is quite expensive, it is advisable to use only at objects with a total area of \u200b\u200bmore than 300m 2.

Installation of liquid bitumen material is carried out either by pouring, or with the help of aerosol spraying. The filler bitumen mixtures are sufficiently thick, so they need to ram. One person is enough to perform work. The aerosol method is much easier, but more expensive mastic and special equipment will be required for it, which is rarely leased. Buy it separately expensive. Therefore, if the work is one-time, it is better to spend a little more time and buy ordinary filler bitumen.

Installation of the roof of a soft roof using bitumen tiles is performed both alone and several people. It is most convenient to work together. One from one slope, the other from the second. If the roof is a single, the second person will need to serve the necessary tools. The work consists of the following steps:

- installation of lining carpet,

- installation of flexible tile,

- installation of ventilation linings and chimney elements,

- installation of the cornice bar.

To work, you will need the following inventory:

- hammer,

- nails,

- screwdriver,

- screws,

- boat

- metal scissors,

- construction Slap,

- adhesive mastic.

Installation of the roof of soft tiles begins with styling the substrate. It feels directly on the crate and fixed along the edges of the stiplier. Roll more conveniently standing on the skate, then the roll itself unwinds rolling down the roof.

Next, we process the substrate with adhesive mastic and fix the sheets of flexible tile. On the edges of the sheets need to be fixed using nails so that they do not slide until the adhesive mixture is drying. Any bituminous tile has a technological groove that serves as a place for fastening and overlapping the next strip. Technological grooves must be missed by adhesive mastic. There are several continuous bands. In the future, they will not only bind two stripes of tile, but also to perform a waterproofing function.

When with the main work is completed, all the necessary additional details are assembled. These can be decorative elements of ventilation mines or chimneys. To install adhesive mastic use.

The last stage is the fastening of the cornice plank. It is made of metal, so screwed with screws.

Soft roofing and editing technology, look below.