Installation of PVC ceiling panels Ceilings

Panels from polyvinyl chloride material today are a fairly common material for finishing the surface of the walls, as well as ceilings. Such a tendency of the growing popularity of the material is explained by its affordable cost, as well as the ease of installation. To perform the trim using this product, you do not need to have any special knowledge and skills in the construction of construction. This task is even a newcomer, if you follow the conditions for the sequence of the technological process.

Content

Features of the material

The glossy and matte ceiling panels PVC are distinguished. Matte products do not have coatings, while glossy are covered with a special composition of varnish. Today, in the construction market, you can find a huge variety of panels, which differ in color, sizes, texture and drawing. With the help of such plastic products, finishing loggias and balconies, as well as cladding ceiling structures in kitchen rooms, bathrooms and hallways.

PVC panels have a number of distinctive characteristics that determine their widespread use when finishing the premises:

- If any communication takes place on the ceiling, the panels easily disguise them. In addition, in PVC, the material will not be difficult to establish point lighting, as well as mount chandeliers.

- For such panels, moisture makes no danger, since they do not relate to the category of hygroscopic materials.

- Also products have significant dignity - environmental safety, since during combustion or elevated air temperature panels do not distinguish harmful substances.

- An important factor is the simplicity of care. In the presence of pollution, even such as fat stains or soot, ceiling plinth for PVC panels can be wiped with a sponge using a traditional detergent.

- In addition, the product does not absorb unpleasant odors.

- As an advantage should also be noted the simplicity of the material installation.

- PVC ceiling panels, the price of which is available to customers of the middle segment, also perform a decorative function. They will help hide defects and ceiling overlapping errors.

PVC panel selection parameters

Choosing a product, you need to consider a number of such parameters:

- First, inspect its surface. The appropriate quality panel should not have irregularities and any distortion of the pattern.

- Note also on the available number of rigid ribs inside the product. The presence of a larger number of such parts is the criterion of strength and good operational parameters.

- Then the docking records should be determined. To do this, it is necessary to connect two panels accordingly - with a high-quality connection, the gaps should be missing.

- An important point is the strength of the material. To choose a good panel firmly squeeze it. If the product is noticeably deformed, and even more so cracked, its qualitative characteristics are doubtful. You do not have such products.

- In addition, check the bending panels. Bend and break the corner of the material 3-4 times. If the product is not cracked, it speaks of high quality. If the panel cracked or broken, the material will not last long and may be damaged due to any effects of mechanical nature.

- Also choosing the panels, pay attention, does not come from the product an unpleasant smell. If such a phenomenon is observed, ask the seller to present a certificate of quality, since the presence of an unpleasant smell may indicate a fake.

Distinguish with suture and seamless panels. In the first case, when combining products, the image of the lining is created, in the second version there are no seams. The facial surface of the material is decorated with a pattern, and the image may be the most diverse. This may be, for example, imitation of wood or natural stone. Such a variety makes it possible to choose the material to almost any room design.

PVC ceiling panels:

Elements of the ceiling construction

To prepare the required amount of material for installation, all components of the ceiling should be determined. The composition of the ceiling cover includes such elements:

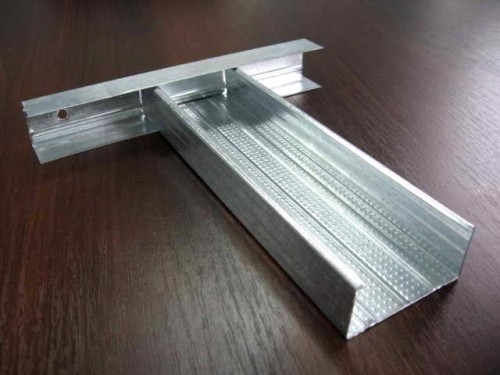

- frame, which is attached to the ceiling and represents the basis of all installation. It can be metallic or made of wooden bars;

- ceiling plinth;

- corners, which are drawn by connecting places of plinths;

- directly panel PVC;

- details for fasteners of plastic. In this case, these are galvanized self-tapping screws that have a press washer with 25 mm.

Calculation of material

To determine how much material will be required for mounting the PVC ceiling panels, it is necessary to make the correct calculation of the parameters of the room:

- First, determine the ceiling area. For this purpose, we multiply the length of his sides.

- Further, the calculated digit is divided into one panel area, which can be found by looking at the packaging of the material.

- The data obtained and will be the necessary amount of material. But it is recommended to add another 20% for possible cuts.

- In order to understand how much polymer profiles are necessary for mounting, make a chart of the ceiling surface. Then apply the lines located on one side parallel to each other. They will serve as a markup for fastening the profile, the space between which should be 50 cm.

Determining the amount of fasteners on the PVC ceiling panels and its dimensions, it is necessary to proceed from among the mounted profiles to the ceiling surface. To make it you need to proceed from such a quantity: 1 dowel is 0.5 meters of profile. And also you should prepare a self-tapping screw, preferably with wide hats, which will be necessary for fastening PVC products to the profile. Calculate the number of self-samples must be based on the calculation: 1 unit by 0.5 Length of the PVC bar.

PVC Mounting Technology on Metal Frame

Installation of ceiling slats on a tin frame occurs in the following order:

- We begin the process from the markup of the profile fastening lines along the ceiling surface perimeter. We carry out this with the help level. The profile to the wall should be fixed in such a way that there are no slots and gaps.

- Now on the planks that are already fixed, install a transverse profile.

- In the next, the L-shaped profile is set to panels that are fixed around the ceiling perimeter.

- Then proceed directly to the installation of PVC panels. Work start from the wall. With the help of fine knobs, cut off the desired length of the material.

- Next, insert panels into the profile and fix with the help of screws.

- We continue to work, tightly inserting the following panels one to another, and fastened to the profile rake.

- When installing the last panel part, you should adjust its width to the remaining distance to the wall surface.

Installation on a frame of wooden bars

To fix panels on a frame of wooden bars, you need to prepare the following:

- bars measuring 20x40 mm;

- nails;

- final element;

- mounting shelf.

The process of fastening the PVC ceiling panels is as follows:

- Fix the wooden bars perpendicular to the mounting panels.

- Further fix the final fragment.

- Then we insert the first bar in the groove of the installed final part.

- After that, with the help of nails, a wide assembly shelf of the product to the bars.

- The next panel product is inserted into the groove of the first.

- Perform the fixation of the panel using it for this nails.

Thus, we continue to install the material, attaching each subsequent part to the previous panel. However, before installing the last product, it follows 6 mm to reduce the size of the mounting shelf. After that you need to insert the product in the groove of the old panel.

Recommendations for installation and operation of panels

- Before mounting the panels on the ceiling, the surface should be carefully cleaned from contaminants.

- In rooms where heightened humidity is observed, it is not recommended to mount panels on a wooden frame. Otherwise, with time, the framework under the influence of moisture is deformed and the curvature of the ceiling surface will occur.

- Ceiling height criterion are installed lighting. The ceiling height should be descended depending on the placement of lighting devices.

- Before the installation process, the electric wiring should be mounted under the ceiling.

- To combine plastic panel products, different from each other by color or size parameters, you should use connecting elements designed specifically for this.

- In the process of care, it is not recommended to use synthetic and organic solvents. Under their impact, the material may be damaged.

A video clip on the installation of panels can be seen below: